ผู้เชี่ยวชาญด้านการผลิตและการวัดค่าความหนืดผลิตภัณฑ์โพลิเมอร์และน้ำมันทุกชนิด (Automatic Polymer Viscometer) ตามมาตรฐาน ASTM D445, D789, D1243, D1795, D4020, D4243, D4603, ISO307, ISO1157, ISO1601, ISO1628-2, ISO1628-5, ISO1628-6, ISO3105, DIN51562-1, DIN54270, JIS K-6722, K-6920-2 เป็นต้น นอกจากนี้ยังมีเครื่องเตรียมตัวอย่าง (Sample Preparation) และมีระบบการจัดการการทดสอบตัวอย่างต่อเนื่องแบบอัตโนมัติ (Automatic Sample Changer) พร้อมซอฟแวร์ประมวลผลสำหรับอำนวยความสะดวกให้แก่ผู้ใช้งานในการคำนวณค่าความหนืดแบบต่างๆ พร้อมฐานข้อมูลทางด้านงานโพลิเมอร์แบบครบวงจร ตัวเครื่องทำงานด้วยเทคโนโลยีอันทันสมัย และมีทีมงานผู้เชี่ยวชาญจากเยอรมันในการให้คำแนะนำการใช้งานและการบริการหลังการขาย

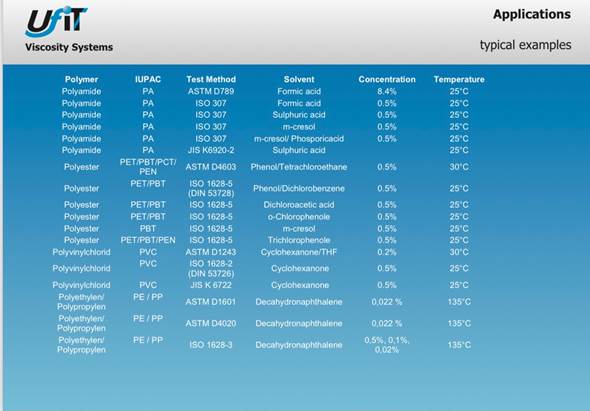

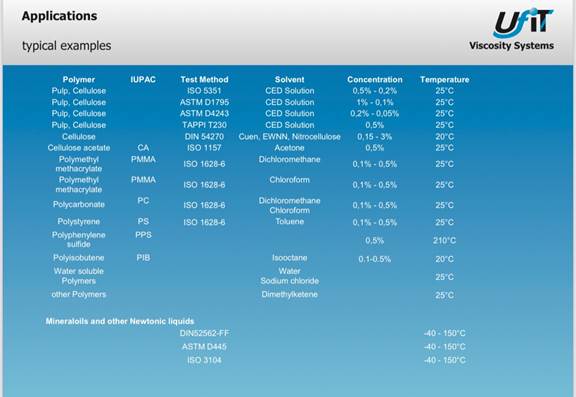

UVS® measurement devices are developed to measure the intrinsic viscosity of polymers as well as the kinematic viscosity of mineral oil products in compliance with DIN51562 p.1-3, ASTM D 445/446 and DIN ISO EN 3104/3105 and all polymer standards (see Application Table). Example of compliant test standards.

- ASTM D445, D789, D1243, D1795, D4020, D4243, D4603

- ISO307, ISO1157, ISO1601, ISO1628-2, ISO1628-5, ISO1628-6, ISO3105

- DIN51562-1, DIN54270

- JIS K-6722, K-6920-2

- Tappi T230

- All valid standards concerning testing of polymers

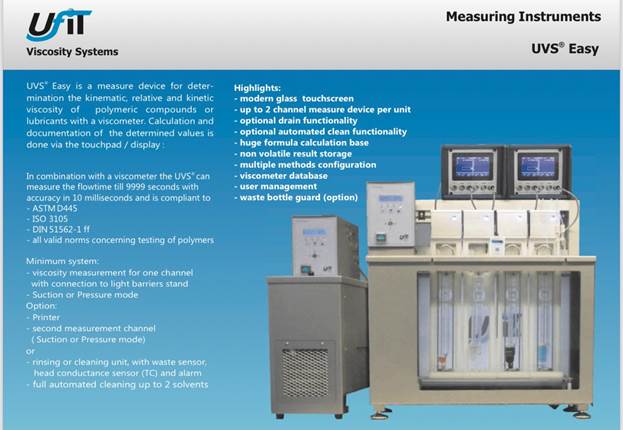

UVS® is a measure device for determination the kinematic, relative and kinetic viscosity of polymeric compounds or lubricants with a viscometer. Calculation and documentation of the determined values is done via the touchpad / display. In combination with a viscometer the UVS® can measure the flowtime till 9999 seconds with accuracy in 10 milliseconds.

UFIT provides two lines: UVS® Easy and UVS® Basic

General features

- High precision time measurement

- Reproducibilty of flow time

- High precision constant bath

- Space saving

- Modular concept

- Customized configuration

- High viscosity handling

- Resistant against acids and any solvent

- Infrared and thermistor detection

- Safety light barrier control

- Support of suction and pressure mode

- Channel independent measurement

- Modern glass touchscreen

- Manual filling

- 1 or 2 measure points

- Semi automated cleaning

- Full automated cleaning with up to 2 solvents

- Printer connection

- Modular

- Expandable

- Up to 128 measure points to fully automated system with sample changer

- LIMS connectivity

- PC Connection

Minimum system:

- Viscosity measurement for one channel with connection to light barriers stand

- Suction or Pressure mode

Option:

- Printer

- Second measurement channel (Suction or Pressure mode)

- Rinsing or cleaning unit, with waste sensor, head conductance sensor (TC) and alarm

- Full automated cleaning up to 2 solvents

Main Highlights:

- Modern glass touchscreen

- Up to 2 channel measure device per unit

- Optional drain functionality

- Optional automated clean functionality

- Huge formula calculation base

- Non volatile result storage

- Multiple methods configuration

- Viscometer database

- User management

- Waste bottle guard (option)

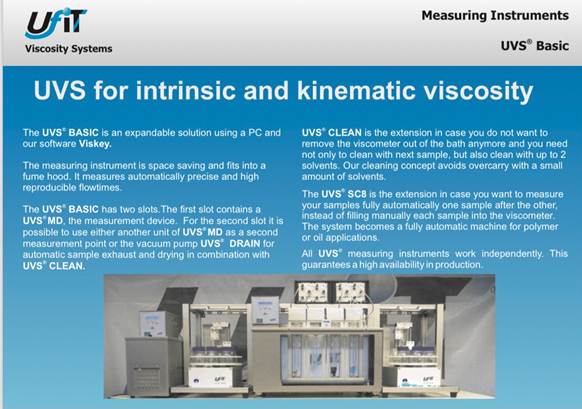

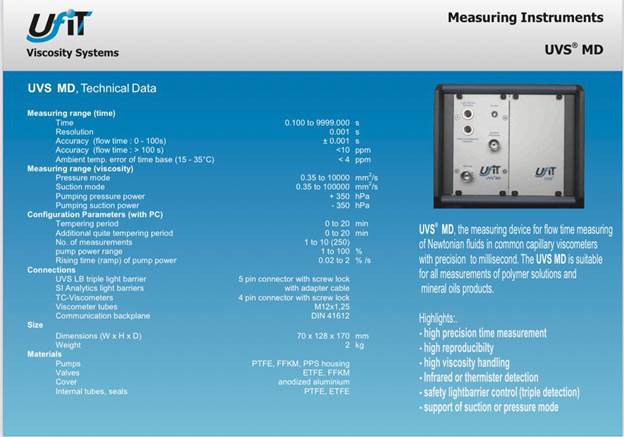

UVS MD – Measuring Device

UVS® MD, the measuring device for flow time measuring of Newtonian fluids in common capillary viscometers with precision to millisecond. The UVS® MD is suitable

for all measurements of polymer solutions and mineral oils products.

Highlights:

- High precision time measurement

- High viscosity handling

- Infrared or thermister detection

- Safety light barrier control (triple detection)

- Support of suction or pressure mode

UVS® NoLimits

High speed intensive cleaning and drying module by using vacuum and pressured air

UVS® NoLimits automated cleaning and half automated charging. This device controls pre-dilute and discharging of the sample, rinsing with up to 2 solvents and drying of the whole system.

The intensive cleaning procedure reaches UVS® NoLimits is responsible for full automated cleaning and semi-automated charging. This device controls pre-dilute and discharging of the sample, rising with up to 2 solvents and drying of the whole system. The intensive cleaning procedure reaches the complete viscometer with all parts of the system like tubes and sample needle. UVS® NoLimits also supports the sample transfer to the viscometer in a save way and avoid personal contamination of hazard substances during the filling. UVS® NoLimits is especially developed to handle samples in a wide viscosity range. Of course all parts are chemical resistant against all kind of organic solvents like acetone, chloroform and toluene. In case of using strong acids we provide a solution on request. UVS® NoLimits is suitable for Ubbelohde and Cannon-Fenske-Routine viscometers in accordance to ASTM D446 / ISO3104. For samples like used motor oils a TC-Ubbelohde is strictly recommended.

UVS® DRAIN

UVS® Drain, the device is responsible for automated cleaning. This device controls the discharging of the sample, rinsing with solvent, drying and discharging the solvent to the waste bottle. Sensor detection for a full waste bottle complies safety requirements. The cleaning process can be optimzed by configuration to save time and get best results.

SAMPLE CHANGER – SC8

UVS® SC8, the sample changer with 8 and respectively 24 positions in dependance of the sample bottle size. With integration of a UVS® SC8 the UVS® Basic becomes a fully automatic machine. The sampler can serve one or two viscometers. In case of two viscometers the filling and rinsing procedure works in an alternating operation mode. The turntable is available for common laboratory 100 ml sample bottles, 50 ml centrifugal tubes, 30 ml disposable PP beakers and 20 ml micro tubes. An adaption of individual sample vessels are possible on request. Depending on the stage of extension - 2x UVS® Basic and 4x UVS® SC8 - the system has up to 96 sample positions and can measure up to 80 samples per hour.

The rinsing of the sample transfer tube and piston pump is realized by the

module UVS®( RM supporting 2 solvents, a rinsing and a drying solvent. Rinsing with next sample is also configurable. There is a maximum of rinsing logic to avoid any carryover and saving solvent at same time.

The used valves are chemical resistant and have a lean dead volume. Sample filtration with filter backwashing is available as an option for low viscous samples. A sensor recognizes

VisKey - The Key to Viscosity / Control and Evaluation Software

What Viskey can do?

- Calculation of kinematic, dynamic, relative and intrinsic viscosity

- Determination of capillary constant by system calibration, blank value (t0), viscosity index, enzyme kinetic, dilution viscosity

- Formula editor for individual calculations

- No limitation of method numbers

- Each measuring station can work in a different method

- Viscometer database

- User level access-controlled software with three levels: administrator, authorized user, worker

- Access restrictions can be disabled

- Multitasking operations – each measuring point works independent

- Possibility to enter sample ID using a barcode scanner

- Logbook features, CFR21 part 11 compliant

- Result database with screening and sorting functions

- Sample changer functions like priority sample, subsequent addition or removal of samples

- Supported operating system Windows XP,Vista, Win7, Win8

- Supported periphery: UVS Basic, UVS Tower, UVS Clean, SC8

UVS® LB - Light Barriers

UVS LB, the Triple Detection light barrier made of PVDF.

The stand with integrated viscometer fixation is suited for all common

capillaries. Viscometers with fixing bracket are also usable. The

light barriers are working with infrared light and are able to detect certainly the meniscus pass. The third and topmost light barrier is used as "over suck" protection. For measurements with Micro-Ubbelohde viscometers this light barrier can increases the reproducibility of values through constant kept start conditions.

Additional fixation holder for Canon-Fenske Routine, Canon-Fenske

Ubbelohde, Witeg-, Paragon-, Tamson-Ubbelohde available.

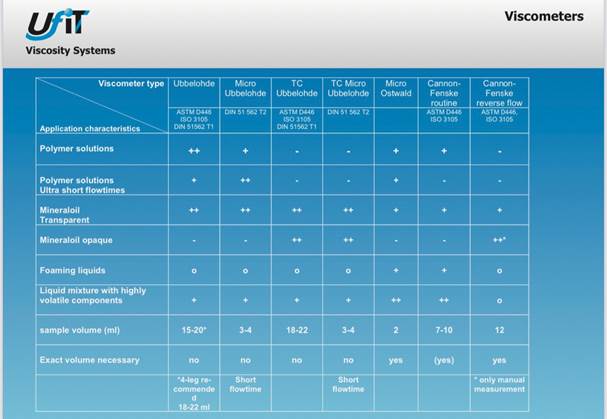

VISCOMETERS

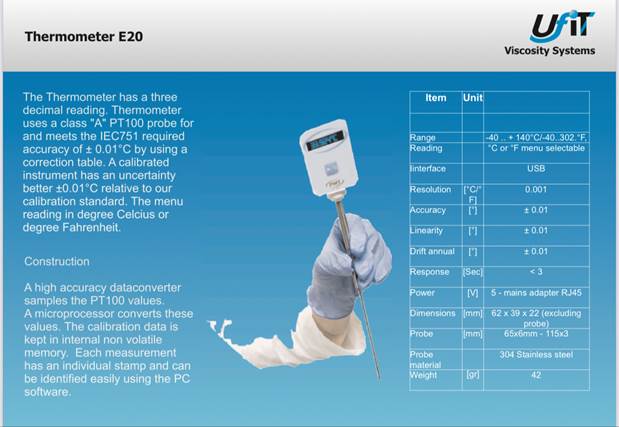

THERMOMETER E20

The Thermometer has a three decimal rading. Thermometer uses a class A, PT100 probe that meets the IEC751 requirements +/- 0.01 deg. C relative to our calibration standard

STIRRING DRYBATH

CONSTANT TEMPERATURE BATH / CHILLER