![]()

Filtertechnik Ltd. เป็นบริษัทผู้ผลิตเครื่องทดสอบ เครื่องนับจำนวนและวัดขนาดอนุภาคของน้ำมัน (Particle Counter) เครื่องวัดระดับความสะอาดของน้ำมัน (ISO Cleanliness Class) ตามมาตรฐาน ISO4406, SAE AS4059 & NAS 1638 เครื่องกรองน้ำมันหล่อลื่น เครื่องศึกษาประสิทธิภาพในการกรองน้ำมัน เครื่องประเมินอายุการใช้งานของน้ำมัน (Oil Life Condition / Oil Condition Monitoring) การใช้งานเหมาะสำหรับการทดสอบน้ำมันหล่อลื่น (New Oil, In-Service Oil, Used Oil) น้ำมันไฮโดรลิก น้ำมันเบรก น้ำมันสังเคราะห์ น้ำมันดีเซล น้ำมันเครื่องบิน น้ำมันเชื้อเพลิง ตัวทำละลาย สารเคมี และของเหลวอื่น ๆ มีให้เลือกทั้งแบบทดสอบนอกสถานที่ (Portable Particle Counter) แบบตั้งโต๊ะสำหรับห้องปฏิบัติการ (Laboratory Particle Counter) และแบบทดสอบต่อเนื่อง (Online Particle Counter) ตัวเครื่องทดสอบแบ่งออกเป็นสองประเภทตามลักษณะของเซ็นเซอร์ที่เลือกใช้ ได้แก่ Laser Particle Counting / หลักการการบังแสงหรือดูเงาการตกกระทบของอนถภาค และ Digital Imaging Particle Counting / หลักการวิเคราะห์ด้วยภาพดิจิตอลที่พัฒนามาเป็นพิเศษสำหรับตัวอย่างที่มีปัญหาการปนของฟองอากาศ ทำให้ไม่สามารถวัดค่าขนาดและนับจำนวนได้ถูกต้อง นอกจากนี้มีระบบจดจำรูปร่างของอนุภาคโลหะที่เกิดจากการสึกหรอระหว่างการใช้งาน เช่น Fatigue Wear, Sliding Wear, Cutting Wear, Fibres เป็นต้น และสามารถต่อเข้ากับเซ็นเซอร์เพื่อวัดปริมาณความชื้นสัมพัทธ์ในหน่วย %RH (ในกรณีที่ใช้วัดน้ำมันหล่อลื่น) และค่าความชื้นในหน่วย PPM (ในกรณ๊ที่วัดน้ำมันดีเซล)

OIL CONDITION MONITORING

Digital Imaging Particle Counters

Particle Pal Range

With 25

years’ worth of expertise and innovation, our multiple award-winning Particle

Pal products are modular designs utilising a wide range of sensors to suit

individual testing requirements.

Filtertechnik offer two particle counting options: Laser Counters or Digital

Imaging, which is a more advanced particle counting technology with a wide

range of benefits (see more below).

There are currently 16 product variations, use our selection guide below to

refine your search in order to find the best Particle Pal for your application.

Particle Pal Pro: V3

Our Particle Pal Pro range, harnesses advanced digital imaging particle counting technology and offers a broader micron range up to 70 microns. The powerful CMOS camera can recognise the shape of each particle, which then categorises it into either fatigue, sliding or cutting wear to help pinpoint root causes of system failure. Along with ground-breaking air bubble detection/elimination, there is also the ability to handle higher viscosities up to 2,400cSt. Digital Imaging is not affected by oil additives. Add other sensors such as Water Sensing, Oil Life determination and Viscosity to give incredible insight into the condition of your oil or diesel fuel.

The Pro Range also prides itself on an onboard asset management tool, which is pre-installed on each Pro model as standard. The Asset tool allows users to trend, analyse and interoperate data like never before. Learn all about it in the short video on this page.

Particle Pal Plus: V4

The latest addition to the family: the all-new Particle Pal Plus. The Particle Pal Plus incorporates all the benefits of digital imaging particle counting into a compact case, offering a low-cost alternative to Pro. Full-spectrum ISO counts, bubble elimination plus ISO counts are not being affected by phantom particles/oil additives, which is a known issue with laser technology.

Particle Pal Plus is modular and can be built with an array of different sensors for a deep insight into oil and fuel health. Two pump variations are available, a standard gear pump that can be used on viscosities up to 320cSt or the high viscosity version (HV) up to 2,400cSt.

Digital Imaging Particle Counter

Particle Pal Pro - Digital Imaging Portable Particle Counter

Particle Pal Pro + Water Sensor - Digital Imaging Portable Particle Counter

Particle Pal Plus: Digital Imaging Portable Particle Counter

Particle Pal Plus + Water RH%: Digital Imaging Portable Particle Counter

Particle Pal Plus + Water PPM: Digital Imaging Portable Particle Counter

Particle Pal Plus + Water PPM and Density Sensor: Digital Imaging Portable Particle Counter

Particle Pal Plus High Viscosity: Digital Imaging Portable Particle Counter

Particle Pal Plus High Viscosity + Water RH%: Digital Imaging Portable Particle Counter

Particle Pal Plus High Viscosity: Particulate, Water RH%, Viscosity and Density

Particle Pal Pro + Viscosity - Digital Imaging Portable Particle Counter

Laser Particle Counters

Particle Pal - Laser Portable Particle Counter

Particle Pal + Water & Density Sensor - Laser Portable Particle Counter

Particle Pal: Life - Laser Portable Particle Counter: Including water and remaining oil life sensor

Understanding Phantom Particle Counts

Filtertechnik have developed a portfolio of products for accurate real-time monitoring of Particulate, Water Content and Remaining Life for Oil and diesel fuels. We offer 2 particle counting approaches, new Digital Imaging technology and more traditional Laser Particle counters.

S120 Digital Imaging Particle Counter

The S120 Digital Imaging Particle Counter is a huge step forwards in accurate determination of oil and diesel fuel Particle counting using revolutionary new digital imaging and advanced algorithyms to analyse particles on the fly. A wider particulate size categorisation (4, 6, 14, 21, 38, 70 and >100 microns are counted and categorised) as well as shape recognition sorting particles 20 microns and above into; Sliding, Cutting and Fatigue Wear. An additional major feature is bubble recognition and elimination from ISO counts.

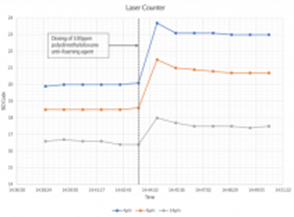

Filtertechnik have conducted extensive testing of both Digital Imaging and

Laser counting when Siloxane based anti-foaming additives are present in

mineral oil, especially polydimethylsiloxane, a common additive to hydraulic

oils. This additive causes phantom

particle counts with laser counters but not

with digital imaging. For more information on this phenomenon please

click here.

Particle Pal Pro

Utilising Digital Imaging

S120 Digital Imaging

Particle Counter

Get a deeper insight into oil health

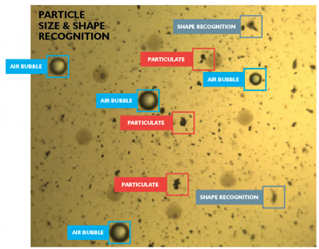

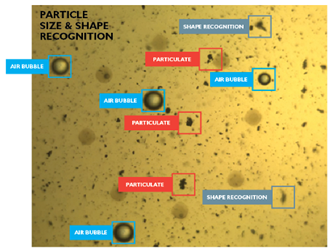

The revolutionary new Digital Imaging particle counting technique gives unprecedented insight into the type and quantity of contamination in any given oil or diesel fuel sample. ISO/NAS/SAE counts as well as a broader micron range, shape recognition, bubble elimination and the ability to handle higher viscosities.

This breakthrough technology uses advanced algorithms to calculate the size and shape of particulate on images taken at between 2 & 4 frames/second. The technology also gives root cause shape recognition to the particulate in live systems or bottle samples of any oil. Special algorithms and AI analyse images on the fly with a resolution of 2 microns up to several hundred microns. High-resolution images are saved for further analysis and reporting such as the one above.

Particles are counted and categorised into Fatigue, Sliding or Cutting Wear. Air Bubbles and Water Droplets are counted and then eliminated from the counts making this suitable for live testing or permanent installation on systems where air is present such as large gearboxes. In addition, anti-foaming additives such as polydimethylsiloxane are not counted as particles by digital imaging, this is a major advantage over Laser Particle counters which see's the micelle-like formations created by this additive as contamination, these are phantom particles, often resulting in particle counts being raised by 2 to 3 ISO codes, especially the 4 and 6 micron channels. Filtertechnik supply the S120 counter as a stand-alone particle counter for integration into live systems for 24/7 monitoring. Alternatively, we have developed a range of portable oil analysis cases designed to give on the spot oil analysis and a deep understanding of the type and quantity of contamination in any given oil sample. Built-in software takes readings from the new digital imaging technology and presents Engineers with an easy to understand analysis including images of contamination in the oil sample.

MOISTURE SENSORS

RH Water monitor sensor and display

Water Measurement Sensor WMS500 for Genuine PPM

Filtertechnik offer two types of water sensors for determining the quantity of water in oils, fuels and biofuels; our RH sensors and our WMS500 PPM sensors

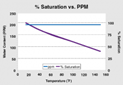

RH Water Monitor: Our RH (Relative Humidity) water monitor gives the percent saturation of a given fluid. 100% saturation is the point at which suspended water becomes harmful free water. These sensors are lower cost and are very useful for hydraulic applications. Outputs are scaled and 4-20mA.

WMS500 PPM Sensor: Our Genuine PPM sensors are highly accurate parts per million (PPM) sensors and are particularly useful for transformer oils and diesel fuels or biofuel. The sensors are calibrated to a Karl Fischer device and fully temperature compensated.

To understand the different relationships between %RH and PPM please see below:

Parts per million (ppm) :

Our PPM sensor gives a count of the absorbed water up to the saturation point of a given oil or fuel. Beyond the saturation point the sensor 'locks out' as free water will have formed.

Relative humidity:

Relative Humidity or RH is expressed as a percentage. 100% RH equates to the maximum amount a given oil or fuel can hold (absorbed water) before it becomes saturated and free water forms.

To view all our quality control and instrumentation click here

UNDERSTANDING PHANTOM PARTICLE COUNTS

The increased use of siloxane based anti-foaming agents is causing issues with laser counter technology.

IMAGINE THIS: You have been filtering 150 litres of hydraulic fluid off-line with staged 5 and 1 micron filter elements at a rate of 25 litres per minute (1,500 litres per hour). You have been using a laser light-blockage method (LBM), automatic particle counter to verify the fluid cleanliness. The starting cleanliness per ISO 4406:2017 was 25/22/15. After eight hours, the cleanliness has only dropped to 22/20/13. You’ve checked that the filter element is not clogged and not in bypass. You even went through the trouble of making sure there was an element actually in the filter. How is this possible? What you’re likely experiencing is a classic case of “phantom” particle counting.

Demystifying phantom particle counts

Phantom particle counting is a documented problem, encountered when using laser-based LBM particle counters to verify the cleanliness of mineral based fluids containing certain insoluble additives. Silicone-based antifoam agents such as polydimethylsiloxane are common additives causing problems. Fluids used in mobile fluid power systems are typically formulated to contain high antifoam concentrations. Research has suggested that through differential surface tension, the silicone-based antifoam additive agents adhere to the inner wall of microscopic, entrained air bubbles, resulting in micelle-like encapsulations of the additive agents that then take on the apparent shape characteristics of a water droplet. The micelle-like antifoam agent encapsulations typically range in 4-10µm in size. Once the encapsulations rise to the fluid surface, the agents quickly pierce the air bubble and return back into the fluid. In a related study on the effects of a variety of nonsolid contaminants and additives on LBM particle-counting accuracy, it was found that a base stock mixture containing 0.02% (by weight) of a silicone antifoam agent increased the particle count by a minimum factor of three. The erroneous particle accounts were particularly evident in the 4µm and 6µm channels of the ISO 4406 cleanliness standard.

Limitations of Laser particle counts

Light blocking method (LBM) Laser particle counters are useful in many applications and the principle of the method is fundamentally simple. Fluid flows through a measurement cell containing a light source on one side and a receiver (photodetector) on the opposite side. The light source becomes partially blocked as particles pass through the measurement cell, creating a light radiation differential (a shadow) – corresponding to the circular cross-sectional size of the passing particles. Because of this fundamental operating principle, LBM particle counters suffer from a key drawback: the inability to discern solid contaminants from other contaminants such as water, air bubbles, phantom particles, and so on. So, how can the phantom particles be overcome using automatic particle-counting technology? There is an alternative solution.

Digital imaging particle counting

Digital imaging particle counting uses size and shape-recognition technology, based on advanced algorithms to distinguish contaminants. For example, a direct imaging particle counter can distinguish contaminants into fatigue, cutting and sliding wear, as well as fibre and air bubble categories based on shape characteristics. It can also recognize water droplets (though water droplets are typically not recorded). The distinction of contaminants allows for more accurate particle counting, by negating nonsolid particles like entrained air bubbles and water droplets.

The S120 digital imaging particle counter can recognise solid particles and summarize them into 4, 6, 14, 21, 38, 70 and >100 micron ranges. It can also recognise shapes and give individual shape recognition counts as sliding, cutting and fatigue wear particles. Bubbles are also recognised and removed from the counts.

Therefore, digital imaging particle counting technology can negate the micelle-like antifoaming additive encapsulations as water droplets – phantom particles – allowing users to understand the condition of their fluids with confidence. Various real-world case studies demonstrate how the Particle Pal Pro a fluid condition monitoring solution with digital imaging particle counting technology, can overcome phantom particle counting.

Laser vs digital imaging particle counter test

In a lab-based test conducted on base oil with no additives, Filtertechnik ran 2 particle counters feeding from the same oil warmed to 40°C. - a laser counter and digital imaging particle counter. Filtertechnik then dosed in exactly 100ppm polydimethylsiloxane anti foaming additive. The results were immediately apparent in the laser counter, affecting the 4 and 6 micron counts by up to 3 ISO codes, the 14 micron count slightly less so, but still an increase of 1 ISO code. The digital imaging counter remained unaffected by the additive.

CASE STUDY

An OEM of large off-highway equipment was experiencing continuous particle counter inaccuracies at a verification stage of assembly. The rejections due to fluid condition were mounting, causing delayed shipments and significant related costs. The average holding time delay due to rejection was seven days, which incurred a holding cost of £1,000-a-day per unit. At the consultation phase of the case study, eight units had been delayed.

The diagnosis was in: the existing laser light-blockage-type particle counters were providing inconsistently high and erroneous particle counts. The ISO 4406 cleanliness would frequently measure 23/22/19, despite a strong fluid-maintenance and conditioning regime. Third-party fluid analysis reports and fluid datasheets suggested that the synthetic hydraulic fluid contained a high concentration of a siloxane (silicone derivative) antifoaming additive, known to cause phantom particle measurements in LBM automatic particle counters.

Filtertechnik provided an extensive on-site demonstration that proved the advanced digital imaging technology of the Particle Pal Pro portable fluid contamination monitoring solution, which measured an average ISO fluid cleanliness of 15/14/10. This allowed the customer to successfully process the fluid and pass six units during the first day of demonstration. The two remaining backlogged units passed early on the second day of demonstration. The savings evidenced by the demonstration equated to approximately 35% in cost savings and an 81% reduction in holding time.

For more information on the Particle Pal Pro click here