ผู้ผลิตเครื่องมือทดสอบทางด้านความปลอดภัยของผลิตภัณฑ์ ตามมาตรฐาน IEC (IEC Testing Standard) เช่น IP test equipment, test fingers and probes, safety test equipment, gauges for plugs, socket-outlets, appliance couplers and lamp holders, equipment for breaking capacity, normal operation and endurance tests of switches, plugs, socket outlets and appliance couplers, equipment for testing resistance to heat, fire and tracking and equipment for checking mechanical strength and mechanical hazards, environmental chambers, including humidity, temperature, dust and draught-proof chambers.

DUST CHAMBER WxDxH 700X1100x600 mm

COMPLIANCE

T1?51 DUST CHAMBER WxDxH 700X1100x600 mm is designed and manufactured in compliance with IEC 60529, 60068-2-68 La2, 61558-1, 61386-23, 60598-1, BS EN 60529, IS 12063 and IS 13947

INTRODUCTION

T1-51 DUST CHAMBER WxDxH 700x1100x600 mm is intended for determining the degree of protection against harmful deposits of dust (IP5X) and against ingress of dust (IP6X). Dust protected enclosures to numeral 5 allow a limited quantity of dust to penetrate under certain conditions. Dust-tight enclosures to numeral 6 do not allow any dust to penetrate.

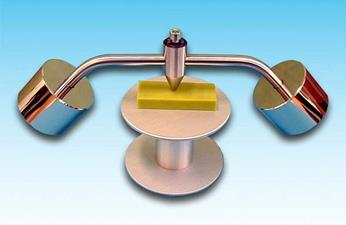

GLOW WIRE TEST APPARATUS

T4-08

COMPLIANCE

It is constructed in compliance with IEC 60695-2-10, IEC 60950-1, IEC 60335-1, IEC 60884-1, IEC 60238, IEC 60695-2-11, IEC 60695-2-12, IEC 60745-1, IEC 60400, IEC 60730-1, IEC 60598-1, IEC 61050, IEC 60320-1, IEC 61058-1, IEC 60742, IEC 60669-1, UL 746A, BS EN 60695-2-1, BS 6458, NF C20-921-1, IS:11000,EN,TS,SIST…

INTRODUCTION

As it is usually the case with other flammability tests also with this test it is not easy to obtain repeatable results. Therefore we designed GLOW WIRE TEST APPARATUS with goal of improved repeatability of test results and ease of operation. The BOLD features below are some of advantages that were introduced to reach these goals.

TRACKING TEST APPARATUS 600V

T4-41

COMPLIANCE

It is constructed in compliance with IEC 60112, IEC 112, IEC 60335-1, IEC 61058-1, IEC 60065, IEC 60669-1, IEC 60884-1, IEC 60950-1, IEC 61010-1, BS 1363, IEC 60598-1, IEC 60320-1, IEC 60898-1, IEC 60400, IEC 60238, IEC 60730-1, GB4207, GB7000.1, UL746A, DIN53480, ASTM D 3638, VDE 0303, DIN 53480, GB/T 420,

INTRODUCTION

T4-41 TRACKING TEST APPARATUS is intended for determining the degree of protection against formation of conducting paths in solid insulating materials, due to the electric stress and electrolytic contamination of the surface.

This test is complex and the person performing it should be accurate and maintain good cleansiness of test equipment. The repeatability and comparability of test results depend on many different factors. Therefore we designed TRACKING TEST APPARATUS with the following goals:

· Reliability

· Maximum repeatability of test results

· Maximum comparability of test results

· Ease of operation

· Ergonomical design

TIMER WITH THERMOMETER

T3-53

COMPLIANCE

It is constructed and manufactured in compliance with IEC 60695-11-5, IEC 60695-11-2, IEC 60695-11-4, IEC 60695-11-3, ASTM D 5027, ASTM D 5027,

MOTOR DRIVE FOR SPRAY APPARATUS

T1-32

COMPLIANCE

T1?32 MOTOR DRIVE FOR SPRAY APPARATUS is designed and manufactured in compliance with IEC 60529,…

INTRODUCTION

T1?32 MOTOR DRIVE FOR SPRAY APPARATUS is intended for determining the degree of protection, against ingress of water IPX3 and IPX4.

GAUGES AND TEST PROBES

T5-XX

COMPLIANCE

Gauges and test probes are constructed and manufactured in compliance with different IEC, EN, and other standards (IEC 60529, 61032, 60061-3, 60320-1, 60884-1, 60400, VDE 0620-1, BS 1363-1).

INTRODUCTION

T5?XX GAUGES AND OTHER TOOLS is a group of our products that is not easy to define due to its extensiveness. It includes different items (gauges, mandrels, probes, fingers, pins, spheres, tools, devices and accessories) that are intended for determining dimensional compliance of tested samples, electrical and/or thermal and/or mechanical loading and burdening, accessibility of live parts, gauges for testing contact making, “go” and “not go” gauges, gauges for testing protection against accidental contact, gauges for testing contact making, alignment gauges, contact and no contact gauges, gauges for max. and min. withdrawal force checking, gauges for breaking capacity tests, gauges for normal operation tests, gauges for temperature rise measurements, gauges for pulling test, test caps, gauges for insulation resistance testing, different kinds of loading weights, test caps for torque tests, test sockets or plugs, mandrels for bending tests, test knifes, dummy fuse links, minimum and maximum gauges

BALL PRESSURE TEST APPARATUS

T4-03

COMPLIANCE

T4?03 BALL PRESSURE TEST APPARATUS is designed and manufactured in compliance with IEC 60695-10-2, 60335-1, 60950-1, 60884-1, 60320-1, 60598-1, 61010, 61032, 60439-5, IEC 60601-1, BS 1363-1, IRAM 2073, 4220-1 NM, BIS, UL 2601-1, CSA 60745, VDE, BSI, DIN, EN.

APPARATUS FOR PRESSURE TEST AT HIGH TEMPERATURE

T4-29

COMPLIANCE

T4?29 APPARATUS FOR PRESSURE TEST AT HIGH TEMPERATURE is designed and manufactured in compliance with IEC 60884-1 Figure 41, 41a, 41b and BS 1363-1.

HEATING CHAMBERS WITH FORCED CONVECTION – EASY

SPXXE

COMPLIANCE

It is constructed in compliance with IEC 60335-1, IEC 60065, 60950.

INTRODUCTION

Hearing chambers are intended for performing different kind of test where the temperature of must be controlled within certain limits.

Heating chambers were designed with the following goals:

· Safety

· Reliability

· Ease of operation

· Ergonomical design

CLIMATIC CHAMBERS

KKXX

COMPLIANCE

It is constructed in compliance with IEC 60335-1, IEC 60065, 60950.

INTRODUCTION

Climatic chambers are intended for performing different kind of test where the temperature and humidity of sample environment must be controlled within certain limits.

Our climatic chambers were designed with the following goals:

· Safety

· Reliability

· Ease of operation

· Ergonomical design