Lagge Technologies เป็นผู้เชี่ยวชาญในการผลิตเครื่องทดสอบค่าความหนืดของเยื่อเคมี เยื่อเซลลูโลส และเยื่อฟอก (Pulp Viscometer) ตามมาตรฐาน ISO 5351/SCAN-CM 15

Lagge Technologies AB is a Swedish technology company, founded in 1942, having many years of experience in developing and supplying complete industrial hardware- and software systems.

We have strong experience in measuring techniques, electronics, software design and chemistry, and essentially work in two areas:

- Development of various complete industrial control-, testing- and condition monitoring systems.

- Sales of a variety of industrial supplies, such as high performance control valves, pressure gauges and convoluted metal hoses.

|

Viscomat II

|

|

|

|

Viscomat II is based on ISO 5351

- Standard method to estimate the limiting viscosity number of pulp in a dilute cupriethylenediamine (CED) solution.

- Indicates the degree of polymerization of the cellulose and therefore gives a relative indication of the degree of degradation resulting from the pulping and/or bleaching process.

- Primarily applicable to CED-soluble samples of bleached chemical pulps, but can be applied to any kind of pulp that dissolves in CED solution.

- Routine analysis that is performed daily at many labs.

|

|

|

- Three individually operated glass viscometer tubes.

- Connected to vacuum source, balance, water bath and computer.

- Internal water circulation pump.

|

|

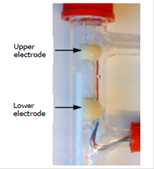

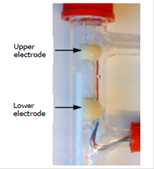

The glass viscometer tube |

|

- Three individually operated glass viscometers.

- Design complies fully with ISO 5351/SCAN-CM 15.

- Determines the efflux time for the pulp/CED solution via two electrodes that detects the liquid level.

- Temperature control via a mantle that is connected to external water bath (25°C).

- Connected to vacuum through a sample valve above the viscometer.

- Reliable design proven for > 25 years.

|

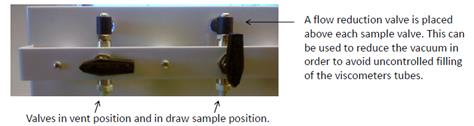

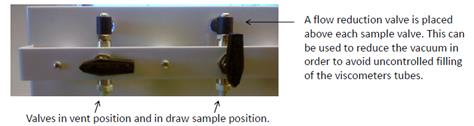

The sample valves |

|

The sample valves can be set in two positions:

- Vent position: the interior of the viscometer is open to air, letting the sample out through the capillary.

- Draw sample position: the interior of the viscometer is open to the attached vacuum, drawing the sample into the viscometer.

|

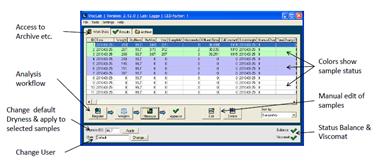

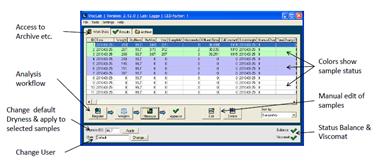

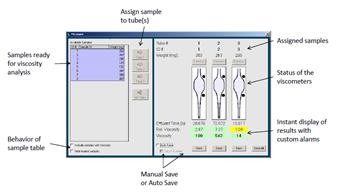

ViscLab – Main window |

| ViscLab 2 is the software used for controlling the Viscomat and analysis of data |

|

|

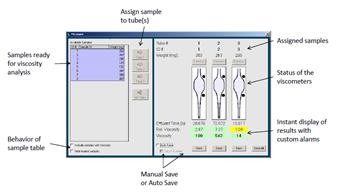

ViscLab – Measure Viscosity window

|

|

|

|

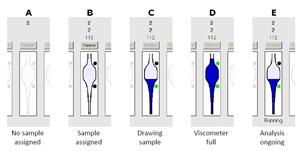

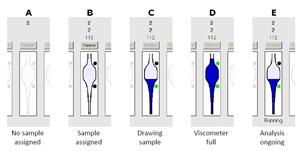

ViscLab – Status of viscometer tubes

|

|

The visual cues are complemented by audio beeps

|

| |

|

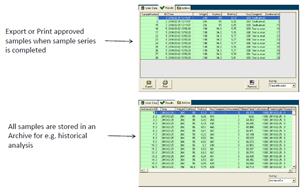

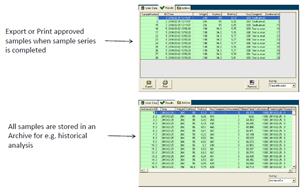

ViscLab – Results and Archive

|

|

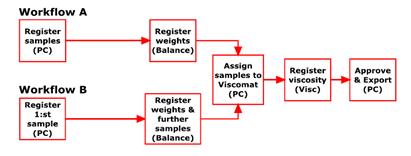

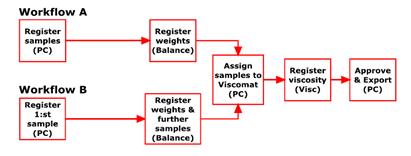

Workflow Viscomat II |

| Different workflows are implemented to support varying customer requirements

|

|

|

Assessories

|

| Balance

The Viscomat and the ViscLab software is designed to work with a balance connected to the system.

The standard balance we supply for the Viscomat is a Sartorius ED124S. This is a modern, fast, and robust balance with RS232 serial interface, internal calibration, 0.1 mg resolution and up to 120 g capacity.

|

|

| Water bath

A water bath capable of holding 25±0.1°C is required for the Viscomat. The water baths are delivered complete with a thermostat unit and a water bath container.

Our standard thermostat unit is the SC 100 from Thermo Scientific. This thermostat is designed for ease-of-use and energy efficiency. It has powerful pumping and heating capacity for closed loop applications such as in the Viscomat application, and is an economical choice offering solid performance for applications ranging from -28°C to +150°C. Our standard thermostat unit is the SC 100 from Thermo Scientific. This thermostat is designed for ease-of-use and energy efficiency. It has powerful pumping and heating capacity for closed loop applications such as in the Viscomat application, and is an economical choice offering solid performance for applications ranging from -28°C to +150°C.

The water bath container is selected based on the the cooling requirements and the number of samples to fit into the bath. The non-refrigerated water baths are shipped with a tap water cooling coil, since the 25°C required by the viscosity method usually is close to the ambient room temperature.

A set of preselected configurations are shown below:

|

SC100-S15: Temperature range +20°C – 100°C with tap water cooling, complete with external circulation for connection to the Viscomat II and tap water cooling coil. Capacity: 11-20 liters. Material: stainless steel.

Order #: LV0021 |

| |

|

|

SC100-S21P: Temperature range +20°C – 100°C with tap water cooling , complete with external circulation for connection to the Viscomat II and tap water cooling coil. Capacity: 13-21 liters. Material: Polyphenylene Oxide (PPO).

Order #: LV0018 |

| |

|

|

SC100-A10: Temperature range -10°C – +100°C, complete with external circulation for connection to the Viscomat II. Capacity: 5 liters. Material: stainless steel. This is a refrigerated bath which means that it can keep the temperature on 25 without requiring tap water cooling coil.

Order #: LV0017 |

| |

|

|

All water baths can be delivered with a lifting platform for holding the sample bottles in place. Please contact us for more information.

For more details, additional configurations and add-ons, download the pdf brochure. |

|

|

|

|

| Water-jet vacuum pump

The water-jet pump is used for generating the vacuum required to pull the samples up into the viscometer tubes.

|

- The pump is connected to an ordinary water tap, preferentially with at least 3 bar pressure.

- Overall length: approx. 210 mm (R 3/4“ connector fitted)

- Weight: approx. 33 g (R 3/4“ connector fitted)

- High chemical resistance, fluid path consists of PP, FKM and PTFE.

- Operating temperature up to max. 80 C°.

Features:

- Integrated non-return valve increases safety.

- Simple operation and easy to clean.

- Detachable vacuum connection.

- Very low water consumption: The flow configuration has been optimized, resulting in a 33% reduction of water consumption (190 liters/h at 3.5 bar water supply pressure).

- Constant ultimate pressure: The ultimate pressure of 16 mbar (water temperature: 12 °C) is reached across a wide range of water supply pressures (from 3 to 6 bar).

- High suction capacity: Flow rate of approx. 400 litres/h of air (against atmospheric pressure, at a water supply pressure of 3.5 bar at 12 °C water temperature).

|

Included:

Water connection sleeve nut R 3/4“, reducing adapter R 1/2“, and tubing connector (hose nozzle) of 10-12 mm outer-Ø. |

Our standard thermostat unit is the SC 100 from Thermo Scientific. This thermostat is designed for ease-of-use and energy efficiency. It has powerful pumping and heating capacity for closed loop applications such as in the Viscomat application, and is an economical choice offering solid performance for applications ranging from -28°C to +150°C.

Our standard thermostat unit is the SC 100 from Thermo Scientific. This thermostat is designed for ease-of-use and energy efficiency. It has powerful pumping and heating capacity for closed loop applications such as in the Viscomat application, and is an economical choice offering solid performance for applications ranging from -28°C to +150°C.