ผู้ผลิตเครื่องมือทดสอบถังปฏิกรณ์ความดันสูงสำหรับงานวิจัยและพัฒนาผลิตภัณฑ์ทางด้านวิทยาศาสตร์ วิศวะเคมี ปิโตรเลียม ปิโตรเคมี พลาสติค โพลีเมอร์ อุตสาหกรรมยาและเครื่องสำอาง อุตสาหกรรมอาหาร เช่น ถังสกัดสารความดันสูง (High Pressure Reactor) ปั๊มของเหลวแรงดันสูง อุปกรณ์วาล์วและท่อความดันสูง (High Pressure Valve & Tubing) เครื่องสกัดสารแบบท่อ (Tubular Reactor System) เครื่องสกัดสารสำคัญด้วยคาร์บอนไดออกไซด์แบบยิ่งยวด (Supercritical Fluid Extraction : SFE-CO2 ), เครื่องสกัดสารด้วยน้ำแบบยิ่งยวด (Supercritical Fluid Extraction : SFE-H2O) การทำลาย-ฆ่าเชื้อผลิตภัณฑ์อาหารด้วยความดันสูง (CIP&FIP) การทำผงผลิตภัณฑ์ยาและเครื่องสำอาง (SFE-SAS) การทำครีมผลิตภัณฑ์ยาและเครื่องสำอาง (SFE-RESS) เครื่องสกัดสารอนินทรีย์จากพลาสติคด้วยความดันสูง (High Pressure Reactor) เครื่องศึกษาประสิทธิภาพของตัวเร่งปฏิกิริยา (Catalyst Reactor) เป็นต้น

– Tubular Oven Type Catatest Reactor

– High Pressure Stirring Reactor (Glass / Metal)

– pH Controlled Reactor System with Stirring

– Supercritical Water Oxidation System (SCWO)

– Supercritical Fluid Dryer (SFD)

– Oven Type Supercritical Fluid Extraction (SFE)

– Cold Isostatic Pressure Reactor System (CIP)

– Food Isostatic Pressure Reactor System (FIP)

ตัวอย่างการใช้งาน (Applications)

Polymerization, Hydrogenation, Dehydrogenation, Oxidation, Amination, Distillation, Organic Synthesis, Catalytic Reaction, Isomerization, Poly-Silicon CVD, Poly-Silicon FBR, Bio- Polymerization, Gasification, Fuel Cell, Supercritical Extraction, Subcritical Extraction, Catalytic Combustor, GTL Process, CTL process, Coal Slag Tester, CO2 Dry & Cleaning, DME Process, etc.

R-201 Series Reactor System R-201 Series Reactor System |

|

General Specifications General Specifications |

| – The vessel of R-201 Series Reactor is metal. – General Max. Pressure : 414 Bar (6000 psig) – General Max. Temperature : 500℃ – General Capacity: 100ml~500L – R-201 & 211 Series Reactors are designed to select between the metal vessel & glass vessel. And these are designed to move vessel by pressure cylinder easily. |

Order Guide Order Guide |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

R-211 Series Glass Reactor System R-211 Series Glass Reactor System |

|

General Specifications General Specifications |

| – The vessel of R-211 Series Glass Reactor is glass. – General Max. Pressure : 14 Bar (220 psig) – General Max. Temperature : -30~250℃ – Capacity: 100ml~100L – R-201 & 211 Series Reactors are designed to select between the metal vessel & glass vessel. And these are designed to move vessel by pressure cylinder easily. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R-202 Series Oven type Reactor System |

|

Features Features |

| Easy to make temperature uniform without effect on Easy to open & close the cover from the vessel because of pin Easy to move the vessel by lifting in the oven |

General Specification General Specification |

|||||||||

|

Order Guide Order Guide |

|||||||||||||||||||||

* Please select above numbers. ex) C①M②P①T①V① |

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

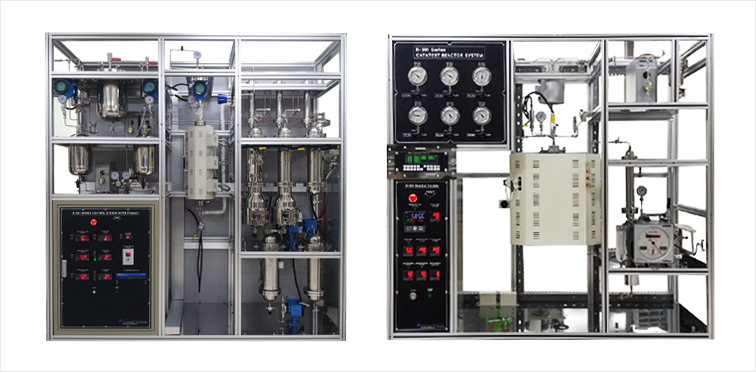

| R-301 Series Catatest Reactor System |

|

Use of catatest Use of catatest |

| – Determinations of different variables for researching on Catalyst improvement, such as; Reacting Temperature, Pressure and Feed Flow, reaction temperature, Pressure, Feed flow, reaction kinetics, etc – Test of Catalyst on Hydrogen reaction – Catalyst Screen, Selectivity & Activity Test – Test of Catalyst Life Span |

General Specification General Specification |

| – Catalyst volume (5mL~2L) : 316SS & Hastelloy C276 – Reactor Design Pressure : 1,000psig~6,000psig – Reactor Design Temperature : 800℃ – Operating Temperature : 650℃ – Operating Pressure : 1200psig – Liquide Flow rang : 20mL/min~100L/min – Gas flow range: ⇒ H2 gas : 50mL/min~3L/min ⇒ O2 gas : 50mL/min~3L/min ⇒ N2 gas : 50mL/min~500mL/min ⇒ Feed&Spare gas : 50mL/min~500mL/min |

Order Guide Order Guide |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

| R-302 Series Compact Catatest Reactor System |

|

Features Features |

| Compact design of the complete system for easy installation and also easy transport by wheel. |

Oventype Skid Oventype Skid |

| Oven system surround reaction zone can keep the even test without any effect from any change of circumstance. Also, it can of reactor can keep even temperature of oven circumstance. |

General Specification General Specification |

||||||||||

|

Order Guide Order Guide |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

| R-401 Series Supercritical Fluid Extraction System & SCWO |

|

Features Features |

| – SFE&SCWO can be selected according to its purpose lf use – Supercritical Fluid Extractions and Reaction’ Capacity, Pressure. Temperature, etc, are all optional selections available – As for Capacity, it is standard from 20mL up to 2L, and when it should be an optional selections available. – Designing is available from 20mL up to 500mL for 10,000psig, 5,000psig when 1Liter and 2Liters. |

General Specification General Specification |

| – Capacity : 50mL~10L – Design Pressure : 10,000psig – Design Temperature : 0~500℃ – Materials : 316SS, Hastelloy C-276 – Heater Capacity : 0.5~5Kw – Support Stand : Floor Stand – “K”Type Thermocouple & Thermowell – Pressure Gauge & Pressure Transmiter (0~10,000psig) |

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

| R-401 Series Supercritical Fluid Extraction System & SCWO |

|

Features Features |

| – SFE&SCWO can be selected according to its purpose lf use – Supercritical Fluid Extractions and Reaction’ Capacity, Pressure. Temperature, etc, are all optional selections available – As for Capacity, it is standard from 20mL up to 2L, and when it should be an optional selections available. – Designing is available from 20mL up to 500mL for 10,000psig, 5,000psig when 1Liter and 2Liters. |

General Specification General Specification |

| – Capacity : 50mL~10L – Design Pressure : 10,000psig – Design Temperature : 0~500℃ – Materials : 316SS, Hastelloy C-276 – Heater Capacity : 0.5~5Kw – Support Stand : Floor Stand – “K”Type Thermocouple & Thermowell – Pressure Gauge & Pressure Transmiter (0~10,000psig) |

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

| R-402 Compact Supercritical Fluid Extractor System |

|

Features Features |

| – Without the effect on surrounding temperature users can make the temperature uniform. – Users can gain the extract from the extractor more easily than system. – Users can open & close the cover from the vessel because of pin type. – Users can move the extractor by lifing in the oven easily. |

General Specification General Specification |

|||||||||||||||

|

Order Guide Order Guide |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

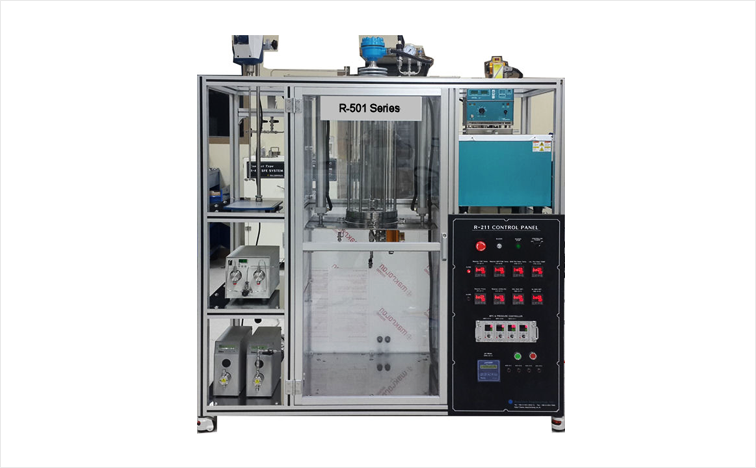

| R-501 Series the Automation System |

|

Features Features |

| – Temperature monitoring & PID control – Pressure monitoring – Pressure Control(option) – Agitating Speed Monitoring & PID Control – pH Monitoring – ISE Monitoring(Options) – pH Control(Options) – Conductivity Monitoring(Options) – DO Monitoring(Options) – COD Monitoring(Options) – ORP Monitoring(Options) – Safety : Overtemp & Overpressure monitoring & Shutoff function – Programmable Temperature Control(Options) – R-SCS S/W – Wave Form Chart : Auto Scale Date (Time vs. Scope, Sweep Chart), Format & precision Control Mapping mode (Linear or log axis), Zoom in Rectangular – Elapsed Time (HH:MM:SS) : Shows Entire Elapsed time. – Reaction Time (HH:MM:SS) : Shwos Date Saving. – Support Korean version of File Name. – Saving Data with ASCII Format |

Please contact to us for other temperature, pressure and capacity besides above standard specification. Please contact to us for other temperature, pressure and capacity besides above standard specification. |

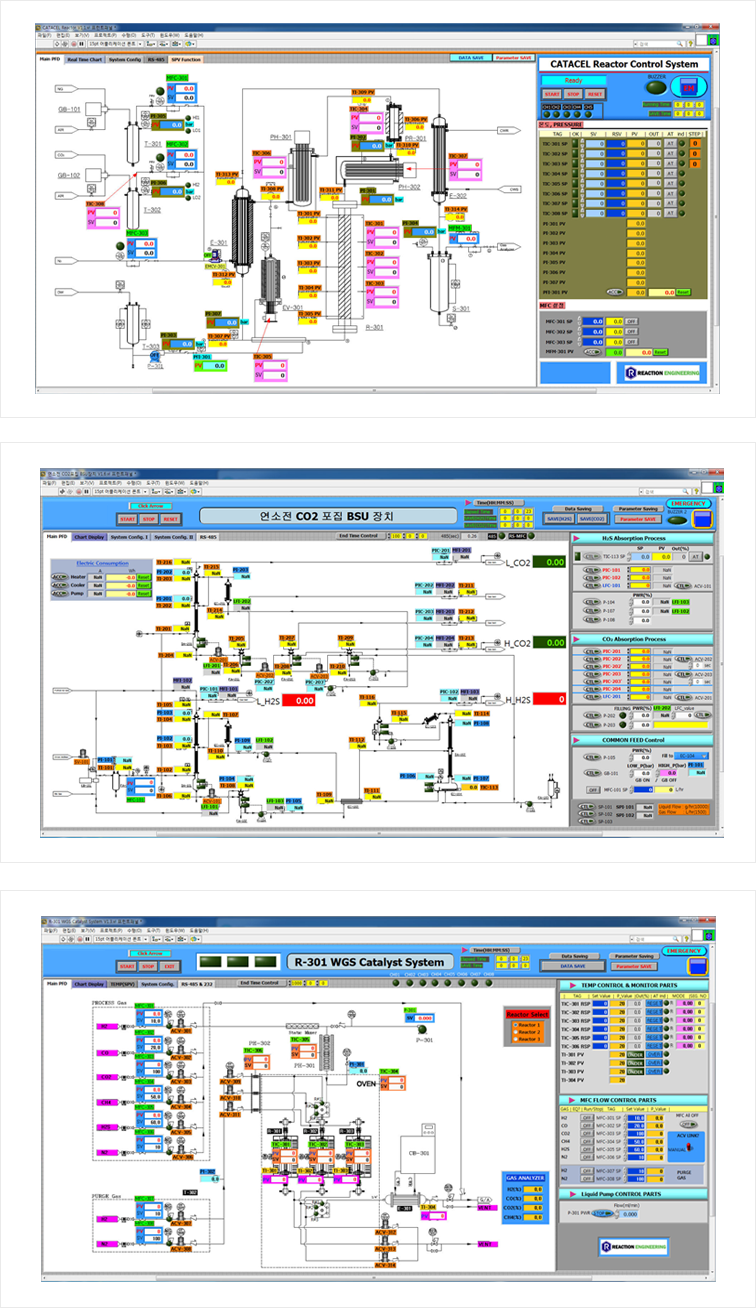

| Software Program |

|

All systems can be remotely controlled by the Software Program. All systems can be remotely controlled by the Software Program. |

Pressure Vessel

Pressure Vessel