ผู้ผลิตเครื่องมือทดสอบและวิจัยทางด้านการรับรองมาตรฐานความปลอดภัยของผลิตภัณฑ์ (Process Safety Instruments) เช่น Auto Ignition Temperature, Dust Explosion, Gas and Vapour Flammability, Oxidising Liquid Test, Electrical Resistivity และ Electrostatic Testing

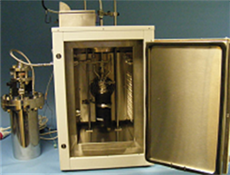

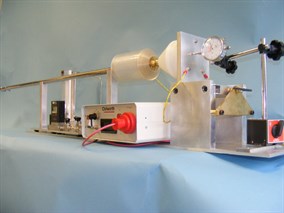

CTL01 10g Screening Tool

Functional Specification and Deliverables:

- Carius oven – 110-240 V a.c /1 kW oven

- Temperature controller and oven range 0 – 400 °C (ramp typical 0.5 °C)

- Temperature accuracy within + / – 1 °C

- Pressure range 0-100 barg. ¼” transducer connected via 1/16″ oil filled pressure link

- Pressure accuracy within + / – 0.1 barg from 0-50 barg and within + / – 0.2 barg above 50 barg

- Data logging – slow log rate – every 30 sec, fast log rate – every 0.1 sec standard

- Carius system program and driver discs

- Miscellaneous cables

- Set of Carius glass tubes and miscellaneous fittings supplied as standard

- Traceable calibration (master equipment – UKAS calibrated)

- Tested with known calibration sample prior to delivery

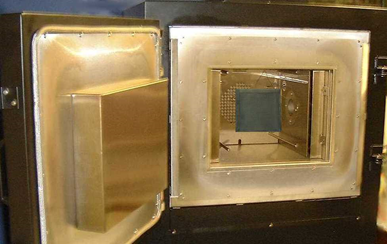

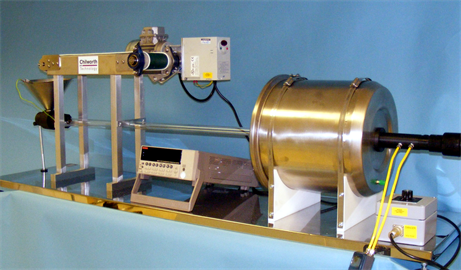

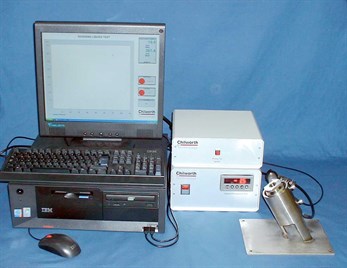

CTL02 Adiabatic Dewar Calorimeter ADC II

Above: an Adiabatic Dewar Calorimeter (shown with electronic control unit & optional tempering cell for venting trials)

Above: the containment enclosure which Chilworth can also supply as an option

Functional Specification and Deliverables:

- 6 kW 3-phase 380 V – 415 V Dewar oven. 0 – 400 °C capability

- Pressure range 0 – 100 barg. Vent relief set to 23 barg

- Dewar flask set with two fully ported and populated stainless steel head assemblies (ports include potential for entry of sample thermocouple, sample pressure sensor, sample heater, stirrer motor, additional spare thermocouple)

- Electronic control unit (configured to suit various test scenarios in conjunction with the supplied software) – with built in oven temperature controller (oven temperature tracks the sample temperature reliably within 1 °C or better under steady rate of rise conditions and can follow exothermic activity of sample at rates of up to 40 – 60 °C / min). Also features sample pressure and heater power local monitors, emergency manual vent for the vessel and interfacing to all ancillary Dewar services e.g system sensors and optional extras highlighted below

- Personal computer and LCD monitor with ADC software pre-installed

- Data acquisition card capable of monitoring and / or controlling: sample temperature, oven temperature, sample pressure, stirrer speed, stirrer torque, heater power and also optional extras such as Tempering cell pressure, tempering cell inlet and outlet solenoid operation, additional thermo-couples, Chemical injection pump, laboratory balance, Gas Burette. Typical log rates are: every 20 seconds for stan dard logging and every 0.1 second logging per channel based on the trigger point being exceeded on rate of pressure or temperature rise data

- Accuracy of pressure + / – 0.1 barg to 50 barg and + / – 0.2 barg above 50 barg

- Accuracy of temperature + / -1 °C

- 1 x instruction manual

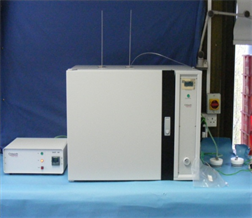

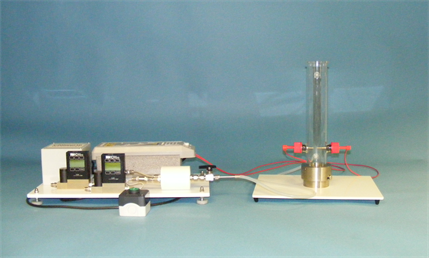

CTL03 Gas Burette System

Above: Gas Burette apparatus Current design with U-tube mounting board

Functional Specification and Deliverables:

- Mains supply: 110 – 240 V a.c

- Accurate data up to approximately 5 cm3.S-1

- Analogue count output and analogue pressure output (1 V or 10 V full scale selectable)

- Compatible with the data acquisition system of a Mettler RC1 system or any other data acquisition system

- Supplied with electronic control unit, mounting back-board, Gas Burette U-Tube, solenoid outlet valve, pressure transducer, silicon oil, glass accessories, miscellaneous tubing and cables,100 ml glass calibration syringe

- 1 x instruction manual

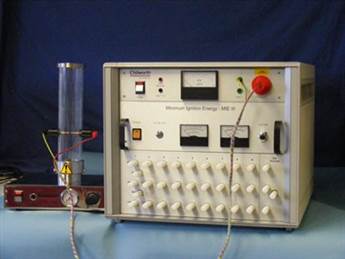

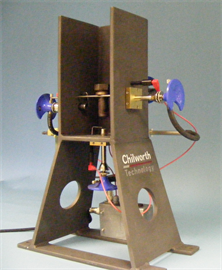

CTL04 MIE III Cloud Apparatus

Functional Specification and deliverables:

- Mains Supply – Volts / Amps: 110 – 240 V a.c / 3 A

- Energy Range: 4 mJ – 2000 mJ

- 29 device capacitance bank (energy selection increments of 1 mJ)

- 0 – 15 kV adjustable high voltage power supply

- Arc gap breakdown voltage monitoring unit utilising JCI 140 internal proximity voltmeter

- Chart recorder breakdown strength monitoring software plus data-card for use with PC data acquisition package which is supplied as standard (for use with a floating laptop – not supplied)

- Dust / air dispersion unit with set of acrylic Hartmann tubes with adjustable air regulator facility and rear external air inlet connection

- Niacinamide calibration sample (with known calibration data)

- 1 x instruction manual

CTL05 MIT Cloud Apparatus

Functional Specification and deliverables:

- Mains supply: 100 – 120 V or 220 – 240 V operation

- 1 kW furnace heating from ambient to 1000 °C via temperature control unit

- Supplied with spare glass sealing gaskets and observation glasses, set of thermocouples, new integral control unit complete with furnace temperature controller and inlet pressure meter

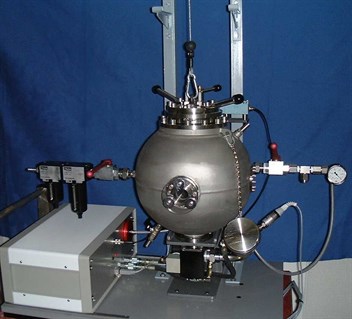

CTL06 20 Litre Sphere Test Apparatus

20 litre sphere test apparatus with optional lifting gear shown

Functional Specification and Deliverables:

- Mains supply: 110 – 240 V a.c operation

- 20 litre sphere for dust explosion testing

- Data control unit – interfaces with measurement piezoelectric sensors via charge amplifiers and sends pressure and control data to / from PC

- Ignitor initiation unit – sends ignite signal to chemical ignitors and also filters the air and contains air inlet lines

- Set of spare parts

- 1 x instruction manual

CTL07 Portable Explosion Kit

Functional Specification & Deliverables:

- Powder dispersion unit with acrylic Hartmann tube

- Mains supply: 110 – 120 V / 220 – 240 V a.c – 200 W

- 8.5 kV / 0.25 mA constant arc internal ignition source

- Hand-held control handset for arc activation and air dispersion

- Double action hand pump for pre-charging the internal air reservoir

- Rupture paper disc set

- Air line

- Electrodes

- Built in air regulator – typical default setting 4 barg

- Lightweight at just 10 kg and packed into robust case

- 1 x instruction manual

CTL08 Group A/B Flammability Screening Lab

Group AB Flammability Screening Laboratory Rig

Functional Specification & Deliverables:

- Mains supply: 110 – 240 V a.c / 3 A

- Dust / air dispersion base complete with steel mushroom for dust cloud optimisation – typically 7 barg service air required

- 1 litre acrylic Hartmann Tube (can be cleaned with warm soapy water and dried)

- Tube rupture papers (for top tube closure)

- Brass electrodes for creating arc

- Constant arc power source (10 kV)

- Remote handset (arc and air activation)

- 1 x instruction manual

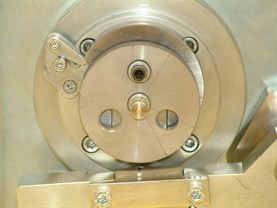

CTL09 Hartmann Pressure Tube Apparatus

Hartmann Pressure Tube Apparatus

Functional Specification & Deliverables:

- Mains supply: Volts 110 – 240 V a.c / 3 A

- Dust / air dispersion base with mushroom design to optimise internal dust cloud

- 1.2 litre stainless steel Hartmann Tube

- Top removable screw cap with built-in dynamic pressure transducer and vent valve

- Viewing window (for visual observation of arc gap and flame propagation)

- Brass Electrodes

- Constant arc power source (10 kV)

- Remote handset (arc & air activation)

- PC / LCD monitor with control and acquisition software included

- Electronic control unit containing high speed data acquisition card and pressure transducer charge amplifiers

- O’ring set

- High speed pressure transducer

- 1 x instruction manual

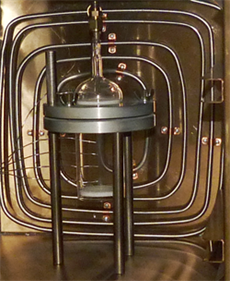

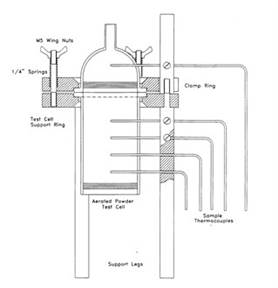

CTL12-13 Aerated & Diffusion Cell Screening Apparatus

Figure 1: Aerated cell with pre-heated air (top entry) Figure 2: Powder aerated cell set-up

Functional Specification & Deliverables:

- Mains supply: Volts 220 V – 240 V a.c / 7 A or 120 V a.c / 13 A

- 30 litre fan assisted oven (400 °C capability)

- Air flow meter fitted (adjusts flow through the pre-heating coil). Typical air flow is set to 0.6 l.min-1

- Temperature controller (ramps oven at 0.5 °C.min-1)

- Glass test vessel set each comprising cylinder closed at the base and top with sintered glass and a close fitting lid for aeration cell tests

- Thermocouples for monitoring oven temperature at several places within the powder layer within the vessel (see figure 2)

- Data acquisition software program (pre-installation on optional PC recommended) for conducting either the aerated cell test (with lid) or the diffusion cell test (no lid)

- Thermocouple extension cables

- Glass vessel support stand with pre-drilled thermocouple securing holes for repeatable alignment of thermocouples

- 1 x instruction manual

CTL14 Basket Test Apparatus

Functional Specification & Deliverables:

- Oven: 0 – 400 °C fan assisted with PID temperature controller

- Mains supply: 220 – 240 V single phase / 7 A or 120 V single phase / 13 A

- Thermocouples: K type, 1 metre long. Oven and sample

- Reaction vessels: 1 set stainless steel mesh basket cubes 50 mm / 75 mm / 100 mm* (more can be supplied as spares) – 0.053 mm opening

- Sample support: Outer spot welded basket which permits air flow circulation to / around inner basket cubes

- Miscellaneous items: Manuals, catchment tray

- Data acquisition card & software: Basket test apparatus data acquisition software which can be pre-installed on the recommended optional PC / monitor

CTL15 Layer Ignition Temperature Apparatus

Functional Specification & Deliverables:

- Layer Ignition Hotplate (1250 W / 6 A, 220 – 240 V (100 – 120 V via transformer option) single- phase. Temperature range = 0 – 400 °C

- Remote controller unit (incorporates PID temperature control). Sample may be ramped in temperature or held isothermally

- K-type thermocouple and extension cable for both hotplate and sample

- 5 mm, 12.5 mm, 15 mm sample retaining rings supplied (100 mm diameter)

- Data acquisition hardware and software

- Acrylic sealing compound.

CTL16 Flammability of Solids – Burning Rate Apparatus (UN Test)

Functional Specification & Deliverables:

- Fire Train forming mould with anodised aluminium 90° Vee groove former, support cradle, base plate and brass holding clamps

- Test Plate. Impervious, non-combustible and low thermal conductivity quartz testplate

- An ignition source is required but is not supplied due to the documentation and certification required to ship a gas cylinder overseas. A small portable hand held butane or propane cylinder with a nozzle diameter of greater than 5mm is all that is required

- Metric rule for measuring Fire Train distances

- High grade non-rusting steel rule marked in millimetres complete with UKAS calibration certificate

- Laboratory stopwatch for timing combustion and linear burning intervals

CTL17 Oxidising Solids Test Apparatus

Oxidising Solids Test Apparatus

Functional Specification & Deliverables:

- Mains supply: 220 – 240 V mains inlet / 12 V d.c output 150 W hot coil power source

- 1 x glass conical sample loading chamber (glass blown with 60° angle for optimal powder cone as per test standard requirements)

- 1 x insulated quartz plate

- 1 x roll 100 m NiCr wire (0.5 mm diameter)

- 1 x stop watch

- 1 x instruction manual

CTL19 Auto Ignition Test Apparatus (AIT)

Functional Specification & Deliverables:

The ASTM Method spec is covered here. For DIN standard apparatus deliverables please contact us.

- Mains supply: 220 – 240 V 50 Hz single phase furnace (other voltages are available)

- 150 – 650 °C (standard operating range)

- Capable of controlling the flask temperature within + / – 1 °C up to 350 °C and + / – 2 °C from 350 °C to 650 °C

- Temperature uniformity is better than + / – 4 °C measured on the outside of an aluminium clad flask at three positions

- 10 x round bottom borosilicate flasks

- Data acquisition hardware and AIT software supplied

- Supplied with vapour temperature thermocouple, spare thermocouple and sample injection syringe set

- Pre-calibrated

- 1 x instruction manual

CTL20 Flammable Range Test Apparatus

Flammable Range (LFL/UFL) Apparatus

Functional Specification & Deliverables:

- Flammable range fan assisted oven 220 – 240 V a.c typically 1.5 kW / 7 A (110-120 V a.c versions are possible)

- Temperature rating 0 – 300 °C (test operating temperature limited to 150 °C due to the PTFE head assembly)

- Safety glass window in door

- Magnetic stirrer drive

- New integral oven controller including pressure reader, temperature reader and oven controller. Also includes stirrer controller and arc controller ignition source and activation handset

- 1ml, 3 ml, 5 ml and 10 ml disposable syringe sets supplied to get you started

- 500 µl syringe with needle

- 5 litre glass test vessel

- 1 x vacuum pump + 6mm inlet line & exhaust hose

- Vacuum pump inlet filters, plastic-coated magnetic stirring bars

- 1 x remote handset for constant arc activation

- 2 x 5 litre covers /head assemblies with ports for sample injection, electrodes, thermocouple, vacuum / exhaust line(s) with needle valve isolation and transducer connection (complete with cover clamps)

- 1 x pressure transducer -1 to 1 barg

- 1 set x 5 litre head rubber seal gaskets

- 1 set x septums for injection line connection

- 1 x length of tungsten constant arc electrode wire

- 1 x T-Piece fitting

- 1 x 5 litre vessel support stand

- 1 x 5 litre vessel stirrer extension rod

- 2 x mains supply leads

- Comprehensive English instruction manual complete with pressure and temperature calibration and monitor manuals

CTL22 BAM Fallhammer Test Apparatus

Flammable Range (LFL/UFL) Apparatus

Functional Specification & Deliverables:

- A solid cast steel base block

- Main 100 mm diameter anvil

- A centring ring for locating the intermediate anvil on the main anvil

- 2 x Intermediate 26 mm diameter anvils

- 2 x locating rings with orifices for gas release

- 200 steel cylinders (roller bearings)

- 50 rubber o’rings for steel cylinders (liquid testing only)

- 100 steel collars for steel cylinders locating

- An upper to lower cylinder distance gauge for 1 – 2 mm sample gap required for liquids

- A central column with guides (graduated scale) ready set for correct height

- A 1 kg drop weight carrier assembly

- A 1 kg weight already fitted to 1 kg drop weight assembly for a 2 kg overall weight

- A 5 kg drop weight carrier assembly

- A 5 kg weight already fitted to 5 kg drop weight assembly for a 10 kg overall weight

- A drop weight electromagnetic release device

- An electromagnetic power supply distribution box together with electroma gnet 12 V supply cable, 100 – 120 V, 220 – 240 V mains inlet supply cable and remote handset for weight release

- Electromagnet safety pin

- A 40 mm3 sample loading spatula

- A polycarbonate protective shield

- 1 x instruction manual

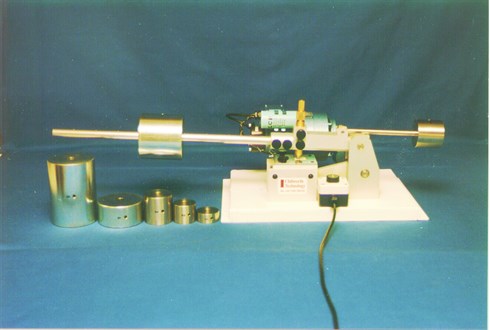

CTL23 BAM Friction Test Apparatus

Functional Specification & Deliverables:

The apparatus and accessories supplied are as follows:

- 1 x Friction Tester assembly complete with base plate, cam assembly with sliding carriage, motor drive ( 220 / 240 V / 50 Hz or 100 / 120 V 60 Hz), peg locating device, counterbalance arm and operating switch box

- 1 x loading arm with 9 notches for weight location

- 1 set (400 pce) porcelain pegs

- 1 set (100 pce) porcelain plates

- 1 x 0.28 kg load weight (Weight 1)

- 1 x 0.56 kg load weight (Weight 2)

- 1 x 1.40 kg load weight (Weight 3)

- 1 x 2.79 kg load weight (Weight 4)

- 1 x 5.58 kg load weight (Weight 5)

- 1 x 8.34 kg load weight (Weight 6)

- The weights above allow coverage of the desired 5 – 360 N load range

- 1 x counterbalance weight

- 1 x instruction manual

- 1 set calibration graphs for load weight locations

- All apparatus supplied by Chilworth is provided with a warranty (excluding consumables)

CTL24 Koenen Tube Test Apparatus

Functional Specification & Deliverables:

The apparatus and accessories supplied are as follows:

- Support frame with 4 burners and solenoid valve (Propane Gas inlet)

- Complete set of Orifice plates comprising of the following sizes: 1, 1.5, 2, 2.5, 3,3.5 ,4,5 ,6 ,8 ,10 ,12 ,14 ,16 ,18 & 20 mm

- Collar assembly including 2 sizes

- 100 disposable Koenen tube shells

- Length of gas inlet hose

- Remote handset for gas inlet valve and ignitor activation

- 4 x electrical ignitor fitted and 8 x spares

- Koenen tube support rod spares x 2

- Spare Teclu burner set (4 total)

- 1 x 1 mm diameter k-type thermocouple + thermocouple extension cable

- Data acquisition card / program for monitoring heat-up during initial burner set-up

- Stopwatch

CTL25 Time / Pressure Apparatus

Time / Pressure Test Apparatus

Functional Specification & Deliverables:

- PC – current up-to-date specification (it is recommen ded that this is supplied as standard)

- LCD monitor

- Time Pressure Control Unit with push button initiation of logging of data and ignition system

- Time Pressure – pressure monitor and ignition power supply unit 220 – 240 V / 10 A

- Time Pressure Vessel and stand

- Pressure Transducer (0 – 25 barg / 0 – 362.5 Psig)

- Igniter output cable

- Data communication cable

- Spanner for vessel end cap maintenance

- 1 set Aluminium burst disks (100 pcs)

- 1 set Lead washers (200 pcs)

- Time pressure documentation

- Time pressure software program

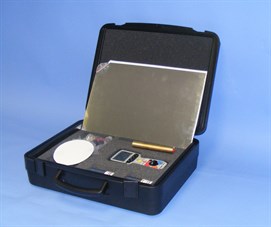

CTL26 Floor Glove & Footwear Kit

Floor, Glove and Footwear Test Kit (static measuring options available)

Functional Specification & Deliverables:

- Resistance meter – Maximum range > 200 G? (UKAS Calibration Certificate supplied)

- Brass hand electrode with pre-fitted 10 K? safety resistor installed 25 mm diameter x 160 mm

- 2 x stainless floor electrodes with conductive rubber pads, each 63.5 mm dia x 105 mm = 2.5 Kg

- PTFE backing sheet – 300 mm x 470 mm x 3 mm

- Aluminium floor plate – 300 mm x 470mm x 2.5 mm

- 1G? calibration check resistor

- 5 metre earth lead

- Miscellaneous other leads (for resistance meter)

- Instruction manual

CTL27 Liquid Conductivity Test Apparatus

Liquid Conductivity Test Apparatus

Functional Specification & Deliverables:

- 10 V d.c power supply (resolution 0.1 V, accuracy + / – 2 %)

- Picoammeter (2 nA to 20 mA ranges) – 2 nA range has 10 fA resolution + / – 400 fA. Noise 20 fA. (Manufacturer’s calibration certificate supplied)

- Custom manufactured liquid conductivity test cell

- Miscellaneous.cables (transorb in-line overvoltage protection unit – protects sensitive measuring equipment from over voltage

- Instruction manual

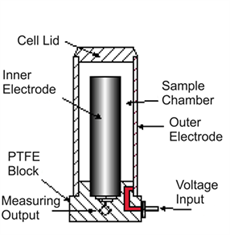

CTL28 Powder Resistivity Test Apparatus

Powder Resistivity Test Apparatus

Functional Specification & Deliverables:

- Custom manufactured power supply with 500 V, 1 kV, 2 kV, 3 kV (fixed settings) and 0 – 10 kV (adjustable settings for other uses requiring higher voltages)

- Accuracy + / -1 V on 500 V range, + / – 10 V (all other fixed settings), within + / – 100 V with 10 kV applied on the 0 – 10 kV adjustable range. Maximum current draw from power supply 500 µA

- Minimum resistance measurement possible is approximately 1 – 2 M? (resistivity ca 400 k?.m) – dependent on sample properties and power supply voltage output tolerances

- Custom manufactured test cell with guard ring electrode incorporated

- Picoammeter for measurement of current through or across the test sample (2 nA to 20 mA ranges) – 2 nA range has 10 fA resolution + / – 400 fA. Noise 20 fA. Manufacturer’s calibration certificate supplied

- Miscellaneous cables

- In-line Transorb over voltage protection unit (for protecting the sensitive pico-ammeter from over voltage)

- Powder resistivity apparatus instruction manual

CTL29 Protective Clothing Surface Resistivity Test Apparatus

Surface & Volume Resistivity Test Apparatus

Functional Specification & Deliverables:

- Terra Ohmeter spec

- BS EN1149 Protective Clothing Surface (volume resistivity test cell)

CTL30 Gas Probe Incendivity & Calibration Apparatus

Gas Probe Incendivity & Calibration Apparatus

Functional Specification & Deliverables:

- Gas probe with manual quick release gas shut-off valve and gas mixing shroud

- Gas mixing unit with 2 x gauges: one for air (rotometer) and one for gas (digital mass flow meter with pre- calibrated gases selectable in memory – default is Propane). Total gas flow to the gas probe must be 0.21 litres / sec + / – 0.04 litres / sec (ref: IEC 61340-4-4)

- A 10 kV custom manufactured calibrated power supply unit with fixed 500 V, 1 kV, 2 kV, 3 kV and adjustable 0 – 10 kV front panel controls. 220 – 240 V / 100 – 120 V a.c input 10 kV output (500 µA) LED display read-out of high voltage output

- A calibration document for the 10 kV power supply included (master calibration equipment UKAS calibrated)

- A capacitance charging unit with electrode

- Instruction manual

CTL32 Powder Chargeability Test Apparatus

Powder Chargeability Test Apparatus

Functional Specification & Deliverables:

- Custom made stainless steel Faraday cage and drum

- Supply of powder collection bags

- Electronic Manometer

- Electrometer

- Variable speed conveyor belt system (transit time of belt typically set to 30 S)

- 1 stainless steel, 1 glass, 1 polypropylene tube for powder transit

- Sets of leads for measurement apparatus

- Baseplate – chargeability components already pre-mounted for ease of installation

- Stainless steel funnel and support stand

- Stopwatch

- Inline orifice plate for system outlet – already fitted

- Test instruction manual detailing installation, commissioning, test procedure and routine maintenance

- Industrial vacuum suction device with Hepa filter installed

- Industrial vacuum suction device variable speed controller – already fitted

- Miscellaneous instruction manual for Electrometer (on cd), manometer and stopwatch

- Fittings for the drum inlet and outlet (already fitted)

CTL34 Five-Litre Sphere Flammability Apparatus

Functional Specification & Deliverables:

- 0-150 °C operation

- Custom fabricated stainless steel 5 litre spherical vessel (ported to accept pressure transducers). Hydro-tested to 42 bar. Complete with certificate of conformity, hydro-test certificates, test gauge calibration certificates, hydro- test procedure

- Explosion chamber head custom fabricated and ported for liquid injection, vacuum, exhaust, nitrogen inlet, thermocouple and pressure link

- Arc ignition source / high voltage output ignition source. Operated via remote push-button on control box once vaporisation of the liquid sample has occurred

- Pressure measurement system electronic timer circuit built in to charge amp enclosure control box to initiate charge amps following ignition

- Oven enclosure. Capacity: approx 60 litres

- Mains supply: 100 – 120 / 220 – 240 V single phase. Fan assisted with built in bottom stirrer

- PID temperature controller and digital pressure display

- Safety feature: Oven vent (N.B that testing should be conducted in a room facility with extraction)

- Pressure transducers – fast response 10 kHz

- Data acquisition – fast response data acquisition time resolution linked in to PC for accurate data logging

CTL38 Self Accelerating Decomposition (SADT) Test H4 Apparatus

Functional Specification & Deliverables:

- 0-150 °C temperature range (110 – 120 / 220 – 240 V a.c oven typically 1.5 kW)

- Efficient flask holder / stand with minimal thermal influence on test

- Custom made vessel plug / head – fast set-up

- Data acquisition system provides fast and early indication of any exothermic onset

- Debris collection fine wire mesh basket cage system – enables management and containment in the event of any flask breakages

- USB Connectivity (computer option available)

CTL39 10 kV Power Supply

Functional Specification & Deliverables:

- Voltage settings : 500 V, 1 kV, 2 kV, 3 kV fixed 0-10 kV adjustable

- Current output capability : 500 µA

- Mains input : 100 – 240 V a.c 1 A

- LCD display – Resolution : 10 V on 500, 1 kV, 2 kV, 3 kV ranges: 100 V on 0 – 10 kV adjustable range

(Above 3 kV)

CTL43 Dutch Pressure Vessel Test

Functional Specification & Deliverables:

- Custom Dutch Pressure Vessel – stainless steel, type AISI 316

- Teclu burner

- Orifice plates – complete set of 8 including: 1.0, 2.0, 3.5, 6.0, 9.0, 12.0,16.0, 24.0mm. Thickness 2.0mm + / – 0.2mm

- Aluminium bursting discs – set. Diameter 38mm. Rated Burst pressure 620 + / – 60 kPa at 22 °C

- Stopwatch

CTL44 Electric Spark Tester

Functional Specification & Deliverables:

- Electric Spark Tester: electrical control and ignition system mounted within 19″ rack

- Mains supply : 220 – 240 V a.c single phase power

- Set of polythene strips and high voltage electrodes supplied as standard

- Instruction manual

- Top vent which can be connected to room extraction

- Safety features: door interlock and electrode earthing

- Newly designed enclosure, latched side access panel to aid cleaning

CTL47 Rotary Friction Test Apparatus

Rotary Friction Test Apparatus

Functional Specification & Deliverables:

- Rotary Friction Tester complete with integral control system

- Power requirements: 220 – 240 V a.c single phase power supply

- Air requirements: clean air supply at 80 psi (standard clean / filtered compressed air supplies (a standard clean 7 barg standard compressed air pressure supply is acceptable regulated down to 80 psi)

- Set of grit blasted wheels and sample blocks to get started (see options)

- Sample grit blasting block

- 1 x instruction manua

CTL51 Sustained Combustibility Test Apparatus – UN Test

Sustained Combustibility Test Apparatus

Functional Specification & Deliverables:

- 1 x 1250 W hotplate (200 mm diameter) 220 – 240 V / 6 A

- 1 x remote control unit with integral PID temperature controller

- 1 x interface control cable (which interconnects the remote unit to the hotplate)

- 1 x thermocouple extension control cable

- 1 x sustained combustibility test cell (installed and fixed onto the hotplate)

- 1 x test cell temperature thermocouple (1/16″ pocket)

- 1 x handheld digital k-type thermocouple reader with UKAS calibration

- 1 x set miscellaneous cables

- 1 x stopwatch

- 1 x instruction manual

CTL52 Flammability of Gases Test A11 Screening Apparatus

Flammability of Gases Test Apparatus

Functional Specification & Deliverables:

- 1 x 15 kV constant arc power source

- 1 x gas flow meter base plate with ignition and timer control

- 1 x pair non return valve and pre-mixing chamber and isolation valve pre-fitted to gas flow meter base plate

- 2 x gas mass flow meters (gas flow meter digital pre-programmed gases)

- 1 x power adapter unit for gas flow meters

- 1 x set glass tube sealing membrane

- 1 x flexible gas tube

- 1x glass test tube (quick tube bayonet release mechanism fitted)

- 1 x instruction manual

CTL56 Burning Behaviour Test Apparatus – VDI Method

Burning Behaviour Test Apparatus

Functional Specification & Deliverables:

- 1 x platinum hot coil current control unit

- 1 x heater power handset (pre-wired into the control unit)

- 1 x insulating block

- 1 x glass tube

- 1 x 100 mm length of platinum wire

- 100 – 200 V / 220 – 240 V – 6 A input

- Fine coil output current control (optimum 29 to 31 A. Control derived from low voltage d.c output)

- 1 x instruction manual

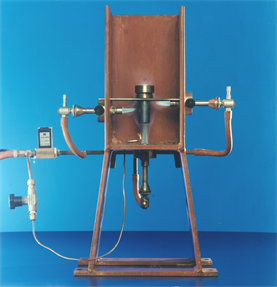

CTL57 Oxidising Liquids Test Apparatus

Oxidising Liquid Test Apparatus

Functional Specification & Deliverables:

- 1 x test vessel complete with integral pressure transducer side arm assembly, ignition electrodes / plug and burst disc mounting connection

- 1 set of 100 aluminium burst discs (consumable / spare parts)

- 1 x ignition power control unit with built in pressure monitor

- 1 x ignition control and acquisition unit (with integral data acquisition / control cards)

- Remote operation. Power supply with 10 A capability

- 1 x 100 m Nickel Chromium wire (consumable part)

- 200 x lead washers for sealing (consumable parts)

- 1 x pressure transducer : 0 – 362.5 psig range. Accuracy = within + / – 1 % of full scale reading

- 1 x side arm with vent valve for leak detection purposes (spare)

- Cables and miscellaneous connectors

- 1 x instruction manual

- 1 x PC (of current up to date specification, complete with oxidising liquids software pre-installed)

- 1 x LCD monitor

- 1 x oxidising liquids test programme