ผู้ผลิตเครื่องผสมสารนวัตรกรรมใหม่ (Kakuhunter) โดยใช้หลักการแรงปั่นเหวี่ยงหนีศูนย์กลาง (Planetary Centrifugal Mixer) ซึ่งหมุนในแนววงโคจร (Planetary) ผสมกับการหมุนของตัวอย่างในภาชนะแบบรอบตัวเอง (Rotation) ทำให้เกิดการผสมสารที่มีประสิทธิภาพสูง นอกจากนี้ยังสามารถไล่ก๊าซ (De-Gassing / De-Aerating) ออกจากตัวอย่างที่มีความหนืดสูงได้ภายในระยะเวลาอันสั้น เหมาะสำหรับตัวอย่างสารเคมี สี หมึก กาว เรซิน น้ำมัน ครีม เครื่องสำอาง ยา แว็กซ์ ไข จาระบี เซรามิกซ์ และการผสมสารที่อยู่ในรูปผง (Powder) เข้ากับของเหลว เป็นต้น

คลิ๊กด้านล่างเพื่อเลือกรุ่น Kakuhunter ที่เหมาะสม

- Kakuhunter / Planetary Centrifugal Mixer

- Vacuum Kakuhunter/ Planetary Centrifugal Mixer

- Entry Model Kakuhunter/ Planetary Centrifugal Mixer

- Exclusive Model Kakuhunter / Planetary Centrifugal Mixer

- Adopters

- Dispensing Machines

Kakuhunter/Planetary Centrifugal Mixer

Features common to standard models

- Advanced model equipped with the individual revolution and rotation speed control system

- Carry out mixing of various materials of low to high viscosity in a short time( tens of seconds to several minutes)

- Optimum settings enable user to achieve continuous operation. (5 steps)

- Revolution and rotation can be set individually, so various types of materials can be handled.

- There are no propellers and it does not need to clean the machine. In addition, there is no loss of materials.

กรุณาเลือกรุ่นตามขนาดบรรจุตัวอย่าง / Select by capacity:

Planetary Centrifugal Mixer SK-350TII

90 different revolution-rotation speed patterns are available by varying the ratio of

revolution and rotation.

A high function model for covering from research and development to small-scale

production.

400 ml × 2 cups compatible with various types of syringes

Planetary Centrifugal Mixer SK-1100

Model equipped for both

high speed revolution and a wide radius gyration, supporting for the production

of high quality materials.

The timing by which the revolving speed of rotation increases is controlled to

improve the mixing rate of powders and liquids and sustains the generation of

lumps.

1100ml × 2 cups

Planetary Centrifugal Mixer SK-2000T

- Maximum processing amount 2kg × 2 cups

- An order-made mixer compatible with the containers the client

currently uses. - Maximum compatible container size: 150 mm diameter x 170 mm

height - Multiple containers can be loaded by using an adopter, and loss

of material is reduced by selecting containers according to the production

amount. - It enables to have certain throughput without adopters.

2000ml × 2 cups (2kg)

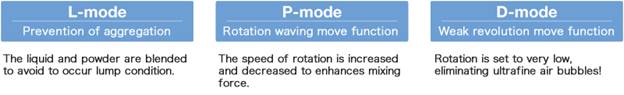

In addition to the normal mode, special modes suited for different materials can be selected

Planetary Centrifugal Mixer SK-3000T

Model suited for the production of high specific gravity materials; up to 6 kg process, 2-cup system with a maximum weight of 3 kg per cup.

The wide radius gyration and centrifugal force can be achieved even at low

revolving speeds, keeping material composition change due to thermal elevation.

2000ml × 2 cups (3kg)

Vacuum Kakuhunters/Planetary Centrifugal Mixer

กรุณาเลือกรุ่นตามขนาดบรรจุตัวอย่าง

Select by capacity:

Planetary Centrifugal Mixer With Vacuum equipped

ModelSK-300TVSII

A high function model with a vacuum reduced pressure function.

The individual revolution and rotation speed control system and the shifted cup tray enhance mixing performance and provide effective degassing.

300ml × 2 cups

Planetary Centrifugal Mixer With Vacuum Equipped

ModelSK-350TV/ SK-350TVS

Greatly improved mixing performance with the same features as existing models!

A new advanced function model equipped with the individual revolution and rotation speed control system!!

400ml × 2 cups

Planetary Centrifugal Mixer With Vacuum Equipped

Model SK-1100TVII / SK-1100TVSII

A model with a vacuum reduced pressure function suited for medium-scale production.

The individual revolution and rotation speed control system and wide radius gyration generate centrifugal force even at low revolving speeds, sustaining material of thermal elevation and composition change.

1100ml × 2 cups

Only the TVS supports shifted cup trays

Entry Model Kakuhunter/Planetary Centrifugal Mixer

Planetary Centrifugal Mixer SK-300SII

A new entry model (SK-300SII) with enhanced functions!

“Medium mode” for minimizing mixing heat

“Wave mode” of enhancing mixing and dispersing force

300ml × 1 cup

Planetary Centrifugal Mixer SK-300SVII [Vacuum Type]

A compact, vacuum function, 1-cup, reasonable model with a simple mechanism.

With low revolving speed of 400G centrifugal force, it enables to control thermal elevation of materials.

300ml × 1 cup

Exclusive Model Kakuhunter/Planetary Centrifugal Mixer

Planetary Centrifugal Mixer for Microplate SK-MP12

Uniform mixing of samples in the microplate and ultrafine air bubble elimination with high speed processing.

This contributes to improved measurement result reliability.

- Multiple microplates can be set, so uniform mixing and ultrafine

air bubble elimination can be performed simultaneously in a short amount of

time. - By using an exclusive adopter, mixing and degassing are possible

with 18 or 96 well microplates, as well as 384 and 1536 well microplates as

full range. - Mixing and degassing of micro tubes and culture tubes are also

possible by having an adopter (as an option). - Total 12 PCR plates or microplates can be handled

simultaneously.

Long Barrel cartridge Series Planetary Centrifugal Mixer SK-BS12

A planetary centrifugal mixer specifically for long barrel cartridges, on which 12 oz (360 ml) and 6 oz (180 ml) cartridge can be set.

- The individual revolution and rotation speed control system achieves uniform mixing of materials in short amounts of time and elimination of ultrafine air bubbles.

- Productivity and operability can be improved by using cartridges with sizes suited for the amount to be produced (12 or 6 oz).* An exclusive adopter (spacer) is required to use 6 oz

cartridges.

Containers and Adopters

Various types of adopters are available for a wide range of

containers, including disposable cups, stainless steel containers, paper

containers, syringes, barrels, glass bottles, centrifuge tubes, etc.

By using one of the various adopters suited for syringes, re-dispersion can be conducted with different types of electronic materials (LED materials etc.) or chemical materials filled in the syringes.

In addition, the shifted cup tray used on the SK-300TVSII and SK-1100TVSII makes it possible to use longer syringes.

SK-2000T, we can modify cup trays for any container designated by the client, up to 2 kg per cup (maximum 150 mm × 170 mm).

You can use your current containers; there is no need to purchase new containers.

Furthermore, for all products, adopters (optional) can be used to mount containers or syringes designated by the client. (Depending on the shape of the container, it may not be possible to fit into cup trays.)

Cold adopters can be used to sustain thermal elevation of the material due to mixing heat.

In addition, the zirconium adopter makes it possible for powder crushing

application

Dispensing Machine

Shashin Kagaku also provides various types of dispensing machines suited for the clients’ materials and processes. Feel free to inquire.

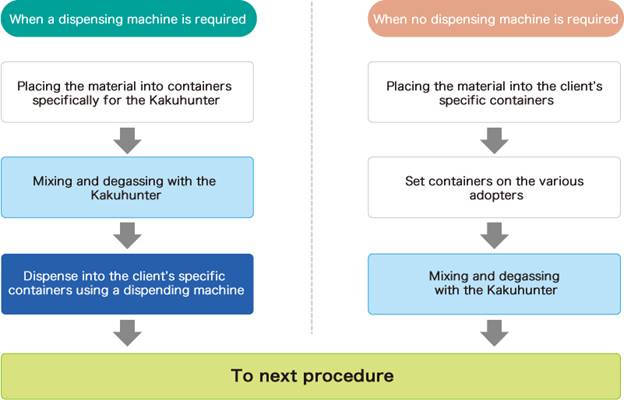

Kakuhunter using process

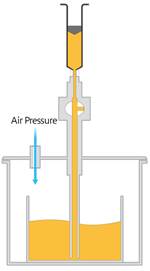

Pressurizing type

- The material containers are placed into a pressure tank and constantly pressurized by air pressure, and the material is dispensed by the switching of valves.

- This is suited for dispensing materials with low viscosity.

- This dispensing machine is relatively inexpensive.

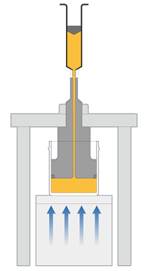

Table hoisting type

- The material containers are fixed to a table with precise control and the material is dispensed directly into syringes via a container adopter.

- It enables to fill effectively due to short and straight passing way for materials.

- Due to non-valve use, the structure of the wetted section is extremely simple and dispensing of the material in the containers is possible with little loss.

- The maximum dispensing load is high at 3 Mpa, so it is suitable for dispensing high viscosity or high thixotropy materials.