ผู้ผลิตเตาเผา เตาหลอม เตาสำหรับทดสอบขี้เถ้า (Ash Content Testing) สำหรับห้องแล็ป และเตาเผา เตาหลอมอุตสาหกรรมสำหรับการผลิตแก้ว เซรามิกส์ พลาสติก โลหะ เป็นต้น สามารถควบคุมอุณหภูมิในช่วง 30-3000 องศาเซลเซียส มีให้เลือกใช้หลากหลายขนาด

คลิ๊กด้านล่างเพื่อดูข้อมูลสินค้าเพิ่มเติม

Muffle/Preheating/Ashing Furnaces and

Accessories

|

|

| Muffle furnace L 3/12 |

Muffle furnace L 5/11 |

Muffle furnace LT 5/12

Muffle furnace L 3/11

Observation hole in the door as additional equipment

Over-temperature limiter

Gas supply system for non-flammable protective or reactive gas with shutoff valve and flow meter with regulator valve, optionally with magnetic valve

Adjustable air inlet integrated in the door

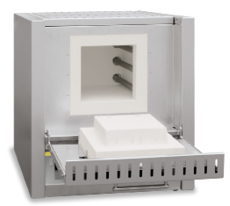

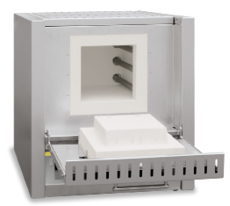

The muffle furnaces L 1/12 - LT 40/12 are the right choice for daily laboratory use. These models stand out for their excellent workmanship,

advanced and attractive design, and high level of reliability. The muffle furnaces come equipped with either a flap door or lift door at no extra charge.

- Tmax 1100 °C or 1200 °C

- Heating from two sides by ceramic heating plates (heating from three sides for muffle furnaces L 24/11 - LT 40/12)

- Ceramic heating plates with integral heating element which is safeguarded against fumes and splashing, and easy to replace

- Only fiber materials are used which are not classified as carcinogenic according to TRGS 905, class 1 or 2

- Housing made of sheets of textured stainless steel

- Dual shell housing for low external temperatures and high stability Optional flap door (L) which can be used as work platform or lift door (LT) with hot surface facing away from the operator

- Adjustable air inlet integrated in door (see illustration)

- Exhaust air outlet in rear wall of furnace

- Solid state relays provide for low-noise operation

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Chimney, chimney with fan or catalytic converter (not for L 1)

- Over-temperature limiter with adjustable cutout temperature for thermal protection class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace and load

- Protective gas connection to purge with non-flammable protective or reaction gases (not available in combination with chimney, chimney with fan or catalytic converter)

- Observation hole in the door

- Manual or automatic gas supply system

- Process control and documentation via VCD software package for monitoring, documentation and

control

Available

Model Number ; Flap door : L 3/11, L 5/11, L 9/11, L 15/11, L 24/11, L 40/11, L

1/12, L 3/12, L 5/12, L 9/12, L 15/12, L 24/12, L 40/12

Lift door : LT 3/11, LT 5/11, LT 9/11, LT 15/11, LT 24/11, LT 40/11, LT 3/12, LT 5/12, LT 9/12,

LT 15/12,

LT 24/12, LT 40/12

Muffle

Furnaces Basic Models

|

|

| Muffle furnace LE 1/11 |

Muffle furnace LE 6/11 |

Over-temperature limiter

With their unbeatable price/performance ratio, these compact muffle furnaces are perfect for many applications in the laboratory. Quality

features like the dual shell furnace housing of rust-free stainless steel, their compact, lightweight constructions, or the heating elements encased in quartz glass tubes make these models reliable partners for your application.

- Tmax 1100 °C, working temperature 1050 °C Heating from two sides from heating elements in quartz glass tubes

- Maintenance-friendly replacement of heating elements and insulation

- Only fiber materials are used which are not classified as carcinogenic according to TRGS 905, class 1 or 2

- Housing made of sheets of textured stainless steel

- Dual shell housing for low external temperatures and high stability

- Flap door which can also be used as a work platform

- Exhaust air outlet in rear wall

- Solid state relays provide for low-noise operation

- Compact dimensions and light weight

- Controller mounted under the door to save space

- Defined application within the constraints of the operating instructions

Additional equipment

- Chimney, chimney with fan or catalytic converter (not for L 1)

- Over-temperature limiter with adjustable cutout temperature for thermal protection class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace and load

- Protective gas connection to purge with non-flammable protective or reaction gases

- Manual gas supply system

- Observation hole in the door

Available

Model Number ; LE 1/11, LE 2/11,

LE 6/11, LE 14/11

Muffle Furnaces with Brick

Insulation and Flap Door or Lift Door

|

|

| Muffle furnace LT 5/13 |

Muffle furnace L 9/13 |

Furnace lining with high-quality lightweight refractory brick insulation

Over-temperature limiter

Heating elements on support tubes radiating freely into the

furnace chamber provide for particularly short heating times for these muffle

furnaces. Thanks to their robust lightweight refractory brick insulation, they

can reach a maximum working temperature of 1300 °C. These muffle furnaces thus

represent an interesting alternative to the familiar L(T) 3/11 models,

when you need particularly short heating times or a higher application

temperature.

- Tmax 1300 °C

- Heating from two

sides

- Heating elements on

support tubes ensure free heat radiation and a long service life

- Multi-layer

insulation with robust lightweight refractory bricks in the furnace

chamber

- Housing made of

sheets of textured stainless steel

- Dual shell housing

for low external temperatures and stability

- Optional flap door

(L) which can be used as work platform or lift door (LT) with hot surface

facing away from the operator

- Adjustable air

inlet in the furnace door

- Exhaust air outlet

in rear wall of furnace

- Solid state relays

provide for low-noise operation

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Chimney, chimney

with fan or catalytic converter

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Protective gas

connection to purge with non-flammable protective or reaction gases

- Manual or automatic

gas supply system

- Observation hole in

the door

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available

Model Number ; L, LT 5/13, L, LT

9/13, L, LT 15/13

Muffle Furnaces up to 1400

°C

|

|

|

Muffle furnace L 9/14

|

Muffle furnace L 15/14

|

Over-temperature

limiter

Gas supply

system for non-flammable protective or reactive gas with shutoff valve and flow

meter with regulator valve, optionally with magnetic valve

These models stand out for their excellent workmanship, advanced

and attractive design, and high level of reliability. Heating elements on

support tubes radiating freely into the furnace chamber provide for

particularly short heating times and a maximum temperature of 1400 °C.

These muffle furnaces are a good alternative to the familiar L(T) ../11 series

when higher application temperatures are needed.

- Tmax 1400 °C

- Heating from two sides

- Heating elements on support tubes ensure free heat radiation and a long service life

- Only fiber materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Dual shell housing for low external temperatures and high stability

- Adjustable air inlet integrated in door

- Exhaust air outlet in rear wall of furnace

- Solid state relays provide for low-noise operation

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Chimney, chimney with fan or catalytic converter

- Over-temperature limiter with adjustable cutout temperature for thermal protection class 2 in accordance with EN 60519-2 as temperature limiter to protect the furnace and load

- Protective gas connection to purge with non-flammable protective or reaction gases (not available in combination with chimney, chimney with fan or catalytic converter)

- Manual or automatic gas supply system

- Process control and documentation via VCD software package for monitoring, documentation and control

Available

Model Number ; L, LT 5/14, L, LT

9/14, L, LT 15/14

Muffle

Furnaces with Embedded Heating Elements in the Ceramic Muffle

|

| L 9/11/SKM |

Muffle heated

from four sides

Gas supply

system for non-flammable protective or reactive gas with shutoff valve and flow

meter with regulator valve, optionally with magnetic valve

Over-temperature

limiter

We particularly recommend the muffle furnace L 9/11/SKM if your

application involves aggressive substances. The furnace has a ceramic muffle

with embedded heating from four sides. The muffle furnace thus combines a very

good temperature uniformity with excellent protection of the heating elements

from aggressive atmospheres. Another aspect is the smooth, nearly particle free

muffle (furnace door made of fiber insulation), an important quality feature

for some ashing processes.

- Tmax 1100 °C

- Muffle heated from

four sides

- Furnace chamber

with embedded ceramic muffle, high resistance to aggressive gasses and

vapours

- Dual shell housing

made of sheets of textured stainless steel

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Optional flap door

(L) which can be used as work platform or lift door (LT) with hot surface

facing away from the operator

- Adjustable working

air inlet in the door

- Exhaust air outlet

in rear wall of furnace

- Solid state relays

provide for lownoise operation

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Chimney, chimney

with fan or catalytic converter

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Protective gas

connection to purge with non-flammable protective or reaction gases

- Manual or

automation gas supply system

- Observation hole in

the door

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available

Model Number ; L 9/11/SKM, LT

9/11/SKM

Ashing

Furnaces with Flap Door or Lift Door

|

|

| Ashing furnace LV 3/11 |

Ashing furnace LVT 9/11 |

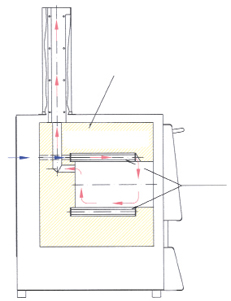

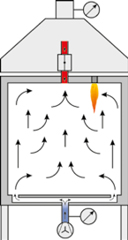

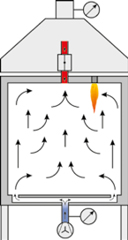

Air inlet

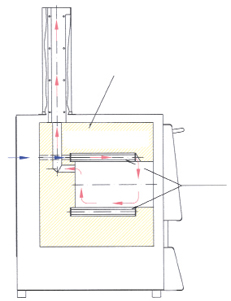

and exhaust flow principle in ashing furnaces

Observation

hole in the door as additional equipment

Over-temperature

limiter

The ashing furnaces LV 3/11 - LVT 15/11 are especially designed

for ashing in the laboratory. A special air intake and exhaust system allows

air exchange of more than 6 times per minute. Incoming air is preheated to

ensure a good temperature uniformity.

- Tmax 1100 °C

- Heating from two

sides

- Ceramic heating

plates with integral heating element which is safeguarded against fumes

and splashing, and easy to replace

- Air exchange of

more than 6 times per minute

- Good temperature

uniformity due to preheating of incoming air

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Housing made of

sheets of textured stainless steel

- Dual shell housing

for low external temperatures and stability

- Optional flap door

(LV) which can be used as work platform or lift door (LVT) with hot

surface facing away from the operator

- Solid state relays

provide for lownoise operation

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Observation hole in

the door

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available

Model Number ;

Flap door : LV 3/11, LV 5/11,

LV 9/11, LV 15/11,

Lift door: LVT 3/11, LVT 5/11, LVT 9/11, LVT15/11

Ashing Furnaces with Integrated

Exhaust Gas Cleaning

|

|

|

Ashing furnace L 40/11 BO |

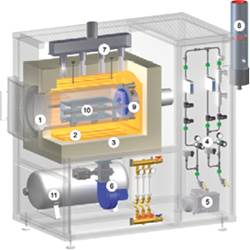

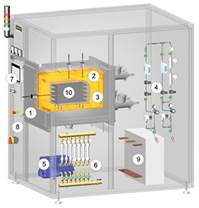

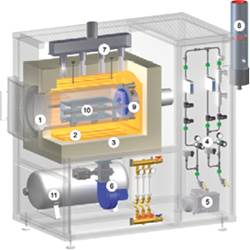

The ashing furnace L ../11 BO is specially designed for

processes in which larger sample quantities have to be incinerated. Fields of

application are e.g. the ashing of food, thermal cleaning of injection molding

tools or the determination of annealing loss. Another application is the

debinding of ceramic products, e.g. after additive production.

The ashing furnaces have a passive safety system and integrated

exhaust gas post combustion. An exhaust gas fan extracts flue gases from the

furnace and simultaneously supplies fresh air to the furnace atmosphere with

the result that sufficient oxygen is always available for the incineration

process. The incoming air is guided behind the furnace heating and preheated to

ensure good temperature uniformity. Exhaust gases are led from the furnace

chamber to the integrated post combustion system, where they are postburned and

catalytically cleaned. Directly after the incineration process (up to max.

600 °C) a subsequent process up to max. 1100 °C can take place.

- Tmax 600 °C for the

incineration process

- Tmax 1100 °C for

the subsequent process

- Three-side heating

(both sides and bottom)

- Ceramic heating

plates with embedded heating wire

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Dual shell housing

made of structured stainless steel provides for low outer temperature and

high stability

- Steel collecting

pan protects the bottom insulation

- Spring-assisted

closing of the furnace door (flap door) with mechanical locking against

unintentional opening

- Thermal/catalytic

post combustion, integrated in the exhaust channel, up to 600 °C in

function

- Temperature control

of post combustion can be set up to 850 °C

- Monitored exhaust

air

- Inlet-air preheated

through the bottom heating plate

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available Model Number ;

L 9/11 BO, L 24/11 BO, L 40/11 BO

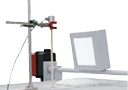

Weighing Furnace incl. Scale and Software for Determination of

Combustion Loss

|

| Weighing furnace L 9/11/SW |

4 scales

available for different maximum weights and scaling areas

Over-temperature

limiter

Software

for documentation of the temperature curve and combustion loss using a PC

This weighing furnace with integrated precision scale and

software, was designed especially for combustion loss determination in the

laboratory. The determination of combustion loss is necessary, for instance,

when analyzing sludges and household garbage, and is also used in a variety of

technical processes for the evaluation of results. The difference between the

initial total mass and the combustion residue is the combustion loss. During

the process, the software included records both the temperature and the weight

loss.

- Tmax 1100 °C or

1200 °C

- Heating from two

sides

- Ceramic heating

plates with integral heating element which is safeguarded against fumes

and splashing, and easy to replace

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Dual shell housing

made of sheets of textured stainless steel

- Optional flap door

(L) which can be used as work platform or lift door (LT) with hot surface

facing away from the operator

- Adjustable working

air inlet in the door

- Exhaust air outlet

in rear wall of furnace

- Solid state relays

provide for lownoise operation

- Delivery includes

base, ceramic plunger with base plate in the furnace lining, precision

scale and software package

- 4 scales available

for different maximum weights and scaling ranges

- Process control and

documentation for temperature and combustion loss via VCD software package

for monitoring, documentation and control

- Defined application

within the constraints of the operating instructions

Additional equipment

- Chimney, chimney

with fan or catalytic converter

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Observation hole in

the door

Available

Model Number ;

flap door : L 9/11/SW, L 9/12/SW

Lift door : LT 9/11/SW, LT 9/12/SW

Exhaust

Systems/Accessories

* Note: If other controller types are used an adapter cable for

connection to mains supply has to be ordered separately. The device will be

activated by plugging in the socket.

|

|

|

|

|

Chimney for connection to an

exhaust pipe.

|

Chimney with fan, to remove

exhaust gas from the furnace

better.

The B400 - P480 controllers

can be

used to activate the fan

automatically (not for

models L(T) 15..,

L 1/12, LE 1/11, LE 2/11).*

|

Catalytic

converter with fan for

removal of

organic components from

the exhaust

air. Organic components are catalytically oxidized at about 600 °C, broken

into carbon dioxide and water vapour. Irritating odors are thus largely

eliminated. The B400 - P480 controllers can be used to switch the catalytic

converter automatically (not for models L(T) 15.., L 1/12,

LE 1/11, LE 2/11).*

|

|

|

|

|

|

Exhaust torch to burn exhaust

gases which are generated during the process. The torch is gas-fired and will

be operated with propane gas. If a catalytic post combustion cannot be used

for the process this torch is recommended.

|

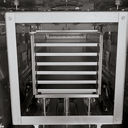

Square saggar for furnaces

LHTC and LHT, Tmax 1600 °C The load is placed in ceramic saggars for optimal

utilization of the furnace space. Up to three saggars can be stacked on top

of each other in the furnace. Each saggar has cut-outs for better

ventilation. The top saggar should be closed with a lid made of ceramics

also.

|

Round saggar (Ø 115 mm) for

furnaces LHT/LB, Tmax 1650 °C These saggars are perfectly suited for furnaces

LHT/LB. The load is placed in the saggars. Up to three saggars can be stacked

on top of each other in order to use the overall furnace chamber.

|

|

|

|

|

|

|

|

|

|

|

Additional equipment

- Base frame on

castors (not for assay furnace N 4/13 CUP)

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Pit-type furnace with rolling lid

- For bigger charges

we offer pit-type furnaces as assay furnaces

Available

Model Number : N 4/13 CUP, N 8/13 CUP, N 25/13 CUP

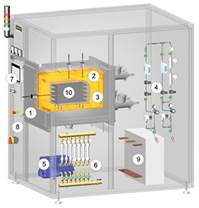

Chamber Furnaces for Annealing, Hardening

and Brazing

|

|

|

|

Chamber furnace N 7/H as table-top

model

|

Chamber furnace N 61/H

|

Working with protective gas boxes for a protective gas

atmosphere using a charging cart

To

withstand harsh use in the laboratory, e.g. when heat-treating metals, robust

insulation with light refractory bricks is necessary. The chamber furnaces N

7/H - N 87/H are a perfect fit to solve this problem. The furnaces can be

extended with a variety of accessories, like annealing boxes for operation

under protective gas, roller guides, or a cooling station with a quench tank.

Even high-performance applications like the annealing of titanium in medical

applications can be implemented without the use of expensive and complicated

annealing systems.

- Tmax 1280 °C

- Deep furnace

chamber with three-sides heating: from both side walls and bottom

- Heating elements on

support tubes ensure free heat radiation and a long service life

- Bottom heating

protected by heat-resistant SiC plate

- Low energy

consumption due to multi-layer insulation

- Exhaust opening in

the side of the furnace, or on back wall of chamber furnace N 31/H and

higher

- Base frame included

in the delivery, N 7/H - N 17/HR designed as table-top model

- Parallel guided

downward swinging door (user protected from heat radiation)

- Gas spring dampers

provide for easy door opening and closing

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Available Model Number:

N 7/H, N 11/H, N 11/HR, N 17/HR

, N 31/H, N 41/H, N 61/H, N 87/H

Chamber Furnaces with Brick Insulation or Fiber Insulation up to 1400 °C

|

|

| Chamber furnace LH 216/12SW with scale to

measure weight reduction during annealing |

Chamber furnace LF 60/14 with fresh air fan to

accelerate the cooling times |

Chamber

furnace LH 30/14

Chamber

furnace LH 30/12 with manual lift door

LF furnace design provides for

shorter heating and cooling times

The chamber furnaces LH 15/12 - LF 120/14 have been trusted for

many years as professional chamber furnaces for the laboratory. These furnaces

are available with either a robust insulation of light refractory bricks (LH

models) or with a combination insulation of refractory bricks in the corners

and low heat storage, quickly cooling fiber material (LF models). With a wide

variety of optional equipment, these chamber furnaces can be optimally adapted

to your processes.

- Tmax 1200 °C, 1300

°C, or 1400 °C

- Dual shell housing

with rear ventilation, provides for low shell temperatures

- High furnace

chamber with five-sided heating for very good temperature uniformity

- Heating elements on

support tubes ensure free heat radiation and a long service life

- Controller mounted

on furnace door and removable for comfortable operation

- Protection of

bottom heating and flat stacking surface provided by embedded SiC plate in

the floor

- LH models:

multi-layered insulation of light refractory bricks and special backup

insulation

- LF models: high-quality

fiber insulation with corner bricks for shorter heating and cooling times.

Only fiber materials are used which are not classified as carcinogenic

according to TRGS 905, class 1 or 2.

- Door with

brick-on-brick seal, hand fitted

- Short heating times

due to high installed power

- Self-supporting

arch for high stability and greatest possible protection against dust

- Quick lock on door

- Motor driven

exhaust air flap

- Freely adjustable

air inlet integrated in furnace floor

- Base included

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Parallel swinging

door, pivots away from operator, for opening when hot

- Lift door with

electro-mechanic linear drive

- Separate

wall-mounting or floor standing cabinet for switchgear

- Cooling fan for

shorter cycle times

- Protective gas

connection to purge with non-flammable protective or reaction gases

- Manual or automatic

gas supply system

- Scale to measure

weight reduction during annealing

- Process control and

documentation via VCD software package or Nabertherm Control Center (NCC)

for monitoring, documentation and control

Available

Model Number : LH 15/12, LH 30/12, LH 60/12, LH 120/12, LH

216/12, LH 15/13, LH 30/13, LH 60/13,

LH 120/13, LH 216/13, LH 15/14, LH 30/14, LH 60/14, LH

120/14, LH 216/14 , LF 15/13, LF 30/13, LF 60/13, LF 120/13, LF 15/14, LF

30/14, LF 60/14, LF 120/14

High-Temperature Furnaces/Sintering

Furnaces

High-Temperature Furnaces with SiC

Rod Heating up to 1600 °C

|

|

| High-temperature furnace LHTC 08/16 |

High-temperature furnace LHTCT 01/16 |

Furnace

chamber with high-quality fiber materials and SiC heating rods on both sides of

the furnace

Saggars

with top lid

Over-temperature

limiter

These powerful laboratory muffle furnaces are available for

temperatures up to 1400 °C, 1500 °C, 1550 °C or 1600 °C. The

durability of the SiC rods in periodic use, in combination with their high

heating speed, make these high-temperature furnaces to all-rounders in the

laboratory. Heating times of 40 minutes to 1400 °C can be achieved,

depending on the furnace model and the conditions of use.

- Tmax 1400 °C, 1500

°C, 1550 °C or 1600 °C

- Working temperature

1500 °C (for high-temperature furnaces LHTC ../16), increased wear and

tear must be expected in case of working at higher temperatures

- Dual shell housing

made of textured stainless steel sheets with additional fan cooling for

low surface temperature

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Optional flap door

(LHTC) which can be used as work platform or lift door (LHTCT) with hot

surface facing away from the operator (High-temperature furnace LHTCT

01/16 only with lift door)

- Switching system

with solid-state-relays, power tuned to the SiC rods

- Easy replacement of

heating rods

- Adjustable air

inlet opening, exhaust air opening in the roof

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Square saggar for

charging of up to three layers

- Lid for top saggar

- Manual or automatic

gas supply system

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available Model Number :

LHTC(T) 03/14, LHTC(T) 08/14, LHTC(T) 03/15,

LHTC(T) 08/15, LHTCT 01/16, LHTC(T) 03/16, LHTC(T) 08/16

High-Temperature Furnaces with MoSi2

Heating Elements up to 1800 °C

|

|

| High-temperature furnace LHT 01/17 D |

High-temperature furnace LHT 03/17 D |

Saggars

with top lid

Over-temperature

limiter

Designed as tabletop models, these compact high-temperature

furnaces have a variety of advantages. The first-class workmanship using

high-quality materials, combined with ease of operation, make these furnaces

all-rounders in research and the laboratory. These high-temperature furnaces are

also perfectly suited for the sintering of technical ceramics, such as

zirconium oxide dental bridges.

- Tmax 1600 °C, 1750

°C, or 1800 °C

- High-quality

molybdenum disilicide heating elements

- Dual shell housing

made of textured stainless steel sheets with additional fan cooling for

low surface temperature

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Compact design with

lift door, opening upwards

- Adjustable air

inlet

- Exhaust air opening

in the roof

- Type B thermocouple

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Square saggar for

charging of up to three layers

- Protective gas

connection to purge with non-flammable protective or reaction gases

- Manual or automatic

gas supply system

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available Model

Number : LHT 02/16, LHT 04/16, LHT 08/16, LHT 01/17 D, LHT 03/17

D, LHT 02/17, LHT 04/17,

LHT

08/17, LHT 02/18, LHT

04/18, LHT 08/18

High-Temperature

Bottom Loading Furnaces up to 1700 °C

,

|

|

| LHT 16/17 LB |

High-temperature furnace LHT 02/17 LB with a set of saggars |

Electrically

driven lift-bottom

Saggar

The motor-driven lifting table significantly simplifies the

charging of the high-temperature furnaces LHT/LB. The heating all around the

cylindrical furnace chamber provides for an opitimal temperature uniformity.

For the tabletop models LHT 01/17 LB and LHT 02/17 LB the charge can be placed

in charge saggars made of technical ceramics. Up to three charge saggars can be

stacked on top of each other resulting in a high productivity. Due to its

volume the high-temperature furnace LHT 16/17 LB can also be used for

applications in production.

- Tmax 1650 °C, 1700

°C (LHT 16/17 LB)

- High-quality

heating elements made of molybdenum disilicide offer best possible

protection against chemical interaction between charge and heating

elements

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Outstanding

temperature uniformity due to all-round furnace chamber heating

- Furnace chamber

with a volume of 1, 2 or 16 liters, table with large floor space

- Precise, motorized

toothed belt drive of the table with button operation

- Appealing, dual

shell stainless steel housing

- Exhaust air vent in

the roof

- Type S thermocouple

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Stackable saggars

for loading in up to two or three levels, depending on model

- Protective gas

connection to purge with non-flammable protective or reaction gases

- Manual or automatic

gas supply system

- Adjustable air

inlet through the floor

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available Model Number :

LHT 01/17 LB, LHT 02/17 LB, LHT 16/17 LB

High-Temperature Furnaces with Scale

for Determination of Combustion Loss and Thermogravimetric Analysis (TGA)

|

|

|

High-temperature furnace LHT

04/16 SW with scale for measuring weight reduction during annealing and with

gas supply system

|

Software for documentation of the temperature curve and

combustion loss using a PC

These high-temperature

furnaces were specially developed to determine combustion loss during annealing

and for thermogravimetric analysis (TGA) in the lab. The complete system

consists of the high-temperature furnace for 1600 °C or 1750 °C, a

table frame, precision scale with feedthroughs into the furnace and powerful

software for recording both the temperature curve and the weight loss over

time.

- Defined application

within the constraints of the operating instructions

- Technical

description of the furnaces: see models LHT 04/16 and LHT 04/17

- Description of the

weighing system: see models L 9/... SW

- Process control and

documentation for temperature and combustion loss via VCD software package

for monitoring, documentation and control

Available Model Number :

LHT 04/16 SW, LHT 04/17 SW

High-Temperature

Furnaces with Molybdenum Disilicide Heating Elements with Fiber Insulation up

to 1800 °C

|

|

|

|

High-temperature furnace HT

16/18 with gas supply system

|

High-temperature furnace HT

160/17 with gas supply system

|

Reinforced floor as protection for bottom insulation for

high-temperature furnace HT 16/16 and higher

Inner

process top hat with gas injection through the furnace bottom protects the

furnace chamber against contamination and/or prevents chemical interaction

between the charge and heating elements

High-temperature furnace HT 64/16S with pneumatically

driven and parallel lift door

Two-door design for high-temperature furnaces > HT 276/..

Available

Model Number : HT 04/16, HT 08/16, HT 16/16, HT 40/16, HT

64/16, HT 128/16, HT 160/16, HT 276/16,

HT 450/16, HT 04/17, HT 08/17, HT 16/17, HT 40/17, HT

64/17, HT 128/17, HT 160/17, HT 276/17, HT 450/17, HT 04/18,

HT

08/18, HT 16/18, HT

40/18, HT 64/18, HT 128/18, HT 160/18, HT 276/18, HT 450/18,

High-Temperature

Furnaces with SiC Rod Heating up to 1550 °C

|

|

|

High-temperature furnace HTC

40/16

|

Vertically mounted SiC rods and optional perforated air inlet

tubes of the debinding system in a high-temperature furnace

Exhaust air flap and charge thermocouple including a stand as

additional equipment

The

high-temperature furnaces HTC 16/16 - HTC 450/16 are heated by vertically hung

SiC rods, which makes them especially suitable for sintering processes up to a

maximum operating temperature of 1550 °C. For some processes, e.g. for

sintering zirconium oxide, the absence of interactivity between the charge and

the SiC rods, these models are more suitable than the alternatives heated with

molybdenum disilicide elements. The basic construction of these furnaces make

them comparable with the already familiar models in the HT product line and

they can be upgraded with the same additional equipment.

- Tmax 1550 °C

- Dual shell housing

with fan cooling for low shell temperatures

- Heating from both

sides via vertically mounted SiC rods

- High-quality fiber

insulation backed by special insulation

- Side insulation

constructed with tongue and groove blocks provides for low heat loss to

the outside

- Long-life roof

insulation with special suspension

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Chain-guided

parallel swivel door for defined opening and closing of the door without

destroying the insulation

- Two-door design

(front/back) for high-temperature furnaces > HTC 276/..

- Labyrinth sealing

ensures the least possible temperature loss in the door area

- Reinforced floor as

protection for bottom insulation

- Exhaust air opening

in the furnace roof

- Heating elements

switched via SCR's

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Available Model

Number : HTC 16/16, HTC

40/16, HTC 64/16, HTC 128/16, HTC 160/16, HTC 276/16, HTC 450/16

High Temperature Furnaces with

Molybdenum Disilicide Heating Elements with Refractory Brick Insulation up to

1700 °C

|

|

| High-temperature furnace HFL 16/17 DB50 |

High-temperature furnace HFL 160/17 |

Protection

grid in front of heating elements prevent against mechanical damages

Gas supply

system for non-flammable protective or reaction gases

The high-temperature furnaces HFL 16/16 HFL 160/17 are

characterized by their lining with robust light refractory bricks. This version

is recommended for processes producing aggressive gases or acids, such as under

glass melting.

Standard equipment like

high-temperature furnaces HT, except:

- Tmax 1600 °C

or 1700 °C

- Robust refractory

brick insulation and special backing insulation

- Furnace floor made

of lightweight refractory bricks accommodates high charge weights

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Available

Model Number : HFL 16/16, HFL 40/16, HFL 64/16, HFL 160/16,

HFL 16/17, HFL 40/17, HFL 64/17,

HFL 160/17

Ovens and Forced Convection Chamber

Furnaces

|

|

| Oven TR 60 with adjustable fan speed |

Oven TR 240 |

Electrical

rotating device as additional equipment

Extricable

metal grids to load the oven in different layers

Oven TR

1050 with double door

Oven

TR 120 LS with safety technology according to EN 1539 for charges

containing liquid solvents

Oven TR

450

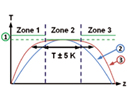

With their maximum working temperature of up to 300 °C and air

circulation, the ovens achieve a perfect temperature uniformity which is much

better than in ovens of most competitors. They can be used for various

applications such as e.g. drying, sterilizing or warm storing. Ample

warehousing of standard models provides for short delivery times.

- Tmax 300 °C

- Working temperature

range: + 5 °C above room temperature up to 300 °C

- Ovens TR 30 - TR

240 designed as tabletop models

- Ovens TR 450 and TR

1050 designed as floor standing models

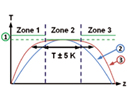

- Horizontal, air

circulation results in temperature uniformity better than +/- 5 °C

- Stainless steel

chamber, alloy 304 (AISI)/(DIN material no. 1.4301), rust-resistant and

easy to clean

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Large handle to

open and close the door

- Charging in

multiple layers possible using removeable grids (number of removeable

grids included, see table to the right)

- Large, wide-opening

swing door, hinged on the right with quick release for models TR 30 - TR

450

- Double swing door

with quick release for TR 1050

- TR 1050 equipped

transport rollers

- Infinitely

adjustable exhaust at the rear wall with operation from the front

- PID microprocessor

control with self-diagnosis system

- Solid state relays

provide for lownoise operation

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the oven

and load

- Infinitely

adjustable fan speed of the air circulation fan

- Window for charge

observing

- Further removeable

grids with rails

- Side inlet

- Stainless steel

collecting pan to protect the furnace chamber

- Door hinges on the

left side

- Reinforced bottom

plate

- Safety technology

according to EN 1539 for charges containing liquid solvents

(TR .. LS) up to model TR 240 LS, achievable

temperature uniformity +/- 8 °C

- Transport castors

for model TR 450

- Various

modifications available for individual needs

- Upgrading available

to meet the quality requirements of AMS 2750 E or FDA

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available Model Number :

TR 30, TR 60, TR 60 LS, TR 120, TR 120 LS, TR 240, TR 240 LS, TR 450,

TR 1050

Chamber Ovens Electrically Heated or

Gas-Fired

|

|

| Chamber oven KTR 1500 with charging cart |

Chamber oven KTR 22500/S with chamber lightning and drive-in

tracks with insulated plugs which provide for an optimal temperature

uniformity |

KTR 3100/S

for curing of composites in vacuum bags incl. pump and necessary connections in

the oven chamber

Direct

gas-firing at a chamber dryer

KTR 4500

with platform cart, inner lightning and observation windows

Adjustable

plate shutters to adapt the air guide to the charge

KTR 3100

DT with rotating system for tempering of silicone parts. Four baskets will be

charged in the frame and can be taken out separately

Drive-in

ramp

The chamber ovens of the KTR range can be used for complex

drying processes and heat treatment of charges to an application temperature of

260 °C. The high-performance air circulation enables optimum temperature

uniformity throughout the work space. A wide range of accessories allow the

chamber ovens to be modified to meet specific process requirements. The design

for the heat treatment of flammable materials in conformance with EN 1539

(NFPA 86) is available for all sizes.

- Tmax 260 °C

- Electrically heated

(via a heating register with integrated chrome steel heating elements) or

gas-fired (direct or indirect gas-fired including injection of the hot air

into the intake duct)

- Temperature

uniformity up to +/- 3 °C according to DIN 17052-1 (for

design wihout track cutouts)

- High-quality

mineral wool insulation provides for outer temperatures of < 25

°C above room temperature

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- High air exchange

for fast drying processes

- Double-wing door

for furnaces KTR 3100 and larger

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the oven

and load

- Incl. floor

insulation

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Track cutouts for

level drive-in of charging cart

- Base frame to

charge the oven via a charging forklift

- Additional Door in

the back for charging from both sides or to use the oven as lock between

two rooms

- Fan system for

faster cooling with manual or motor-driven control of the exhaust flaps

- Programmed opening

and closing of exhaust air flaps

- Air circulation

with speed control, recommendable for processes with light or sensitive

charge

- Observation window

and furnace chamber lighting

- Safety technology

according to EN 1539 (NFPA 86) (models KTR .. LS) for charges

containing solvents

- Charging cart with

or without rack system

- Design for clean

room heat treatment processes

- Rotating systems

for tempering processes

- Process control and

documentation via VCD software package or Nabertherm Control Center (NCC)

for monitoring, documentation and control

Accessories

- Adjustable plate

shutters to adapt the air guide to the charge and improve temperature

uniformity

- Guide-in tracks and

shelves

- Shelves with 2/3

extraction with evenly distributed load on the whole shelve surface

- Platform cart in

combination with drive-in tracks

- Charging cart with

rack system in combination with drive-in tracks

- Sealing shoes for

ovens with drive-in tracks to improve temperature uniformity in the work

space

- All KTR-models are

also available with Tmax 300 °C.

Available Model Number :

KTR 1000 (LS), KTR 1500 (LS), KTR 3100 (LS), KTR 4500 (LS), KTR 6125

(LS), KTR 6250 (LS), KTR 8000 (LS), KTR 9000 (LS), KTR 12300 (LS), KTR 16000

(LS), KTR 21300 (LS), KTR 22500 (LS)

High-Temperature Ovens, Forced

Convection Chamber Furnaces

|

|

|

|

Forced convection chamber

furnace NA 250/45

|

Forced convection chamber

furnace NA 120/46 with lift door

|

Forced convection chamber furnace NA 15/65 as table-top

model

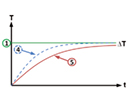

These

chamber furnaces with air circulation are characterized by their extremely high

temperature uniformity. Hence, they are especially suitable for processes such

as cooling, crystalizing, preheating, curing, but also for numerous processes

in tool making. Due to the modular concept, the forced convection furnaces can

be adjusted to the process requirements by adding suitable equipment.

- Tmax 450 °C, 650

°C, or 850 °C

- Horizontal air

circulation

- Swing door hinged

on the right

- Temperature

uniformity up to +/- 4 °C according to DIN 17052-1 (model NA 15/65 up to

+/- 5 °C)

- Optimum air flow

and temperature uniformity through high circulation rates

- One frame sheet and

rails for two additional trays included in the scope of delivery (NA 15/65

without frame sheet)

- Stainless steel

air-baffles in the furnace for optimum air circulation

- Base frame included

in the delivery, NA 15/65 designed as table-top model

- Air inlet and

exhaust air flaps as additional equipment for using as drying oven

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Available

Model Number : NA 30/45, NA 60/45, NA 120/45, NA 250/45, NA

500/45, NA 15/65, NA 30/65, NA 60/65, NA 120/65, , NA 250/65, NA 500/65, N 30/85 HA, N 60/85 HA, N 120/85 HA, N 250/85

HA, N 500/85 HA

Sealed Forced Convection Chamber Furnaces NA-I and NA-SI

|

|

| Forced convection chamber furnace NA 120/65 I |

Forced convection chamber furnace NA 15/65 I as tabletop

model with manual gas supply system |

Sealed forced convection chamber furnaces are suitable if a heat

treatment process up to 650 °C requires a protective gas atmosphere that does

not have to be completely oxygen free. The difference between the two variants

is that the I-model only has a sealed outer housing while the SI-model has a

welded inner box, which further reduces the residual oxygen concentration.

NA-I design Like

forced convection chamber furnaces < 675 l (page 34) with the following

changes

- Tmax 450 °C and 650

°C

- Silicone door seal

- Furnace housing

sealed with silicone

- Protective gas

connection in the back wall

- Defined application

within the constraints of the operating instructions

- Residual oxygen

concentration < 1 % depending on the volume and type of protective

gas

- For non-flammable

protective and reaction gases such as argon, nitrogen, and forming gas

(national regulations must be considered)

NA-SI design Additional

features

- Tmax 650 °C

- Welded inner

housing

- 2-sided heating and

air circulation

- Door sealed with

seal gas

- Sealed connection

to circulation motor

- Gas inlet via

circulator shaft

- Defined application

within the constraints of the operating instructions

- Residual oxygen

concentration to 0.1 % depending on the volume and type of protective

gas

- For non-flammable

protective and reaction gases such as argon, nitrogen, and forming gas

(national regulations must be considered)

Available

Model Number : NA 30/45 I, NA 60/45 I, NA 120/45 I, NA

250/45 I, NA 500/45 I, NA 675/45 I, NA 15/65 I1, NA 30/65 I, N A 60/65 I (SI), NA 120/65 I (SI), NA 250/65 I (SI), NA 500/65

I (SI), NA 675/65 I

Chamber Furnaces for Processes with High Vaporization Rates

of Organic Matter or for Thermal Cleaning by Ashing Electrically Heated or

Gas-Fired

Chamber

furnace N 650/14 BO with ignition burner

The chamber furnaces of the model series N(B) .. BO

are used for processes with large amounts of organic matters or high

vaporization rates. These models can be used for products which are insensitive

against temporarily uncontrolled temperature increases. Processes in which the

product or contaminations on the product are ashed by ignition can be also

carried out safely in this type of chamber furnace. Examples include residual

wax removal of pouring clustersfollowed by sintering, or thermal cleaning of

oxide catalytic honey combs from soot or fuel residues. The electrically heated

N...BO furnaces can be used for processes with exact temperature control and

uniformity. For safety reasons, they are equipped with an integrated gas torch

for igniting the flammable components in the gas mixture. The accumulation of

flammable components is avoided and their safe combustion is ensured.

The gas-fired NB…BO furnaces are designed for processes which

require a heat-up time to temperatures > 500 °C

The burning of unwanted organic ingrediants can take place at

temperatures > 500 °C. Following this, a subsequent process can take place

up to max. 1400 °C (electrically) or up to 1000 °C (gas-fired).

For safety, the furnace door locks after the program was started

and cannot be opened again until the temperature has dropped below a defined

value. In case of burner malfunction or gas shortage the process is aborted.

Chamber furnaces N 100 BO - N

650/14 BO, electrically heated and gas-fired ignition flame

- Tmax 1000 °C or

1400 °C

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Standard sizes up

to 650 liters furnace chamber, additional sizes on request

- Exhaust hood

- Fully automatic

temperature control

- Optional thermal

afterburning

- Ignition flame using

natural gas or liquid gas (LPG)

- Defined application

within the constraints of the operating instructions

Chamber furnaces models NB 300 BO

and NB 650 BO, gas-fired

- Tmax 1000 °C

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Standard sizes up

to 650 liters furnace chamber, additional sizes on request

- Integrated thermal

afterburning

- Gas burners

operating with natural gas or liquid gas (LPG)

- Defined application

within the constraints of the operating instructions

Available Model Number :

N 100 BO, N 300 BO, N 300/14 BO, N 650/14 BO, NB 300 BO, NB 650 BO

Clean Room Solutions

|

|

|

|

KTR 8000 designed as a

production oven in the clean room with filters for air circulation

|

Hot-wall retort furnace NRA

1700/06 with charging frame for installation in grey room with charging door

in clean room

|

High-temperature furnace with loading from the clean room;

switchgear and furnace installed in grey room

Forced convection chamber oven NAC 250/45 with clean room specs

Clean room

applications impose particularly high requirements to the design of the chosen

furnace. If the complete furnace is operated in a clean room an essential

contamination of the clean room atmosphere must be avoided. Especially, the

particle contamination must be reduced to a minimum.

The

specific application determines the choice of the required furnace technology.

In many cases forced convection furnaces are required to achieve the necessary

temperature uniformity at lower temperatures. For higher temperatures,

Nabertherm has also delivered many furnaces with radiant heating.

Furnace Installation in the Clean Room

If the

complete furnace is supposed to be positioned in the clean room, then it is

important that both the furnace chamber and the furnace housing as well as the

controls provide for good protection against contamination. Surfaces must be

easy to clean. The furnace chamber is tightly sealed to the insulation behind

it. If necessary, additional equipment such as filters for the fresh air supply

or the air circulation in the furnace can be used to improve the cleanliness

class. It is recommended to install the switchgear and the furnace controls

outside the clean room.

Furnace Installation in the Grey Room, Furnace Charging from the

Clean Room

Optimal

results with respect to cleanness will be achieved by placing the furnace in

the grey room with charging from the clean room. This significantly reduces the

amount of costly space needed in the clean room to a minimum. The front and the

furnace interior in the clean room are designed for easy cleaning. With this

configuration even the highest clean room classes can be achieved.

Sluice Furnace between Grey Room and Clean Room

Logistics

between clean room and grey room can often be easily sorted out. Lock furnaces

with one door in the grey room and the other door in the clean room are the

perfect choice for these applications. The inner chamber as well as the furnace

front in the clean room will be especially designed for lowest particle contamination.

Please

contact us if you are looking for a heat treatment solution under clean room

conditions. We would be pleased to quote for the oven or furnace model that

meets best your requirements.

Tube Furnaces and Accessories

|

| RD 30/200/11 |

Over-temperature

limiter

The RD tube furnaces convince with their unbeatable

price-performance ratio, very compact outer dimensions and their low weight.

These all-rounders are equipped with a working tube which also serves as

support for the heating wires. Thus, the working tube is part of the furnace

heating which has the advantage that the furnaces achieve very high heat-up

rates. The tube furnaces can be supplied for 1100 °C or 1300 °C. Both models

are designed for horizontal application. If the customer requires protective

gas atmosphere, a separate working tube incl. gas supply system 1, e.g. made of

quartz glass, must be inserted in the working tube.

- Tmax 1100 °C or

1300 °C

- Dual shell housing

made of sheets of textured stainless steel

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Inner diameter of

the tube: 30 mm, heated length: 200 mm

- Working tube made

of C 530 material including two fiber plugs as standard

- Thermocouple type K

(1100 °C) or type S (1300 °C)

- Solid state relays

provide for low-noise operation of the heating

- Heating wires wound

directly around the working tube resulting in very fast heat-up rates

- Defined application

within the constraints of the operating instructions

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Gas supply system

for non-flammable protective or reactive gas

Available Model Number :

RD 30/200/11, RD 30/200/13

|

|

| Tube furnace R 170/1000/13 |

Tube furnace R 50/250/13 with gas supply system 2 |

These compact tube furnaces with integrated control systems can

be used universally for many processes. Equipped with a standard working tube

of C 530 ceramic and two fiber plugs, these tube furnaces have an

unbeatable price/performance ratio.

- Tmax 1200 °C or

1300 °C

- Single-zoned design

as standard

- Dual shell housing

made of sheets of textured stainless steel

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Outer tube diameter

of 50 mm to 170 mm, heated length from 250 mm to 1000 mm

- Working tube of C

530 ceramic including two fiber plugs as standard equipment

- Tmax 1200 °C: Type

N thermocouple

- Tmax 1300 °C: Type

S thermocouple

- Solid state relays

provide for lownoise operation

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Charge control with

temperature measurement in the working tube and in the furnace chamber

outside the tube

- Three-zoned design

(heated length from 500 mm)

- Gas supply systems

for protective gas or vacuum operation

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available Model Number :

R 50/250/12, R 50/500/12, R 120/500/12, R 170/750/12, R

170/1000/12, R 50/250/13, R 50/500/13, R 120/500/13, R 170/750/13, R

170/1000/13

Tube Furnaces with Stand for

Horizontal or Vertical Operation

|

|

|

|

Tube furnace RT 50-250/11

|

Tube furnace RT 50-250/13

|

These

compact tube furnaces are used when laboratory experiments must be performed horizontally,

vertically, or at specific angles. The ability to configure the angle of tilt

and the working height, and their compact design, also make these tube furnaces

suitable for integration into existing process systems.

- Tmax 1100 °C, 1300

°C, or 1500 °C

- Compact design

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Vertical or

horizontal operation freely adjustable

- Working height

freely adjustable

- Working tube made

of C 530 ceramic

- Type S thermocouple

- Operation also

possible separate from stand if safety guidelines are observed

- Control system

integrated in furnace base

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Available Model Number :

RT 50-250/11 , RT 50-250/13, RT

30-200/15

High-Temperature Tube Furnaces with

SiC Rod Heating Gas Atmosphere or Vacuum

|

|

| Tube furnace RHTC 80-230/15 with manual gas supply system |

Tube furnace RHTC 80-450/15 |

SiC rod

heating

These compact tube furnaces with SiC rod heating and integrated

switchgear and controller can be used universally for many processes. With an

easy to replace working tube as well as additional standard equipment options,

these furnaces are flexible and can be used for a wide range of applications.

The high-quality fiber insulation ensures fast heating and cooling times. The

SiC heating rods installed parallel to the working tube ensure excellent

temperature uniformity. The price-performance ratio for this temperature range

is unbeatable.

- Tmax 1500 °C

- Dual shell housing

made of sheets of textured stainless steel

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Active cooling of

housing for low surface temperatures

- Type S thermocouple

- Solid state relays

provide for low-noise operation

- Prepared for

assembly of working tubes with water-cooled flanges

- Ceramic tube, C 799

quality

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load

- Charge control with

temperature measurement in the working tube and in the furnace chamber

outside the tube

- Fiber plugs

- Check valve at gas

outlet avoids intrusion of false air

- Working tubes for

operation with water-cooled flanges

- Display of inner

tube temperature with additional thermocouple

- Alternative gas

supply systems for protective gas or vacuum operation

- Process control and

documentation via VCD software package for monitoring, documentation and

control

Available Model Number :

RHTC 80-230/15, RHTC 80-450/15, RHTC 80-710/15

High-Temperature Tube Furnaces for

Horizontal and Vertical Operation up to 1800 °C Gas Atmosphere or Vacuum

|

|

| Tube furnace RHTH 120/600/17 |

Tube furnace RHTV 120/480/16 LBS with working tube closed at

one side, protective gas and vacuum option as well as with electric screw

drive of the lift table |

RHTV

50/150/17 vertical tube furnace with stand and gas supply system 2 as additional

equipment

Tube

furnace RHTH 120/600/18

The high-temperature tube furnaces are available in either

horizontal (type RHTH) or vertical (type RHTV) designs. High-quality insulation

materials made of vacuum-formed fiber plates enable energy-saving operation and

a fast heating time due to low heat storage and heat conductivity. By using

different gas supply systems, operations can be performed under non-flammable

or flammable protective or reactive gases or under vacuum.

- Tmax 1600 °C, 1700

°C, or 1800 °C

- MoSi2 heating

elements, mounted vertically for easy replacement

- Insulation with

vacuum-formed ceramic fiber plates

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Rectangular outer

housing with slots for convection cooling

- Tube furnaces RHTV

with frame for vertical operation

- Dual shell housing

made of sheets of textured stainless steel

- Ceramic working

tube made of material C 799 incl. fiber plugs for operation under air

- Type B thermocouple

- Power unit with

low-voltage transformer and thyristor

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2

in accordance with EN 60519-2 as temperature limiter to protect the

furnace and load and with selectable maximum temperature gradient as tube

protection

- Switchgear and

control unit separate from furnace in separate floor standing cabinet

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Charge control with

temperature measurement in the working tube and in the furnace chamber

outside the tube

- Display of inner

tube temperature with additional thermocouple

- Gas tight flanges

for protective gas and vacuum operation

- Manual or automatic

gas supply system

- Three-zone control

for optimization of temperature uniformity (only tube furnaces RHTH)

- Check valve at gas

outlet avoids intrusion of false air

- Process control and

documentation via VCD software package or Nabertherm Control Center (NCC)

for monitoring, documentation and control

Available Model Number ;

Horizontal

design : RHTH 50/150/.., RHTH 80/300/.., RHTH

120/600/.

Vertical

design : RHTV 50/150/.., RHTV 80/300/.., RHTV 120/600/..

Horizontal or Vertical Operation up

to 1300 °C Gas Atmosphere or Vacuum

|

|

| Tube furnace RSV 170/1000/11 with gas supply system 2 |

Tube furnace RSH 80/500/13 with gas tight tube and

water-cooled flanges |

Tube

furnace RS 120/750/13 with gas supply system 4, hydrogen applications

Quartz

glass and flanges for protective gas operation as optional equipment

Tube

furnace RSH 120/1000/11S, three-zone controlled, incl. zone separators to reach

a temperature gradient

Tube furnace

RSH 50/500/13

These tube furnaces can be used for horizontal (RSH) or vertical

(RSV) operation. The split-type design makes it easy to change the working

tube. It allows for a comfortable exchange of various working tubes (e.g.

working tubes made of different materials).

Using the wide range of accessories these professional tube

furnaces can be optimally tailored to your process. By upgrading the furnaces

with different gas supply systems the operation in a protective gas atmosphere,

under vacuum or under flammable protective or reactive gases is possible.

Besides convenient standard controllers for process control modern PLC control

systems are also available.

- Tmax 1100 °C or

1300 °C

- Dual shell housing

made of sheets of textured stainless steel

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Tmax 1100 °C: Type

N thermocouple

- Tmax 1300 °C: Type

S thermocouple

- Frame for vertical

operation (RSV)

- Split-type design

for simple insertion of the working tube

- Working tube made

of material C 530 incl. fiber plugs for operation under air in scope of

delivery

- Heating elements on

support tubes provide for free radiation

- RSV: switchgear and

control unit separate from furnace in own wall or standing cabinet

- RSH: switchgear and

control unit integrated in furnace housing

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Charge control with

temperature measurement in the working tube and in the furnace chamber

outside the tube

- Display of inner

tube temperature with additional thermocouple

- Different gas

supply systems for non-flammable or flammable protective or reactive gases

and vacuum operation

- Three-zone control

for optimization of temperature uniformity

- Cooling systems for

accelerated cooling of the working tube and charge

- Check valve at gas

outlet avoids intrusion of false air

- Base frame with

integrated switchgear and controller

- Process control and

documentation via VCD software package or Nabertherm Control Center (NCC)

for monitoring, documentation and control

Available

Model Number ; RSH 50/250/.., RSH 50/500/.., RSH 80/500/.., RSH 80/750/.., RSH 120/500/.,

RSH 120/750/., RSH 120/1000/, RSH 170/750/, RSH 170/1000/, RSV

50/250/.., RSV 50/500/., RSV 80/500/.., RSV 80/750/., RSV 120/500/, RSV

120/750/., RSV 120/1000/., RSV 170/750/.., RSV 170/1000/.

Rotary

Tube Furnaces for Batch Operation up to 1100 °C

|

|

| Rotary tube furnace RSRB 80/500/11 as tabletop version for

batch operation |

Rotary tube furnace RSRB 120/500/11 |

Rotary

tube furnace tilted towards the right side for charging and batch operation

Rotary

tube furnace tilted towards the left side to discharge

Connection

set for vacuum operation

Gas tight

closing plug for tubes made of quartz glass closed at one side

The rotary tube furnaces of the RSRB series are ideally suited

for batch operation. The permanent rotation of the working tube ensures that

the charge is constantly in motion. Due to the special shape of the quartz

reactor with the tapered pipe ends the batch is kept in the rotary tube furnace

and can be heat-treated an arbitrarily long time period time; a controlled

heating to the temperature profiles is also possible.

- Tmax 1100 °C

- Thermocouple type K

- Dual shell housing

made of sheets of textured stainless steel

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Tube furnace

designed as table-top model with quartz glass reactor which opens on both

sides, tapered ends

- Reactor is removed

for emptying out of the rotary tube furnace. Beltless drive and hinged

furnace housing (opening temperature < 180 °C) provide for very easy

removal through

- Adjustable drive of

approx. 2-45 rpm

- Switchgear and

control unit separate from tube furnace in own wall or standing cabinet

- Defined application

within the constraints of the operating instructions

- NTLog Basic for

Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

- Three-zone control

for the optimization of temperature uniformity

- Temperature display

unit in the working tube with measurement by means of an additional

thermocouple

- Charge control by

means of an additional thermocouple in the working tube

- Different gassing

ensures good flushing of the charge with process gas through inlet on one

side and outlet on other side of tube

- Gas-tight rotary

feedthrough for connection of the rotating reactor to a gas supply system

- Check valve at gas

outlet avoids intrusion of false air

- Vacuum design, up

to 10-2 mbar depending on

the applied pump

- Open on both sides

reactor made of quartz glass with knobs for better mixing of the charge in

the tube

- Package for

improved charging and discharging of the working tube in the following

design:

- Mixing reactor

made of quartz glass with integrated blade for better mixing of the

batch, closed on one side, large opening on the other side

- Tilting mechanism

to the left/to the right. For charging and heat treatment, the furnace is

tilted towards the right side until the stop so that the load is charged

into the rotary tube furnace. For discharge, the furnace is tilted

towards the other side to discharge the powder from the reactor. It is no

longer necessary to remove the reactor.

- Rotary tube

furnace assembled on base with integrated switchgear and controller,

incl. transport casters

- Process control and

documentation via VCD software package or Nabertherm Control Center (NCC)

for monitoring, documentation and control

Available Model Number:

RSRB 80-500/11, RSRB 80-750/11, RSRB 120-500/11, RSRB 120-750/11, RSRB

120-1000/11

Rotary Tube Furnaces for Continuous

Processes up to 1300 °C

|

|

| Rotary tube furnace RSRC 80/500/11 for processes under

protective gas or in vacuum |

Rotary tube furnace RSRC 120/750/13 |

Screw-conveyor

with adjustable speed

Screw-conveyors

with different pitches for the adaption to the charge

Vibrating

channel on the rotary tube for convenient material feeding

Vibration

generator at the charging funnel for improved powder supply

The RSRC rotary tube furnaces are particularly suitable for

processes where continuously running batch material is heated for a short time.

The rotary tube furnace is positioned slightly inclined

heated-up to the target temperature. The material is then continuously supplied

at the upper end of the tube. It passes through the heated area of the tube and

falls on the lower end out of the tube. The time of heat treatment results from

the inclination angle, the rotational speed and the length of the working tube,

as well as from the flow properties of the batch material.

Equipped with the optional closed loading system for 5 liter

charge material incl. receptacle, the rotary tube furnace can also be used for

processes under protective gas or vacuum.

Depending

on process, charge and required maximum temperature, different working tubes

made of quartz glass, ceramics or metal are used (see page 50). This rotary

tube furnace is therefore highly adaptable for different processes.

- Tmax 1100 °C

- Working tube made

of quartz glass open at both sides

- Thermocouple type

K

- Tmax 1300 °C

- Open tube made of

ceramics C 530

- Thermocouple type

S

- Heating elements on

support tubes provide for free radiation

- Dual shell housing

made of sheets of textured stainless steel

- Only fiber

materials are used which are not classified as carcinogenic according to

TRGS 905, class 1 or 2

- Adjustable drive of

approx. 2-45 rpm

- Digital display

unit for the tilting angle of the rotary tube furnace

- Beltless drive and

split-type furnace housing (opening temperature < 180 °C) provide for

very easy tube removal

- Compact system,

rotary tube furnace positioned on a base frame with

- Manual spindle

drive with crank to preset the tilting angle

- Switchgear and

controls integrated