Orange Photonics – ผู้ผลิตเครื่องมือวัด

เครื่องทดสอบสารสำคัญจากผลิตภัณฑ์ กัญชง กัญชา (Cannabis Analyzer Model LightLab 3) โดยใช้เทคนิค Liquid Chromatography แบบพกพา (Portable) สามารถทดสอบนอกสถานที่ (Onsite

Testing) เพื่อให้ได้ค่าที่แม่นยำ เพิ่มประสิทธิภาพและความสะดวกสบายในการวัด

ภายในระยะเวลาประมาณ 10.5 นาที สามารถวัดค่าองค์ประกอบสาร Cannabinoid ได้หลากหลายตามหมวดการวัด พร้อมฟังก์ชันการเชื่อมต่อ WIFI และรองรับการทำงานด้วยแบตเตอรี่

CANNABIS Analyzer mode LightLab

3 Modules

· Δ9-THC,

THC-A, CBD, CBD-A, CBN, CBG, CBG-A (Standard Module)

· CBN-A, CBC-A, CBC, Δ8-THC, Δ10-THC (Minor Module)

· Δ9-THC,

THC-A, Total THC (Hemp Compliance)

CANNABIS ANALYZER Model

LightLab 3

The accurate and easy-to-use LightLab 3 Cannabis Analyzer lets

non-technical users analyze cannabinoid content like a testing laboratory.

LightLab uses two common analytical methods, liquid chromatography and

spectroscopy, simplifying the process to make on-site testing affordable and

easy.

Standard

Cannabinoids

- Δ9-THC,

THC-A, CBD, CBD-A, CBN, CBG, CBG-A

Minors

Module

- CBN-A, CBC-A, CBC, Δ8-THC, Δ10-THC

Hemp

Compliance

Terpenes

Module

Features

- 0-100% Cannabinoid analysis

- Results in 10.5 minutes

- Easy sample preparation

- Portable, rugged

- WiFi enabled

- 8-hour battery life

Sample

Types

- Flower, Biomass, Young plant, Concentrates, Processed waste, Tinctures,

Infused products, Edibles (Contact us)

EASY TO USE

LightLab 3 provides lab-grade cannabinoid analysis in a rugged,

easy-to-use format. Its touchscreen streamlines and simplifies the entire

analytical process so every team member can follow the same workflow to produce

consistent results.

- Step-by-step –

On-screen instructions guide you through each step of the sample

preparation process based upon the sample type you select.

- Accessories –

Your LightLab includes all the accessories you need to begin using

LightLab right out of the box, including a scale, sample shaker and more.

- Tags – You

have the option to include information about your sample including the

operator’s name, sample ID etc. Each test result will automatically

include date, time etc.

- Factory Calibration – LightLab

arrives pre-calibrated and ready-to-use right out of the box. LightLab

calibrations use Certified Reference Standards for traceability.

- Mobile Monitoring – LightLab’s

Mobile Monitoring feature gives users the ability to remotely track

testing progress from start to finish from a smartphone.

- Results –

The results from your most recent tests, as well as previous tests, may be

viewed on the screen, exported as a CSV file and shared via text or email

directly from LightLab.

- Pro Mode –

Advanced technical LightLab users may bypass guided screens to streamline

workflow in Pro Mode and access chromatograms.

- Workbench Setup – If

you run a high volume of tests from stationary workstation, a Workbench

Setup will let you run more tests at a lower cost-per-test.

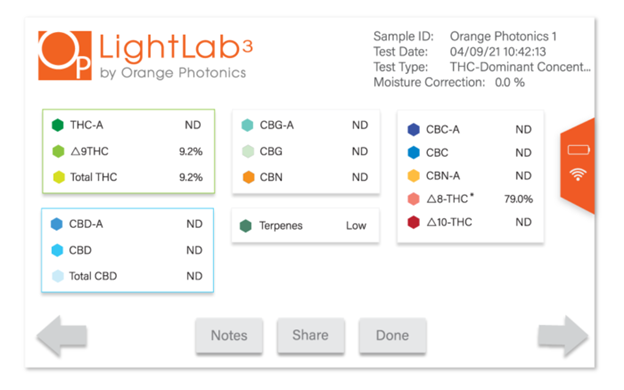

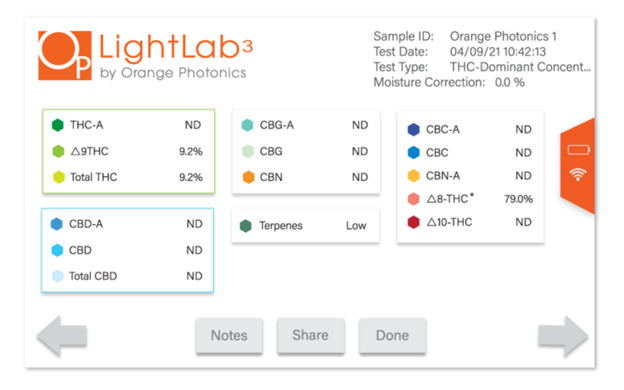

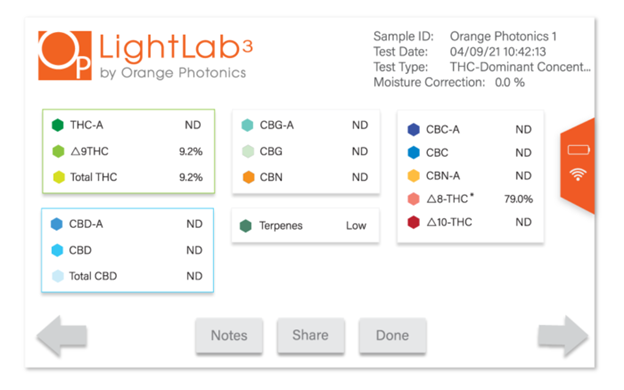

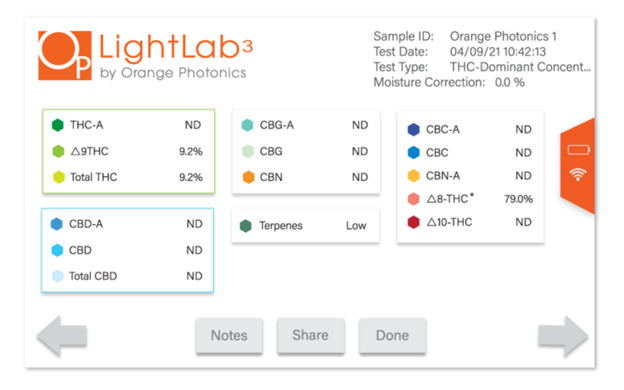

RESULTS

Sample analysis results are available in five formats.

1. On-screen –

After you run your sample, your results will populate on LightLab’s screen.

From this screen you can add additional details about the sample by tapping

“notes” or you can tap “done” and run your next sample. You may also scroll

through your test history to compare results.

2. Spreadsheet

– LightLab provides a results spreadsheet (CSV) which gives you

maximum flexibility and the opportunity to further analyze sample results in

aggregate.

3. Report –

You can use the CSV file to generate a full report, containing all the details

about the sample you ran, including all inputted information such as moisture

correction, operator, sample size and more.

4. Text

and email – Once your LightLab is set-up on your Wi-Fi, you can share your

results via text or email.

5. Mobile

Monitoring – Get an instant notification when your test results are ready;

view and share those results straight from your smartphone.

LightLab

3 results screen, all current modules shown.

Orange Photonics LightLab Brochure

LightLab 3 may be customized to meet your testing needs.

LightLab’s standard configuration can report seven cannabinoids and additional

modules can add greater capabilities to your LightLab.

Compounds

- Δ9-THC,

THC-A, Total Potential THC

Product

- Flower, Biomass, LOD 0.05%

Users

- Cultivators, Processors, Regulators

Compounds

- Semi-quantitative, Low, medium, high

Product

- Flower, Concentrates, Infused

Users

Compounds

- CBN-A, CBC, CBC-A, Δ8-THC, Δ10-THC

Product

- Flower, Concentrates, Infused

Users

- Cultivators, Processors, Breeders

HEMP COMPLIANCE MODULE

On-site THC compliance testing has never been easier.

LightLab’s Hemp Compliance Module takes

the guess work out of crop monitoring delivering THC-A, D9-THC and Total

Potential THC content between .05% and 3% with high precision. The additional

capabilities, combined with LightLab’s cannabinoid panel tests, will allow you

to get a complete picture of your crop’s cannabinoid production with real-time

data.

- Monitor CBD/THC ratios

- Harvest at peak

- Schedule Department of Ag visits at the right time

- Verify Certificates of Analysis

- Evaluate biomass

Learn more about the

Hemp Compliance Module here

TERPENES MODULE

Terpene molecules are responsible for the scent profiles of

cannabis plants and products. They offer an indication of freshness, they

impact the consumption experience, guide consumer preference and support

product differentiation.

With the Terpenes Module, LightLab can

analyze the richness of the sample’s terpene content without any changes in

sample preparation or hardware upgrade.

Semi-Quantitative Analysis

Over 100 cannabis terpenes have been identified to date and those

terpenes generally fall into two categories: monoterpenes and sesquiterpenes.

Monoterpenes comprise 80% of cannabis terpenes. LightLab can analyze and

quantify the monoterpenes present in a sample and uses that analysis to make an

assumption about the monoterpene-sesquiterpene ratio in the sample. LightLab

reports terpene content in samples as low, medium or high terpene content

offering a great first-line analysis that can help cultivators and processors

understand and value their product when terpene rich products are the end goal.

Low Terpene Range:

<1%

Medium Terpene Range: between 1% and 2%

High Terpene Range: >2%

No additional steps are required beyond the standard liquid

extraction used for LightLab cannabinoid analysis. In addition, no additional

analysis time is needed – LightLab calculates the terpene content at the same

time as cannabinoid analysis.

MINORS MODULE

By their very nature, minor cannabinoids are uncommon and can be a

valuable product differentiator. These minor cannabinoids in a plant or product

can be an indication of unique genetics, an opportunity for product

differentiation and measure of plant quality.

LightLab’s Minors Module analyzes the

following five cannabinoids:

- CBC-A: Cannabichromenic

Acid. CBC-A is the acidic form of CBC. It is non-psychoactive

and is formed in some plant genetics alongside THC-A and CBD-A, typically

at lower concentration. It’s a precursor is CBG-A. Some

genetics will exhibit 1-5% CBC-A.

- CBC: Cannabichromene.

CBC is the neutral form of CBC-A. CBC is often present in hemp and

CBD containing plants, and more rarely in THC containing plants. Since

many laboratories do not yet measure CBC, the Minors Module will allow

hemp farmers, CBD growers and processors to select for higher CBC plants

and differentiate their product with a new cannabinoid.

- CBN-A: Cannabinolic

Acid. CBN-A is the acidic form of CBN. It is often formed from

aged cannabis plants. Very old plants may contain 0-5% CBNA.

CBN-A in combination with CBN are good indicators of the age and storage

conditions of plant material. Higher CBN-A and CBN typically

indicates old plant material or poorly stored plant material.

- Δ8-THC: Delta-8-Tetrahydrocannabinol. Δ8-THC

is generally made by converting CBD or Δ9-THC in a chemical reaction. Note that the process used to

create Δ8-THC

often creates other cannabinoids, including Δ9-THC. When running a Δ8-THC sample, LightLab

has a higher detection limit of 4% for flower samples and 12% for

concentrates.

- Δ10-THC: Degraded

THC, Dihydroxy-THC. In some cases, distillation can breakdown the THC

molecule into by-products, reducing the potency of the product and

affecting the taste. Two of the major breakdown components are CBN

and Δ10-THC.

LightLab can measure the amount of Δ10-THC, allowing distillation operators to ensure their

product is pure and potent while maintaining high throughput. In

some cases, extraction operators will intentionally attempt to generate

novel cannabinoids through a degradation process. Δ10-THC is a precursor

to most of the degradation products generated.

HOW IT WORKS

Built

for Cannabis. Built for Performance.

LightLab was designed to be easy-to-use and deliver lab-grade

accuracy. LightLab applies liquid chromatography which separates the

cannabinoids, spectroscopy which uses light to analyze the sample’s compounds

and linear regression mathematics to calculate sample results.

HIGH PERFORMANCE LIQUID CHROMATOGRAPHY

Your analytical laboratory likely uses High Performance Liquid

Chromatography (HPLC) to analyze your hemp or cannabis sample. Like an HPLC,

LightLab pushes an extracted cannabis sample through a column. The column

separates the cannabinoids in the sample by slowing down cannabinoids by

different amounts based on their affinity to the column. This allows each

cannabinoid to exit the column at a different time. For example, CBD may exit

the column first, then D9THC and so on. Once the column separates the cannabinoids,

they move to the next step in the analytical process: spectroscopy.

ULTRAVIOLET SPECTROSCOPY

Spectroscopy uses light to measure the analytical composition of

compounds. During the analytical process the sample flows between a light

source and a detector. The detector will quantify how much light is getting

through the sample. Since every cannabinoid has a particular light absorption

signature LightLab can provide quantitative measurements. LightLab

borrows spectroscopy technology from the Curiosity

Mars Rover, providing an accurate and dependable analysis every time.

LIGHTLAB CHROMATOGRAM AND CALCULATIONS

When LightLab analyzes a sample, it separates cannabinoids over

time and detects them with UV light at several wavelengths. An HPLC works in

much of the same way, though in many cases only one wavelength of light is

utilized. In a standard HPLC, the chromatogram shows peaks that represent

different analytes; the area of the analyte is correlated with the

concentration of that analyte. While LightLab uses the chromatogram as part of

its analysis, the calculation is not a strict peak area calculation. Instead,

LightLab uses a sophisticated multi-dimensional, non-linear regression to

calculate results. This algorithm uses multiple UV wavelengths along with the

chromatogram to determine the final results. This allows for a more robust and

accurate measurement of cannabinoids even with challenging environmental

conditions and complex samples.

RESULTs

Track.

Share. Compare.

It has never been easier to track, share and manage your test

data. Track test progress from your mobile device, share test results, and

generate a Certificate of Analysis complete with authenticity verification

controls.

Click image and scan QR code to reveal Result Dashboard

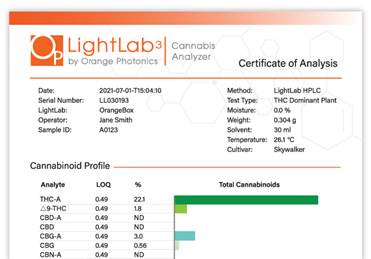

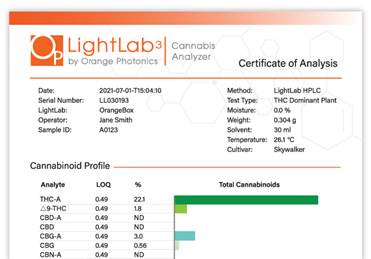

CERTIFICATE OF ANALYSIS

Generate a Certificate of Analysis (CoA) with the click of a

button. The CoA reports the cannabinoid content of the sample in weight

percent, limits of detection, user inputted sample identifiers, and

automatically generated information such as time stamp and instrument serial

number. A QR code on the report corresponds with the original test results and

confirms the authenticity of the report itself.

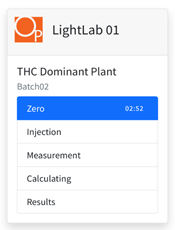

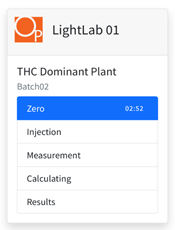

MOBILE MONITORING

LightLab’s Mobile Monitoring feature gives users the ability to

remotely track sample test progress, start to finish from a smartphone. This

gives users the ability to step away from their LightLab and tend to other

tasks while running a test. LightLab sends notifications when the next step of

the testing process is ready and redirects to the Result Dashboard when

the test is complete.

RESULT DASHBOARD

When a test is complete, a unique QR code is generated that brings

you to a Result Dashboard, populated through an internet webpage. The Result

Dashboard displays sample details and final results. From this page you can

share your data to your social media pages or contacts, generate an official

Certificate of Analysis, and download a CSV report.

RESULTS

Sample analysis results are available in five formats.

1. On-screen –

After you run a sample, the results will populate on the LightLab. From this

screen you can add additional details about the sample by tapping “Notes,” tap

“Done” to run your next sample, or select “Share” to share your results via

email or text. The share feature has two options for sending results; send the

Certificate of Analysis or choose to send the Result Dashboard.

2. Certificate of Analysis –

An official Certificate of Analysis (CoA) which includes user inputted sample

identifiers and final results.

3. Result Dashboard –

The Result Dashboard is a unique webpage displaying sample

details and final results. From this page you can generate an official

Certificate of Analysis, download a CSV report, and share sample details.

4. Report –

You can use the CSV file to generate a full report containing the details about

the sample you ran, including all inputted information such as moisture

correction, operator, sample size and more.

5. Text

and Email – Once your LightLab is set-up on Wi-Fi, you can share your

results via text or email. Sharing capabilities include an official Certificate

of Analysis or the Results Webpage.

CALIBRATION

District

Derp’s Co-Owner, Chris, running samples on LightLab. Look for District Derp on

social media to learn about their cutting-edge operation.

LightLab 3 is shipped to you calibrated and ready to run. After

you have run 1,000 tests or after one year, whichever comes first, return your

LightLab to Orange Photonics for a calibration service. LightLab calibrations

use Certified Reference Standards.

The only hands-on maintenance required is the easy task of

replacing the Selective Separation Column every 25 tests. LightLab runs a

self-cleaning cycle automatically and therefore it does not require manual

cleaning or flushing.

LIGHTLAB OPERATING EXPENSE

Like all lab-based liquid chromatography instrumentation, LightLab

uses solvent to extract the cannabinoids from the sample. The same LightLab

Extraction Solvent is also used as a carrier solution (mobile phase). LightLab

Plant or Concentrate Test Kits include everything you need to run a sample in

one economic package that includes vials, syringes, solvents, filters and Selective

Separation Columns. Cost per test varies depending on the volume of tests

required, but typically fall in the $3-5 price range.

LIGHTLAB WARRANTY

Your LightLab Cannabis Analyzer comes with a standard one-year

factory warranty. An extended 2-year warranty option with calibration service

is available.