|

เครื่องมือทดสอบคุณสมบัติน้ำมันหล่อลื่น (LUBRICANT TESTERS)

|

| Four Ball Tester – ASTM D2783, D2596, D2266, D4172, D5183 |

|

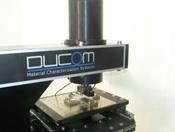

The Ducom’s Four Ball Tester TR 30 family is designed to determine wear preventive (WP), extreme pressure (EP), frictional fatigue and shear stability behavior of oils and greases.

Compliance with ASTM D2783, D2596, D2266, D4172, D5183, CEC L-45-T93 (optional), DIN 51359-6 (optional), IP 239 and IP 300 (optional).A rotating steel ball is pressed against three steel balls firmly held together and immersed in lubricant. Test load, duration, temperature and rotational speed are set in accordance with standard test schedule.

-WP tests: average scar diameter of the stationary ball is reported.

-EP tests: the load is increased after every run of the spindle until the contact fails.

-Rolling contact fatigue failure is indicated by increase of vibration.

-Shear stability is determined with a tapered rolling bearing.

main characteristics

- Measurement of actual load, rotational speed and temperature

- Frictional force is recorded live during the test

- Coefficient of friction is displayed online

- Scar diameter can be measured with an optical microscope

- An image acquisition system acquires the image of the scar on the PC

|

|

| Timken OK Load Tester – ASTM D2509 & 2782 |

|

The Ducom Timken OK Load Tester uses a steel bearing race pressed against a steel block creating a line contact, recreating many real life tribological contacts. Grease is poured into the contact area and the load is increased until the lubricant film is broken.

Application

Evaluation of extreme pressure properties and COF of lubricants

Standards

ASTM D2608, D2782, IP326, IP 240

Test Variables

|

|

| Pin on Vee Block Tester – ASTM D2625, D2670, D3233, D5620 |

|

Application

Extreme pressure and Wear Preventive performance evaluation of Lubricating Oils, Grease and Solid Lubricants.

Standards

ASTM D5620, D2625, D2670, D3233, IP241

Test parameters

- Load

- Rotational speed

- Temperature

- Test duration

- Frıctıonal Torque

|

|

| Reichert Tester |

|

|

For evaluation of (WP) and (EP) properties of lubricants and additives. Quick method to detect the formation of lubricating film between two test surface. A drop in noise level (screeching) to identify when a lubricating film is successfully formed.

– Significant utilization to evaluate and rank of products

– Very useful for additive depletion studies and lubricant selection for metallurgy

– Effective tool to determine lubricant quality while in use in machinery

– This tester is capable of testing both lubricating oils and greases

– Ducom incorporates instrumentation to monitor and log noise level |

|

| Low Temperature Torque Tester – ASTM D1478 |

|

Application

To detect the tendency of various greases to resistance to the rotation of bearing at negative degrees Celsius. Mainly for aerospace applications and equipment in sub zero environment.

– On line measurements of torque and temperature

– Liquid Nitrogen to cool sample to test temperature

– PID controlled test temperature

– Software to record and display on PC

Standards Test Variables

ASTM D 1478 Load

Torque

Temperature |

|

| High Temperature Grease Tester – ASTM D3336 |

|

|

Purpose

Evaluation of lubricants at high speeds, high temperatures and low loads

Standards

ASTM D 3336

Test Variables

Load

Temperature

Test Duration |

|

| Shear Stability Tester – ASTM D6278, IP234 |

|

Application

To evaluate the shear stability of polymer- containing oils in terms of the permanent viscosity loss when a sample is mechanically stressed.

Method of Testing

The test fluid is mechanically stressed by pumping through a diesel injector nozzle and a diesel Injection fuel pump.

Samples are taken after the fluid has completed a predetermined number of passes.

Viscosities of the original sample and of samples taken during the test are determined.

The extent of oil degradation due to shear forces can be calculated.

Standard

ASTM D 6278, IP 234 |

|

|

|

|

|

|

เครื่องทดสอบการสึกหรอของชิ้นส่วนเครื่องจักรโลหะ (TRIBOMETERS)

|

| Abrasion Tester (Dry and Slurry) – ASTM G65, G105, B611 |

|

The Ducom Abrasion Tester is very versatile, offering a wide operating range with excellent control over test parameters.

Test Standards

ASTM G65 – Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

ASTM G105 – Standard Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests

ASTM B611 – Standard Test Method for Determining the High Stress Abrasion Resistance of Hard Material

|

|

| Rotary Tribometer – Pin/Ball on Disk – ASTM G99 |

|

Description

The Ducom Rotary Tribometer comprises of a precision controlled drive that controls disc rotation. The counter specimen – which may be a ball, pin or any other custom geometry – is held firmly in a friction/loading arm. A known load is applied upon the counter specimen to achieve the desired contact stress.

The Rotary Tribometer is a fully computer controlled test system. Operator may choose and set the desired test parameters from the Ducom TriboAcquire control and data acquisition system. The test parameters are displayed and output is recorded.

Applications

- Evaluation of wear resistance of bio-materials

- Wear and Friction properties of thin films and coatings .

- Tribological tests on polymers, soft materials and coatings in lubricated, lubricated and corrosive conditions.

- Determination of working load limit of soft coatings like PTFE and other polymers.

- Product development and quality control of surface engineered products

Test Standards: ASTM G99

|

|

| Linear Reciprocating Tribometer (LRT)-HFRR ASTM D6079, G133, CEC F-60-A-96 |

|

DUCOM LINEAR RECIPROCATING TRIBOMETER SET UP FOR LUBRICANT ADDITIVE TESTING Materials and lubricants are often subjected to repeated back and forth (reciprocating) movement, in many real applications, from automotive to biotribological environments.

High variety of sample geometries available in order to study:

- Point contact / Line contact / Area contact

Test Standards: ASTM D6079, G133, CEC F-60-A-96

|

|

| Gas Jet Erosion Tester – ASTM G76 |

|

Principle of operation

The Ducom Air Jet Erosion Tester is designed to impinge test samples with controlled flux of erodent. The test system is versatile and allows users to control impingement velocity , impingement angle, erodent flux and temperature. The result of the test is reported as the loss of weight of the sample. It may be converted to volume loss for comparative ranking of materials.

Features

- Erodent flux rate control

- High temperature test options

- Double disc velocity meter

- Easy changing of samples

- Easy replacement of nozzles

- Easy machine operation

Test Standards: ASTM G76

|

|

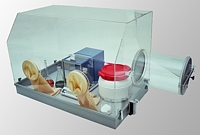

| Slurry Jet Erosion Tester |

|

Introduction

A rectangular sample under evaluation is made to rotate in a slurry cup. The sample is weighed before and after the test to determine loss of mass due to slurry erosion. Volume loss is computed for comparison, due to difference in densities of materials. Index of erosion is reported as loss of volume.

The test rig permits running up to 6 test samples at the same time and same speed. Slurry cups are immersed in water bath to maintain slurry temperature. Test duration can be preset with timer.

Features

- Preset revolution count / duration of test.

- Heating/cooling fluid circulation jacket.

- Up to six different samples tested together.

|

|

| Slurry Pot Erosion Tester |

|

Introduction

A rectangular sample under evaluation is made to rotate in a slurry cup. The sample is weighed before and after the test to determine loss of mass due to slurry erosion. Volume loss is computed for comparison, due to difference in densities of materials. Index of erosion is reported as loss of volume.

The test rig permits running up to 6 test samples at the same time and same speed. Slurry cups are immersed in water bath to maintain slurry temperature. Test duration can be preset with timer.

Features

- Preset revolution count / duration of test.

- Heating/cooling fluid circulation jacket.

- Up to six different samples tested together.

|

|

| Roller on Roller Tribometer |

|

The Roller on Roller Tribometer is intended for friction and wear evaluations of materials and lubricants that operating under roll and slide conditions as seen in gears, rail roads and other such applications. With two servo con-trolled drives, this system is capable of performing tribological tests in pure sliding to rolling contact tests.

- Users can define the percentage of slip and roll

- Precise control over speeds and directions

- Fully automatic computer controlled

- Continuously variable speed

- Options for automated loading and temperature control

|

|

| Multi Mode TribometerADVANCED MULTI CAPABILITY TRIBOMETER – ASTM G99,G133, G77, D3702, D5183, D2266, D4172, DIN50324 |

|

By choosing appropriate configurations, some or many of the following test standards may be possible on your Ducom Multi Mode Tribometer.

- ASTM G99 – Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

- ASTM G133 – Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear

- ASTM G77 – Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test

- ASTM D3702 – Standard Test Method for Wear Rate and Coefficient of Friction of Materials in Self-Lubricated Rubbing Contact Using a Thrust Washer Testing Machine

- ASTM D5183 – Standard Test Method for Determination of the Coefficient of Friction of Lubricants Using the Four-Ball Wear Test Machine

- ASTM D2266 – Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method)

- ASTM D4172 – Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method)

- DIN 50324 – Tribologie; Prüfung von Reibung und Verschleiß; Modellversuche bei Festkörpergleitreibung (Kugel-Scheibe-Prüfsystem) / Tribology; testing of friction and wear model test for sliding friction of solids (ball-on-disc system)

|

|

| NEW │ Hot Forming TribometerRAPID ELEVATED TEMPERATURE TESTING |

|

Process of hot forming is performed under severe conditions of pressure and temperature at tool contact. Surface of tool in contact with job suffers wear due to flow of hot metal. Estimation of tool life requires friction and wear data under realistic conditions.

High Temperature Tribometer is such an apparatus for physical analysis of sliding contacts and expansion of test strip under wide range of conditions.

- Metal Forming, High Speed Rolling and Drawing

- Metal Working

- Additive development

|

|

|

|

คุณสมบัติเชิงกลของเครื่องจักร (MECHANICAL TESTERS)

|

| Automated Indentation Tester |

|

Change in mechanical properties of materials during service reveals health and integrity of components. In case of critical component in service, it is not always possible to extract standard test specimen for laboratory test. In this situation, in-situ nondestructive testing on in service components is required and the Automated Indentation Tester is the instrument of choice in such cases.

- Ball Indentation (BI) test is in situ method of determination of aging related changes in material properties of components.

- Advanced design with software based operation, data acquisition and analysis

- Adaptors for field testing of pipes and bench testing of small samples.

- Ball impression is less than a mm in diameter, hence nearly a nondestructive test.

- Ideally suited for weld zone and HAZ as testing is localized.

- Strain or Stress controlled loading and unloading curve.

- Correction factor for indentation area to account pile-up/sink-in.

- One-click surface integrity assessment for time saving and comfort.

|

|

| Rotating Beam Tester (High Cycle Fatigue) – DIN 50113 |

|

Introduction

The purpose is to carry out rotating bar bending fatigue tests without deliberately introducing stress concentration in accordance with DIN 50113.

Description

A test piece mounted as a cantilever with single point loading is made to rotate and thus subjected to a bending moment. The force giving rise to the bending moment do not rotate.

Test Standards: DIN 50113

|

|

| UPDATED | Scratch Tester (V2.1)IMPROVED DESIGN AND EXTENDED CAPABILITIES (V2.1) |

|

Introduction

There is a growing trend towards the use of modified surfaces for improved performance and life of components. Modifications are invariably in the form of coatings on base material. They are deposited by electroplating, vapor phase deposition, diffusion, thermal spray or welding. Coatings need to be characterized for parameters like scratch resistance, critical load, adhesion and nature of damage under high stress. The Scratch Tester by Ducom facilitates these measurements over a wide range of parameters. |

|

|

|

|

|

|

เครื่องมือทดสอบคุณสมบัติของตลับลูกปืน (BEARING TESTERS)

|

| Journal Bearing Tester (Basic) |

|

Introduction

The Ducom Journal Bearing Tester (Basic) is designed to demonstrate and study pressure distribution behavior of lubricants in journal bearings.

Description

The system consists of a vertically mounted journal driven by a variable speed motor. The load is applied radially to the bearing with a loaded lever. Journal bearing assembly is immersed in lubricant. An electronic sensor measures the oil film pressure. The angular position of the pressure senor with respect to the load line is varied and pressure is recorded.

Pressure is plotted as a function of angular position of Cartesian or polar form to demonstrate the pressure distribution. Test variables are journal speed, radial load and lubricant viscosity. |

|

| Journal Bearing Tester (Advanced) |

|

Introduction

To study the hydrodynamic pressure distribution and heat dissipation during journal bearing lubrication . |

|

![]() Viscosity Standards น้ำยามาตรฐานสำหรับวัดค่าความหนืด

Viscosity Standards น้ำยามาตรฐานสำหรับวัดค่าความหนืด

![]()

![]() Sulfur Standards น้ำมันมาตรฐานสำหรับสอบเทียบกำมะถันในน้ำมันเตา ดีเซล หรือไอโซออกเทน เป็นต้น สำหรับการสร้างกราฟเครื่อง X-Ray Fluorescence (XRF)

Sulfur Standards น้ำมันมาตรฐานสำหรับสอบเทียบกำมะถันในน้ำมันเตา ดีเซล หรือไอโซออกเทน เป็นต้น สำหรับการสร้างกราฟเครื่อง X-Ray Fluorescence (XRF)![]() Sulfur Standards Flyer (PDF, 779KB)

Sulfur Standards Flyer (PDF, 779KB)

![]() Sulfur in Mineral Oil

Sulfur in Mineral Oil![]()

![]() Sulfur in Residual Oil

Sulfur in Residual Oil![]()

![]() Sulfur in Isooctane

Sulfur in Isooctane![]()

![]() Elements in Oil/Spectroscopy Products สารมาตรฐานปริมาณโลหะในน้ำมันรสำหรับสร้างกราฟเครื่อง AA, ICP, DCP, XRF, Rotrode เป็นต้น

Elements in Oil/Spectroscopy Products สารมาตรฐานปริมาณโลหะในน้ำมันรสำหรับสร้างกราฟเครื่อง AA, ICP, DCP, XRF, Rotrode เป็นต้น

![]() View Single Element standards Flyer (PDF – 345KB)

View Single Element standards Flyer (PDF – 345KB)![]()

![]() D-Series® Products สารมาตรฐาน D3, D12, D-19-0, D19

D-Series® Products สารมาตรฐาน D3, D12, D-19-0, D19

![]()

![]() Chlorine in Oil สารมาตรฐานคลอรีนในน้ำมัน

Chlorine in Oil สารมาตรฐานคลอรีนในน้ำมัน

![]()

![]() PremiSolv™ ICP Solvent ตัวทำละลายสำหรับการเตรียมสารมาตรฐานสำหรับเครื่อง ICP / น้ำมันสำหรับตัด Blank หรือค่าศูนย์ Base, Blank Oil และ Stabilizer เป็นต้น

PremiSolv™ ICP Solvent ตัวทำละลายสำหรับการเตรียมสารมาตรฐานสำหรับเครื่อง ICP / น้ำมันสำหรับตัด Blank หรือค่าศูนย์ Base, Blank Oil และ Stabilizer เป็นต้น

![]() View PremiSolv flyer (PDF)

View PremiSolv flyer (PDF)![]()

![]() PartiStan™ Automatic น้ำยาสอบเทียบขนาดอนุภาคตามมาตรฐาน ISO 11171

PartiStan™ Automatic น้ำยาสอบเทียบขนาดอนุภาคตามมาตรฐาน ISO 11171

![]()

![]() AA, ICP, XRF อะไหล่สิ้นเปลืองสำหรับ AA, ICP และ XRF เป็นต้น

AA, ICP, XRF อะไหล่สิ้นเปลืองสำหรับ AA, ICP และ XRF เป็นต้น

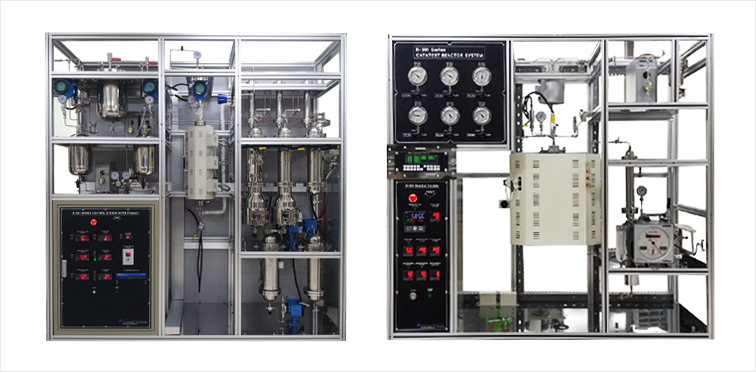

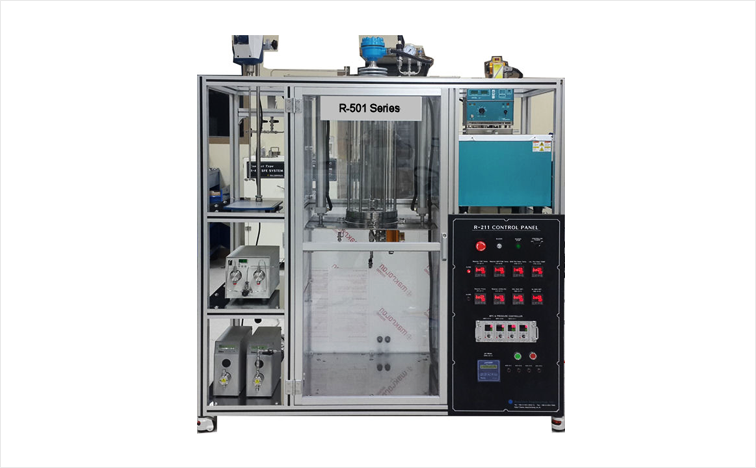

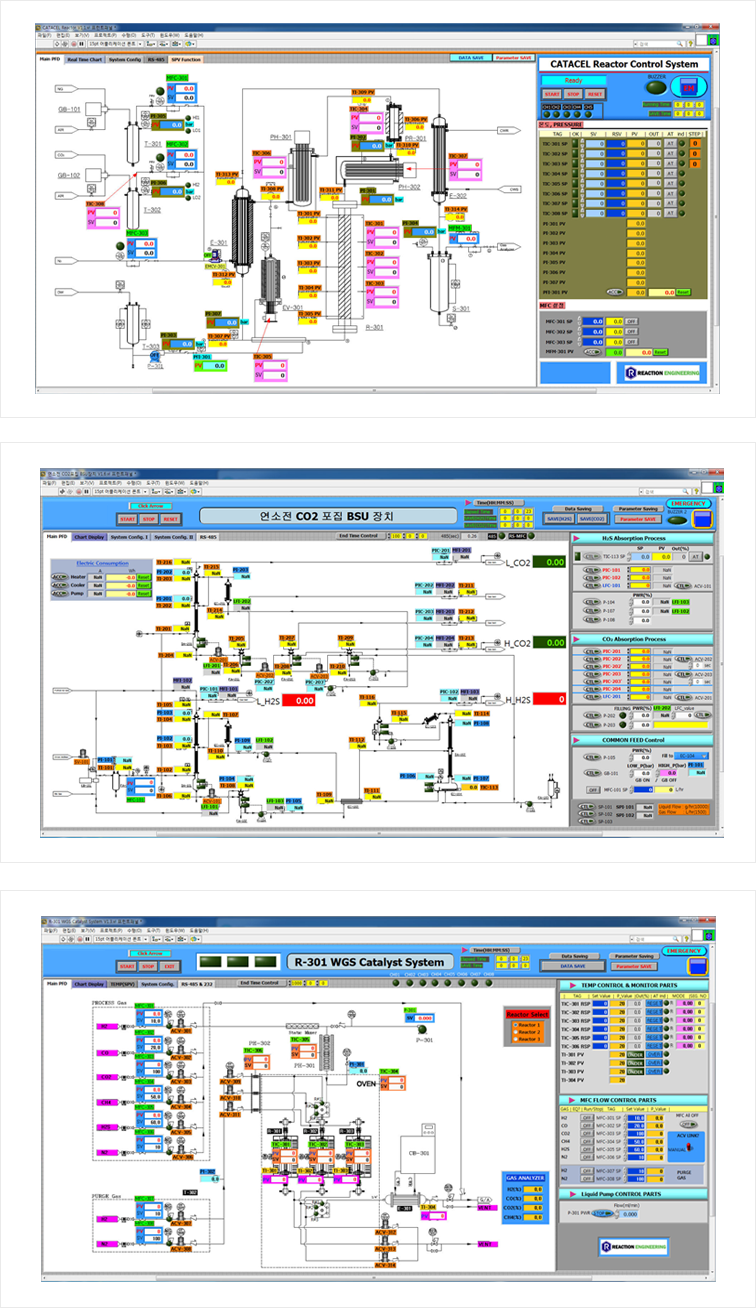

R-201 Series Reactor System

R-201 Series Reactor System

Pressure Vessel

Pressure Vessel