| เครื่องวัดความเร็วลมและอุณหภูมิ – Anemometers |

|

3650-3652 Traceable? Vane Anemometer Pens |

Three units provide for airflow/temperature; airflow/temperature/humidity/dew point, and airflow/temperature/humidity/dew point/barometric pressure. |

|

3655 Traceable? Micro-Anemometer/Therm. |

Ultra compact micro-design is small in size, and big in features |

|

4090 Traceable? Digital Anemometer |

Shows airflow in ft/min and m/s. Accuracy is 1%. Features include Min/ Max memory; hold function, and 2- or 16- sec. average. |

|

4091Traceable? Digital Anemometer with Therm |

Measures air velocity/temperature in hoods and outside environments. Displays even slight gas movement in ducts. |

|

4330 Traceable? Hot Wire Anemometer |

Probe extends in length for greater reach. Eliminates friction error caused by “moving parts” in wind vanes. Computer output. |

|

4331 Traceable? Anemometer/Thermometer |

Measures air velocity and temperature. Extra-large LCD. |

|

4332 Enviro-Meter? |

Provides in a single handheld package an anemometer, humidity meter, light meter and two thermometers. |

| เครื่องวัดค่าความดันบรรยากาศ อุณหภูมิ ความชื้นสัมพัทธ์ – Barometers |

|

1870 Traceable? Digital Barometer Module |

Altitude adjustment for exact barometric readings. Four-line LCD shows all current readings. |

|

4197,4195 Traceable?Compact Digital Barometer |

Measures atmospheric pressure, graphically displays the barometric trend, RH and temperature. |

|

4198 Traceable? Hand Held Digital Barometer |

eatures include altimeter, barometer, thermometer, stopwatch, and weather forecasting. |

|

4199 Traceable? Precision Dial Barometer |

Dial displays three scales: millibars, millimeters of mercury and inches of mercury. |

|

4245 Traceable? Workstation Digital Barometer |

Instantly displays, barometric pressure, trend graph, and temperature– Perfect for workstation or desktop. |

| เครื่องวัดค่าการนำไฟฟ้า และสารสอบเทียบ – Conductivity |

|

4063 Traceable? Conductivity Meter |

All in one conductivity meter. Temperature, Ohms, mhos, TDS, PPM, On/off Temperature compensation. |

|

4065-4270 Traceable? Conductivity Standards

|

16 ounce bottle, compatible with all meters. |

|

4070 Traceable? Conductivity Meter |

Computer and recorder output. Replatinizing current. |

|

4163 Traceable? Bench Conductivity Meter |

Computer and recorder output. Replatinizing current. |

|

4167 pH/Conductivity Univ. Flow-Thru Adaptor |

Universally designed. Constant monitoring. |

|

4168 Traceable? Pure Water Tester |

Easiest meter to operate. Tests reagent grade water. |

|

4169 Traceable? Dual-Display Conductivity |

Simultaneously displays conductivity and temperature readings. |

|

4170 Redi-Stor Probe Storage Solution |

Solution for storing conductivity probes. Insures probes respond instantly. |

|

4172-4271 Traceable?One Shot?Conductivity Sta |

Eliminates external contamination by performing calibration in a vial. |

|

4360 Expanded Range Conductivity Meter

|

Conductivity meter automatically selects the proper range and displays the exact answer without hassles. |

|

4365 Traceable? Cond./TDS/Salinity Meters |

Three units provide for conductivity; conductivity/total dissolved solids; and salinity. |

| อุปกรณ์ควบคุมการทำงาน อุปกรณ์ตั้งเวลาปิด-เปิด – Controllers |

|

4130 Traceable? Temperature Controller |

Automatically turns equipment on/off at set temperatures. Includes a time controller. |

|

4190 Traceable? Humidity Controller |

Turns equipment on/off at RH set point. Three-button operation is easy and fast. |

|

5010 Traceable? Lab Controller |

1568 On/Off switchings. Set countdown On/Off switchings. |

|

5050 Traceable?Timer Switch Controller |

Program up to 196 switchings per week. Digital display. Battery backup. |

|

5055/56 24-Hour & Traceable? 7-Day Controller |

Eight outlets. Pins constantly display all time settings. Raise or lower pins to set trip times. |

|

5057-5058 Traceable? Walkaway Controllers |

Switch equipment on/off instantly with manual override. |

|

5060, 5070 24-Hour/7-Day Controller |

Easy to use. Set any 15-minute increment or 2-hour increment. Repeats daily or weekly. |

|

5090 Traceable? Outlet Controller |

14 Switchings per day, up to 196 switchings per week. |

|

5095 Traceable? Countdown Controller |

Turns any piece of equipment on or off at the end of a set time. Nicad backup battery. |

| เครื่องนับจำนวน – Counters |

|

3125 Hand Tally Counter |

Easy-to-use, four-digit unit records up to 9999. Numbers instantly and automatically return to zero. |

|

3127 Digital Counter |

Counter reads to 99,999. Water-resistant. ABS plastic case. Tactile click buttons. |

|

3129 Digital Key-Chain Wristband Counter |

Reads to 99,999 and has a button click for count confirmation and recessed “no accident” reset. |

|

3130-3132 Touch Counter |

9999-digit counter. One-touch operation simultaneously counts and makes a mark. |

|

3133 Counter Pen |

Reads to 99,999 and is a combination marker and digital counter designed for the lab and plant. |

| เครื่องวัดค่าความชื้นสัมพัทธ์ – Humidity |

|

4082 Traceable? Memory Humidity/Temperature |

Displays ambient and probe temperatures. Remembers high/low readings. LCD digits are 1/2 inch high. |

|

4080, 4085 Traceable? Hum./Temp./Dew Point |

Fast response model, displays 0.01% RH and temperature. |

|

4087 Traceable? General Purpose Hygro./Therm. |

Simply point and read the result. Humidity range of 10.0 to 95.0%. |

|

4088 Traceable? Hygrometer/ Thermometer |

Self-contained. Requires no adjustment or maintenance. |

|

4093 Traceable? Humidity/Temperature Pen |

Memory recall, 30-Second response time, 3/4-inch-high display, Humidity/Temperature Pen with memory makes it easy to monitor any location |

|

4094-4096 Traceable? Digital Hum./Temp. Meter |

Shows the exact air conditions. Memories store min/max readings. Range is 25 to 95% RH. |

|

4154 Traceable? RH/Temp. Monitor w/Alarm |

Remote humidity and temperature sensor with high/low alarms and min/max memories. |

|

4180, 4181 Traceable? Printing Hygro./Therm. |

Provides permanent hard-copy results. Answers in less than 10 seconds. |

|

4184 Traceable? Jumbo Hum./Temp. Meter |

External thermometer probe with a 10-foot cable. Display is updated once per second. |

|

4185, 4385 Traceable? Memory Hygro./Therm. |

Temperature and relative humidity, 10.0 to 95.0% RH and 0.0 to 199.9°F and –18.0 to 93.0°C. |

|

4186 Dial Hygrometer/Thermometer |

Provides humidity and temperature readings in an easy-to-read dial format. |

|

4187 Traceable® Humidity /Thermometer Meter |

Analog Recorder Output. Humidity range is 10.0 to 95.0% RH. 100 hours of continuous readings. |

|

4189 Traceable® Humidity /Thermometer |

Hygrometer/Thermometer with computer output. Min/Max memories. |

|

4192 Traceable® Humidity-On-A-Card |

Easy-to-read humidity cards indicate both the current humidity and the maximum humidity attained. |

|

4247 Traceable®Hygro/Therm/Baro/Dew Point Pen |

Measure temperature, humidity, barometric pressure and dew point in the palm of your hand. At the press of a button, unit recalls minimum/maximum readings. |

|

4332 Enviro-Meter™ |

Provides in a single handheld package an anemometer, humidity meter, light meter and two thermometers. |

|

4380 Traceable®Hum./Therm. with Remote Sensor |

Radio-Signal Remote. Read humidity and temperature from 100 feet away. Reads up to three modules. |

|

4392 Traceable®Pocket Dew Point/Hygro./Therm. |

Shows humidity, dew point, and temperature. Not affected by condensation. |

|

4410 Traceable® Wet-bulb/Hum./Temp. Alarm |

Shows humidity, dew point, and temperature. Sounds high/low alarms. Provides minimum and maximum memory readings. |

| เครื่องวัดค่าความสว่างของแสง – Light Meter |

|

3248 Traceable® Pocket Digital Light Meter |

Bright 1/2-inch-high digits make it an easy to read pocket light meter. |

|

3247 Traceable® Light Meter Pen |

Designed for intuitive, easy operation by everyone. |

|

3251Traceable® Dual-Range Light Meter |

Reads both lux and foot-candles. Analog output of 0.1 millivolt per digit. |

|

3252 Traceable® Dual-Display Light Meter |

Displays lux or foot-candles. Serial RS-232 output. Recalls highest, lowest and average readings. |

|

3253 Traceable® Ultraviolet Light Meter |

Displays readings in uW/cm2 and mW/cm2. Serial RS-232 output. Recalls highest, lowest and average readings. |

เครื่องวัดค่าแรงดันและระดับสุญญากาศระบบเปิด – Manometers

– Manometers |

|

3460-3469 Traceable® Manometer/Vac. Gauge |

Differential feature permits reading the difference of the pressure or vacuum between two different sources. |

| แว่นขยาย – Magnifiers |

|

3350-3352 Illuminated Magnifier |

Magnifiers provide an in-focus and highly defined view of surface details and illuminating uniformly. |

|

3355, 3356 Illuminated Microscope |

Pocket Microscope magnifies view. Case is chemical- and shock-resistant ABS plastic. |

|

3357 Magnifier Lamp |

Convenient front handle provides fingertip control to rise, lower, and pivot. |

|

3430-3436 Hands-Free™ Fold-up Magnifiers |

Perfect focus with zero distortion. Portable with a scale on the base for measuring. |

| เครื่องวัดค่าความชื้น – Moisture |

|

4310 Traceable® Moisture Meter |

Displays material, wood, wood product, and paper moisture content 9.0 to 30.0%. Features memory. |

| เครื่องวัดค่าออกซิเจน – Oxygen Meter |

|

4319 Traceable® Dissolved Oxygen Pen |

Measure dissolved oxygen pen reads to 100% air saturation in the palm of your hand. |

|

4320 Traceable® Dissolved Oxygen Meter |

Displays oxygen concentration in air and in solution. RS-232 output. |

| เครื่องวัดแรงดันและระดับสุญญากาศระบบปิด – Pressure/Vacuum |

|

3165, 3166 Traceable® Pressure/Vacuum Gauge |

Eight measuring ranges. Use with all gases and liquids compatible with 316 stainless steel. |

| ปั๊มดูดจ่ายของเหลว- Pumps |

|

3384-3389 Variable-Speed Pump |

Compact, variable-flow, bi-directional, self-priming peristaltic pumps offer precise flow deliveries. Dial in the flow rates. |

|

3388 Variable-Flow Chemical Transfer Pump |

Pumps fluids with a viscosity to 200 centipoises. Suction lift is 10 feet wet, 4 inches dry. Reverses for ease in draining. |

| เครื่องวัดความดังของเสียง – Sound Meter |

|

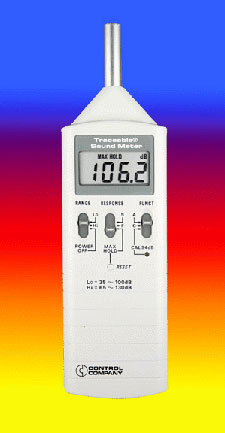

4335 Sound Level Meter |

Memory stores the highest reading achieved. Adjustable response time. Three-decibel ranges. |

|

4336 Traceable® Analog Sound Meter |

Measures in 7 ranges. Low battery checker. |

| นาฬิกาจับเวลา – Stopwatches |

|

1025 Traceable® 60 Memory Stopwatch |

60-memory, stopwatch with countdown. 3-line display. |

|

1030 Traceable® Digital Stopwatch |

Single-action, time-out, interval-split, and continuous timing. Times to 9 hrs, 59 min, 59 sec, and 99 hundredths. |

|

1031 Traceable® Decimal Stopwatch |

Single-action, time-out, interval-split, and continuous timing. Times to 19 hours, 59 minutes, 59 seconds, and 99 hundredths. |

|

1034 Traceable® 2-Display Digital Stopwatch |

Single-action, time-out, interval-split, and continuous timing. Times to 9 hrs, 59 min, 59 sec, and 99 hundredths. |

|

1035 Traceable® Countdown Stopwatch |

Set by turning a dial. Countdown and alarm timing in increments of 1 min, 5 min, 10 min, up to 45 min. |

|

1037/1044 Traceable® Stopwatch/Chronograph |

Times to 24 hours. Chronograph. Single-action, time-out, cumulative split, and continuous timing. |

|

1042 Traceable® Waterp./Shockp. Stopwatch |

Times to 24 hours. Single-action, time-out, cumulative split, and continuous timing. Waterproof to 3 atms. |

|

1043 Traceable® Three-Button Stopwatch |

Start/stop, time-out, cumulative split, and continuous rollover timing. Time and date. |

|

1045 Traceable® Water-/Shock-Resist Stopwatch |

Times to 24 hours. Single-action, time-out, cumulative split, continuous timing. Water-/shock resistant. |

|

1047 Traceable® Big-Digit Stop./Chrono. |

LCD digits 0.4 inches. Single-action, time-out, and cumulative split. Times up to 24 hours. |

|

1048 Traceable® Stopwatch/Repeat Timer |

Countdown time from 10 hours to 1/10 of a second. Repeat cycle automatically continues until stopped. |

|

1051 Traceable® Jumbo-Digit Stopwatch |

1/2-inch high digits. Resolution 1/100 of a second. Chronograph. Water-resistant. |

|

1052 Traceable® 300 Memory All-Function Stop. |

300 Memory All-Function Stopwatch, countdown timer, and handy clip. Stopwatch times to 9 hours, 59 minutes, 59 seconds, 99 hundredths. |

|

1221 Traceable® Digital Bench top Timer |

Digital display is 3/4 inch high. Times up from 0.01 sec. to 9 hrs, 59 min, 59 sec, and 99 hundredths of a sec. |

|

8529 Mechanical Stopwatch |

Analog 1/10 second stopwatch with metal case. |

| เครื่องวัดค่าความเร็วรอบ – Tachometers |

|

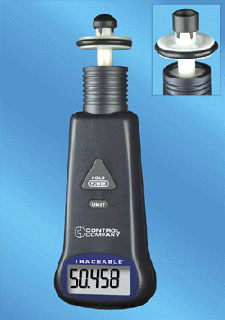

4059 Traceable® Touchless/Contact Dig. Tacho. |

3-seconds response time. Recalls the highest, lowest, and last reading. |

|

4060 Traceable® Digital Laser Tachometer |

1-second response time. Recalls the last reading at any time. |

|

4261 Traceable® Tachometer Touch |

Contact measurements for rotating surfaces |

|

4262 Traceable® Tachometer w/Red LED Pointer |

Red LED light, touchless handheld point-and-shoot tachometer |

| เครื่องัดค่าอุณหภูมิแบบดิจิตอล – Thermometers |

|

4000 Traceable® Digital Thermometer |

The most accurate thermometer. Min/max memory. Data Logger. Resolution of 0.001°. |

|

4003 Traceable® Waterproof Type K Thermometer |

One of the most technically advanced, fastest-reading, yet easy-to-use thermometers ever designed. |

|

4004 Traceable® Big-Digit Type K Thermometer |

Easy to read big digits measure over 5/8-inch-high digits are readable from 15 feet away. |

|

4007 Traceable® Memory Wide-Range Thermometer |

Expansive range of -200 to 1370°C and a backlight for dark areas. |

|

4008 Type-K Surface Probe |

Stainless-steel with handle, triple purpose |

|

4014 Stainless-Steel Type-K Probe |

Triple purpose: liquids, air/gas, and semisolids. |

|

4015 Traceable® Total Range Thermometer |

Complete range from -200 to 1370°C. Updated twice a second. |

|

4021 Micro Probe |

Micro probe for Cat. No. 4000 |

|

4022 Surface Probe |

Surface probe for Cat. No. 4000. |

|

4023 Air Probe |

Air probe for Cat. No. 4000. |

|

4025,4026 Traceable® Expanded-Range Therm. |

Easy to use 3-position switch and 2 probes so you can monitor multiple tests. |

|

4028 Type-K Beaded Probe |

Fast response, type-K thermocouple. 4 feet long. |

|

4029 Traceable® Dual Channel Thermometer |

Simultaneously shows 2 separate temperatures from 2 probes or difference between them. |

|

4039, 4339 Traceable® Waterproof Thermometer |

Waterproof and shockproof |

|

4040 Traceable®Therm./Clock/Humidity Monitor |

Displays time of day, temperature, and humidity. A.M./P.M. or 24-hour military time. |

|

4042-4344 Traceable® Digital Dial Thermometer |

Always on thermometer. Large temperature range. |

|

4045 Traceable® Digital Thermometer |

Probe holder. Settable high/low temperature alarms. |

|

4100-4101 Traceable® Printing Thermometer °F/°C |

Printing Thermometer provides permanent record, prints time and date |

| เครื่องตั้งเวลาปลุกเตือน เครื่องจับเวลา นาฬิกาจับเวลา – Timers |

|

1004 Compact Timer |

Mechanical timer from 1 to 120 minutes. Loud, 5-second ring. |

|

1021 Traceable® Bench Timer |

Twelve timing channels. Four timing modes. Audible alarm. |

|

1060 Traceable® Pocket Timer |

Clip it. 60-second buzzer. Three-button operation. |

|

1062 60-Minute Interval Timer |

Mechanical timer from 0 to 60 minutes. |

|

1092-1093 SX-Timer™ – Quick-Timer™ |

Wind up, analog timers forever eliminate battery replacements. |

|

1221 Traceable® Digital Bench top Timer |

Digital display is 3/4 inch high. Times up from 0.01 sec. to 9 hrs, 59 min, 59 sec, and 99 hundredths of a sec. |

|

3260 Traceable® Time and Number Printer |

Time-stamp and number all your paperwork with electronic precision. |

|

5000 Traceable® Three-Channel Alarm Timer |

Displays 3 different times simultaneously. Loud decibel for noisy areas and low for quiet areas. |

|

5002 Traceable® Original Lab Timer |

Program 3 activities from 9 hours, 59 minutes, 59 seconds to 1 second. Distinct alarm. |

|

5004 Traceable® Four-Channel, Big-Digit Timer |

Can be seen from across the room. High-decibel alarm. Set up to 4 channels. |

|

5005 Eight-Channel Alarm Timer |

All-purpose, Eight-Channel Alarm Timer with volume control. 100-hour timing capacity. |

|

5006 Traceable® Two-Memory Timer |

Counts up/down from 23 hours, 59 minutes, 59 seconds. AM/PM or 24-hour format. |

|

5007 Traceable® Lab-Top Timer |

Large keys and any-angle viewing. Counts down from 24 hrs to 1 sec. Memory is locked until changed. |

|

5008 Traceable® Three-Line Alarm Timer |

Times simultaneously. Channels may be started individually or concurrently. |

|

5009 Traceable® Big-Foot Timer |

One inch high LCD digits. Simultaneous programming of 3 different activities from 99 hrs, 59 min, 59 sec to 1 sec. |

|

5011 Traceable® GIANT-DIGIT™ Countdown Timer |

View giant size digits on your bench timer from across the lab. |

|

5012 Traceable® Multi-colored™ Timer |

Add color to your lab, 4-Channel Multi-Colored™ Timer, personalize your timer, show your distinct style with customized bold colors—a fresh look for the lab |

|

5014 Extra-Extra-Loud Traceable® Timer |

One-hundred-decibel alarm. Memories returns to previous countdown time at the touch of a button. |

|

5015 Traceable® Talking Timer |

Voice periodically reminds you of countdown time remaining to zero. Eliminates looking at the timer. |

|

5020 Traceable® Alarm Timer/Stopwatch |

Counts down from 100 min. Stopwatch counts up to 60 min and rolls over to zero and continues timing. |

|

5021 Traceable® 100-Hour Alarm Timer/Stop |

Counts up/down with alarm. Numbered keys 0-9. Counts down from the memory. |

|

5022, 5023 Traceable® Jumbo Timer |

Simultaneous programming of 2 different activities from 24 hours to 1 second. One-inch high LCD digits. |

|

5025 Traceable® Triple-Display Timer |

Alarm sounds for 1 min. Memory returns to the previously programmed time. |

|

5026 Traceable® QC Timer |

Count down and alarm timer combines easy, 3-button operation with giant-size digits. |

|

5027 Traceable® Triple-Purpose Timer |

3/4-inch-high digits. Countdown/up, AM/PM or 24-hour format. Full keyboard 0-9 keys. |

|

5028 Traceable® 99M/59S Timer |

Counts down from 99 minutes in second increments with 3-button ease and big-digit visibility. |

|

5030 Traceable® Memory Timer |

Countdown from 24 hrs in increments of 1 min. Seconds are displayed the last 10 minutes. |

|

5035 Traceable® Advanced Memory Timer |

Remembers the last time set, counts down/up, alarms from 24 hrs in increments of 1 sec. |

|

5036 Traceable® Water-Resistant Timer |

Audible alarm sounds for 1 minute or can be manually turned off. |

|

5037 Traceable® Credit Card Timer |

Counts down from 99 minutes, 59 seconds with a 1 second resolution. |

|

5040 Traceable® 100-Hour Timer |

Counts both up and down to 100 hours. Alarm turns off manually or is silenced after 1 minute. |

|

5041 Traceable® Key-Chain Timer |

4-digit LCD display. Countdown in min from 20 hrs. Alarm sounds for 60 sec, or may be silenced manually. |

|

5042 Traceable® Fingertip™ Timer |

Three button operation. Repeat memory. Counts down from 99 minutes, 50 seconds in 1-second increments. |

|

5043 Traceable® Tie Timer |

36-inch lanyard. Digits are 0.45” high. Counts down and alarms from 24 hours to 1 second. Memory. |

|

5045 Traceable® Digital Timer Plus |

Six-digit LCD always shows the time remaining in hours, minutes, and seconds |

|

5046 Traceable® Clip-It Timer |

Three-button operation. Clip-It Timer counts down, alarms, and functions as a stopwatch. |

|

5047 Traceable® Touch Timer |

Four-digit display. Count down and alarm from 19 hours, 59 minutes to 1 minute. Two-button operation. Loud-beeping alarm. |

|

5048 Traceable® Multiple Alarm Timer |

96 alarms daily. A bar graph shows the time line and arrows show every alarm time set. Time of day. |

|

5122 Traceable® Instant-Recall Memory Timer |

Ideal timer to dedicate to routinely timed test |

|

5127 Traceable® Double Display Timer |

Simultaneously program two different activities |

|

5132 Traceable® Nano™ Timer |

Ultra small design, two channel easy operation, time of day, and 2-1/2 x 2-inch size. |

|

8906 Traceable® LCD Timer |

Compact timer is a timer, stopwatch and clock |

| เครื่องมือ อุปกรณ์ที่จำเป็นสำหรับห้องปฏิบัติการ – Tools |

|

3419 Ultrasonic Automatic Measuring Meter |

Simply point and shoot to measure distance, area, and volume. LCD displays measurement. |

|

3475 Traceable® SpatulaBalance™ |

Unique spatula both scoops material and instantly displays weight. |

| ผ้าเช็คเลนส์ เครื่องมือวิทยาศาสตร์ เครื่องแก้วแบบไม่มีขุย – Wipes |

|

2050 Certified Cheesecloth Wipes |

Reagent-grade quality. Excellent filtering material. Lint-free. |

|

2060-2065 Clean-Wipes |

Individually dispensed wipes are handy and ready for instant use. Lint-free. New universal clean-up tool. |

|

2067 Optik-Wipes |

Works for non-reflective and UV-resistant coated glasses. Prevents fogging. Nonwoven cloth is premoistened. |

| เครื่องวัดสภาพอากาศ – Weather Station |

|

4250 Wireless Weather Station |

Temp, RH, dew point, barometric pressure/pressure trend, weather forecast, wind direction/speed, wind chill and more. |

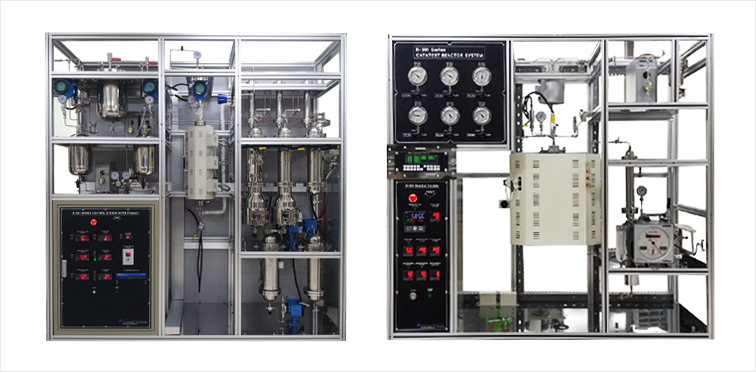

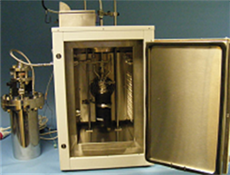

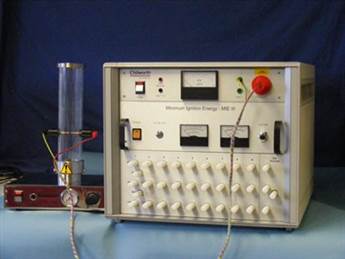

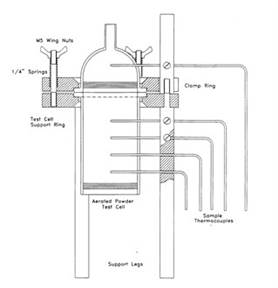

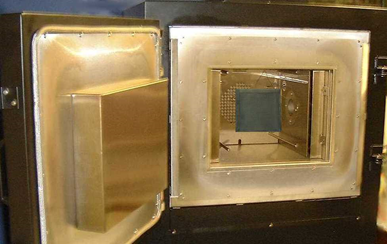

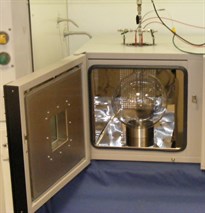

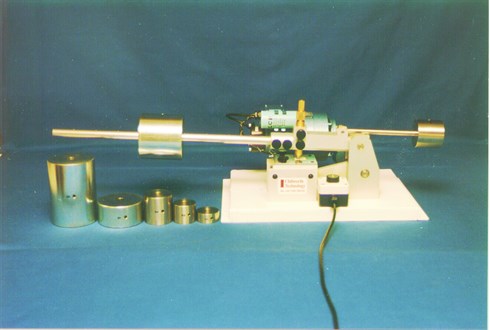

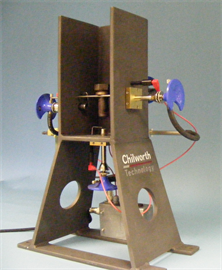

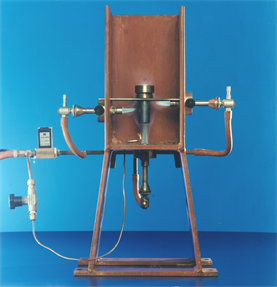

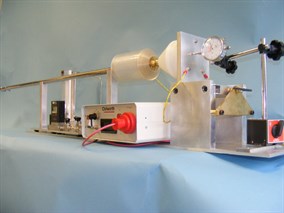

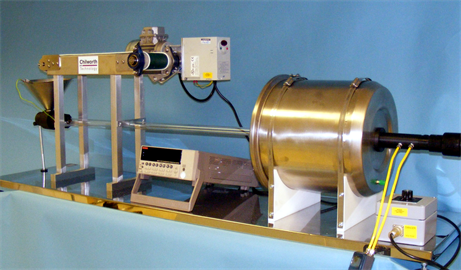

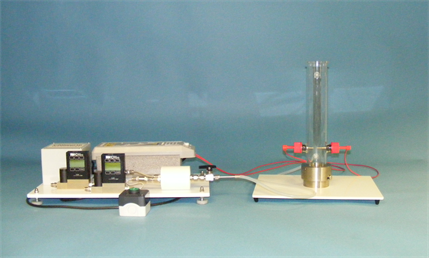

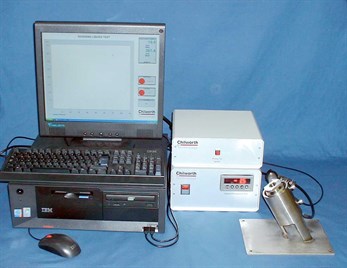

R-201 Series Reactor System

R-201 Series Reactor System

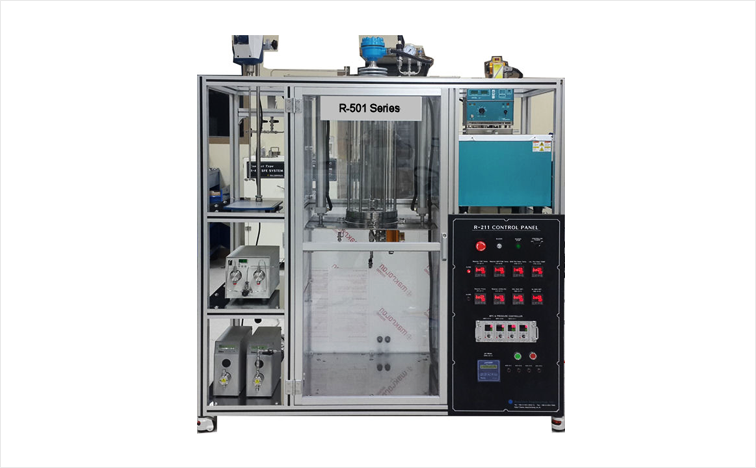

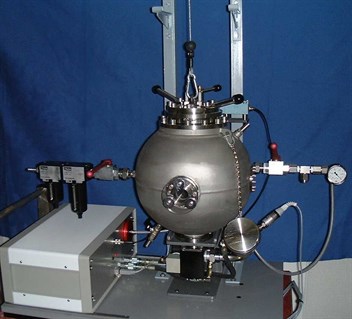

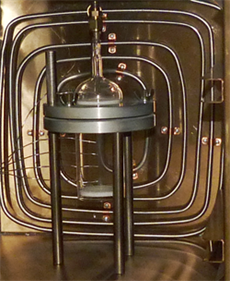

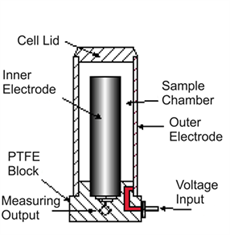

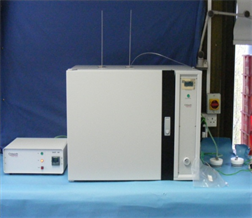

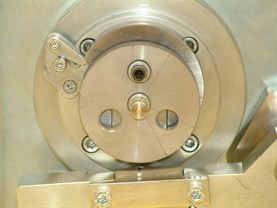

Pressure Vessel

Pressure Vessel