ผู้ผลิตเครื่องทดสอบคุณภาพน้ำนมดิบ นมผง เนย ชีส และผลิตภัณฑ์ที่ทำจากนม (Dairy Products) เช่น โยเกิร์ต นมเปรี้ยว เป็นต้น เครื่องวัดค่าไขมันด้วยวิธีปั่นเหวี่ยง (Gerber Butyrometer Method) เครื่องวัดค่าจุดเยือกแข็ง (Freezing Point) ของน้ำนมดิบ เครื่องวัดความหนืดแบบ Consistometer เครื่องวัดการไหลเท (Pouribility) เครื่องวัดค่าความหนาแน่นของนม เครื่องวัดค่าความหวาน เครื่องวัดกรดแลคติก เครื่องนับจำนวนเชื้อจุลินทรีย์ (Colony Counter) เป็นต้น

· Milk dipper

· Butter triers

· Cheese triers

· Dosing Syringes Original Gerber

· Tilt measure

· Automatic measure permanent

· Tripods for permanent automata

· Pipets

· Milk butyrometer

· Skim milk butyrometer

· Cream and ice cream butyrometer

· Cheese and curt butyrometers

· Butter butyrometers

· Dry milk butyrometers

· Gerbal-stoppers and regulating pins

· Conical rubber stoppers

· Glass beaker

· Butyrometer racks

· Cleaning brush

· Waterbath pot

· Waterbath WB 12 without

circulation pump

· Waterbath WB 22 Pump with

circulation pump

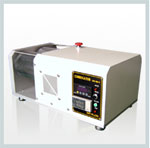

· Milk centrifuge Gerber Universal

· Milk centrifuge Gerber Compact III

· Milk centrifuge Gerber Micro II

· Milk centrifuge Gerber Micro III

Centrifuge

Gerber Universal

Mehrzweckzentrifuge

für das milchwirtschaftliche Labor mit 3 vorprogrammierten Drehzahlen für:

-Gerber Butyrometer: 350 x g

– Löslichkeitsindex in Milchpulver: 164 x g

– Röse-Gottlieb/Mojonnier: 80 x g

1 variable Drehzahl (200 bis 1300 U/min, auf Kundenwunsch)

Specification

-Timer von 0 bis 255 min

– Automatische Bremse

– Heizung (optional) mit variabler Temperaturregelung bis 65 °C

(1200 W)

– Digitale Mikroprozessorkontrolle mit LCD-Anzeige für Drehzahl,

Laufzeit, Temperatur und Fehler

– Deckelverriegelung

– Stahlgehäuse (BxTxH): 64 x 64 x 45 cm

– mit Universalrotor für 12 Plätze ohne Einsätze

(separat bestellen) oder mit Spezialrotor inklusive 36 Hülsen

|

Type

|

03.3110

|

03.3111

|

03.3112

|

03.3113

|

|

Netzanschluss (VAC/Hz):

|

230/50

|

115/60

|

230/50

|

115/60

|

|

Heizung:

|

nein

|

nein

|

ja

|

ja

|

Download product information

Universal Rotor

Je nach Untersuchungsmethode stehen 4 verschiedene Einsätze zur Verfügung.

Specification

|

Butyrometer-Einsatz

Gerber:

|

aus

rostfreiem Stahl,

Ø innen 26 mm

|

|

Löslichkeits-Einsatz

ADPI:

|

aus

rostfreiem Stahl,

Ø innen 31 mm

|

|

Mojonnier-Einsatz:

|

aus

rostfreiem Stahl

|

|

Babcock-Einsatz

(auf Anfrage):

|

aus

rostfreiem Stahl,

Ø innen 38 mm

|

Type

· Butyrometer Einsatz Gerber für Butyrometer, Löslichkeitsröhren und Röse-Gottlieb-Röhren

· Löslichkeits-Einsatz ADPI für Löslichkeitsröhren nach ADPI

· Mojonnier-Einsatz für Mojonnierröhren

· Babcock-Einsatz für Babcock-Flaschen

Download product information

NEW – Milk centrifuge Gerber Compact III

With our new multipurpose centrifuge Compact III these methods can be carried out:

· Fat determination according to Gerber and Babcock

· Solubility determination according to Gerber and ADPI

The Gerber centrifuge Compact III with high safety standards and reliability and

these product features:

· Strong sheet steel housing with an acid-resistent paint work

· Cover lock to prevent opening of the centrifuge during Operation

· Unbalance shut-off through uneven filling or sudden glass break

· Motor with elastic bearing for smooth run

· Increased precision thanks to controlled speed

Download product information

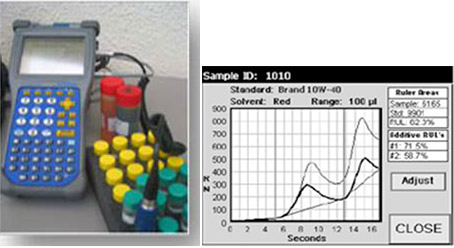

Centrifuge Gerber Micro II

Small centrifuge for the determination of fat in milk and dairy products and

solubility of milk powder acc. to Gerber.

Specifications

· Timer

· Automatic brake

· Heating (option) with variable temperature setting up to 65 °C

· Microprocessor control with digital reading

· Cover lock

· Steel casing (WxDxH): 43 x 46 x 28 cm

· Incl. rotor and bushing

|

Typ

|

03.2250

|

03.2251

|

03.2260

|

03.2261

|

|

Voltage

(VAC/Hz):

|

230/50

|

115/60

|

230/50

|

115/60

|

|

Qty. Butyrometer:

|

8

|

8

|

12

|

12

|

Download product information

NEW – Milk centrifuge Gerber Micro III

With our small centrifuge Micro III these methods can be carried out:

· Fat determination according to Gerber or

· Fat determination according to Babcock

The Gerber centrifuge Micro III with high safety standards and reliability and

these product features:

· Strong sheet steel housing with an acid-resistent paint work

· Cover lock to prevent opening of the centrifuge during operation

· Motor with elastic bearing for smooth run

· New – Increased precision thanks to controlled speed

· New – Unbalance shut-off through uneven filling or sudden glass break

Download product information

· Mojonnier analyzer

· Centriguge Gerber Universal

· Shaking machine Rototube

· Extraction flask acc. to Mojonnier

· Extraction flask acc. to Roese-Gottlieb

· Stoppers for extraction flasks

· Rack for Mojonnier flasks

· Siphon fitting to Roese-Gottlieb flasks

To determine the specific weight of milk.

· Thermolactodensimeter Gerber large model with thermometer

· Thermolactodensimeter Gerber small model with thermometer

· Lactodensimeter Gerber without thermometer

· Lactodensimeter Gerber without thermometer with density scale

· Thermolactodensimeter Quevenne with thermometer

· Lactodensimeter Quevenne without thermometer

To determine the specific weight of dairy products.

· Hydrometer for condensed milk

· Hydrometer for yogurt and cocoa

· Hydrometer for buttermilk serum

· Hydrometer for whey

To monitor and adjust the fat determination conducted by Gerber.

· Hydrometer for sulfuric acid

· Hydrometer for amyl alcohol

To determine the specific weight of brines and alcohols.

· Hydrometer for brine acc. to Baumé

· Hydrometer for alcohol

Cryoscope Gerber Standard

Simple freezing determining device for detecting extraneous water contents in the

raw milk.

Specifications

Double walled, isolated cooling container, without an electric stirrer, including sample tubes, stirrers, thermometers and calculator for added water

A

Cryoscope Gerber C1 and C1A

To reliably and rapidly determine the freezing point in milk acc. to ISO 5764/IDF

108. During the daily inspection of water content in raw milk, the device would be

working extremely quietly. The dynamic cooling system, allows a maximum sample throughput even at ambient temperatures up to 35 °C.

Specifications

|

Test

time:

|

approx. 90

sec

|

|

Sample

volume:

|

2.0 ml

or 2.5 ml

|

|

Resolution:

|

0.1

m°C/m°H

|

|

Range:

|

0 bis

-1500 m°C/m°H

|

|

Repeatability:

|

± 2

m°C/m°H

|

|

Temperature:

|

15-35 °C

|

|

Voltage:

|

110-240

VAC/50-60 Hz

|

Including standard solutions, heat transfer solution, coolant and test tubes

Type

· Cryoscope Gerber

C1 manual for 1 sample

· Cryoscope Gerber

C1A automat for 12 samples

Download product information

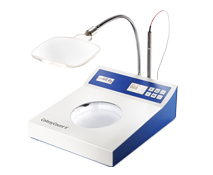

Colony counter ColonyCount V

To count bacterial colonies with reliability and efficiency. The contact surface of the petri dish is pressure sensitive. Tapping the colony on the tray with the count pint will an acoustic and optical count signal triggered.

Specifications

|

Display:

|

Grafic

display with membrane keyboard

|

|

Standard

magnifier glass:

|

2-x magnification

|

|

Lighting:

|

LED side

and from below (LDG)

|

|

Petri dishes:

|

up to Ø

120 mm

|

|

Voltage:

|

100-240

VAC/50-60 Hz

|

Including Wolffhuegel disk, adapter fpr petri dishes Ø 120/90 mm, magnifier and marker

Download product information

Accessories for ColonyCount V

In addition to standard equipment, you can yet select another optional accessories.

Type

· Thermal printer

· Sensor pen for external counting

· Memory card 2 GB

· Adapter set for petri dishes Ø 120-50/60/80/90 mm

· Adapter for petri dishes Ø 120/50 mm

· Adapter for petri dishes Ø 120/60 mm

· Adapter for petri dishes Ø 120/80 mm

· Adapter for petri dishes Ø 120/90 mm

Download product information

· Sediment test pump

· Sediment tester Gerber

· Sediment tester Rapido

· Filter funnel for sediment test

· Filter for sediment test

· Flow out viscometer

· Nozzles for flow out viscometer

· Consistometer Bostwick

· Solumixer Universal

· Solumixer Standard

· Waring mixer

· Centrifuge tubes

· Jolting volumeter STAV II

· Jolting volumeter Gerber

· Mixer for the determination of miscibility and clumping

· Pourability Tester

Consistometer Bostwick

To measure the consistency, viscosity and flow-out time of liquids by measuring

the distance covered by the sample during a certain time.

Specifications

|

Application:

|

Food

industry

|

|

Volume

of sample (ml):

|

75

|

|

Dimensions (WxDxH-cm):

|

35x9x13

|

|

Material:

|

stainless

steel

|

|

Graduation

(cm):

|

0.5

|